Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

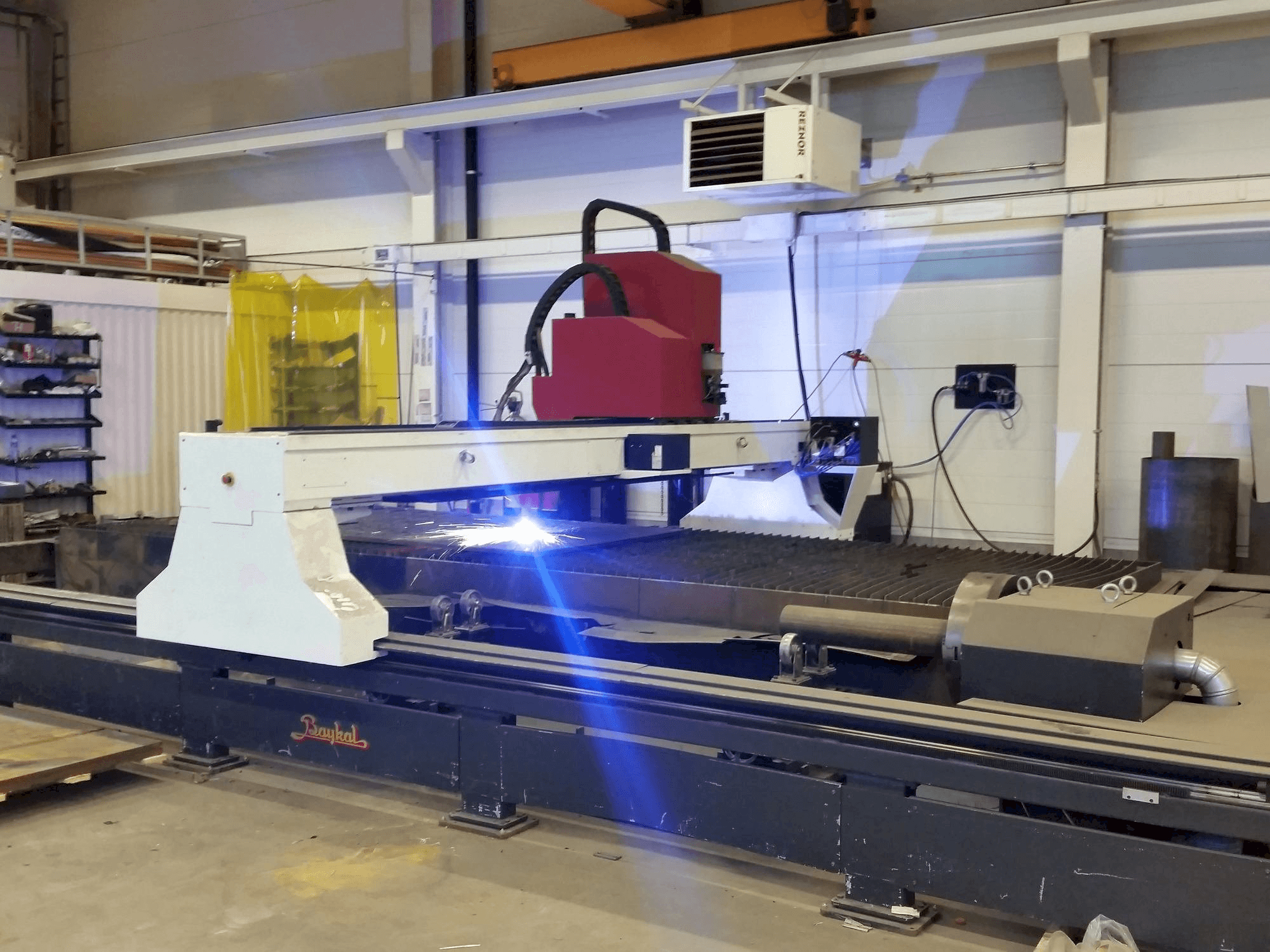

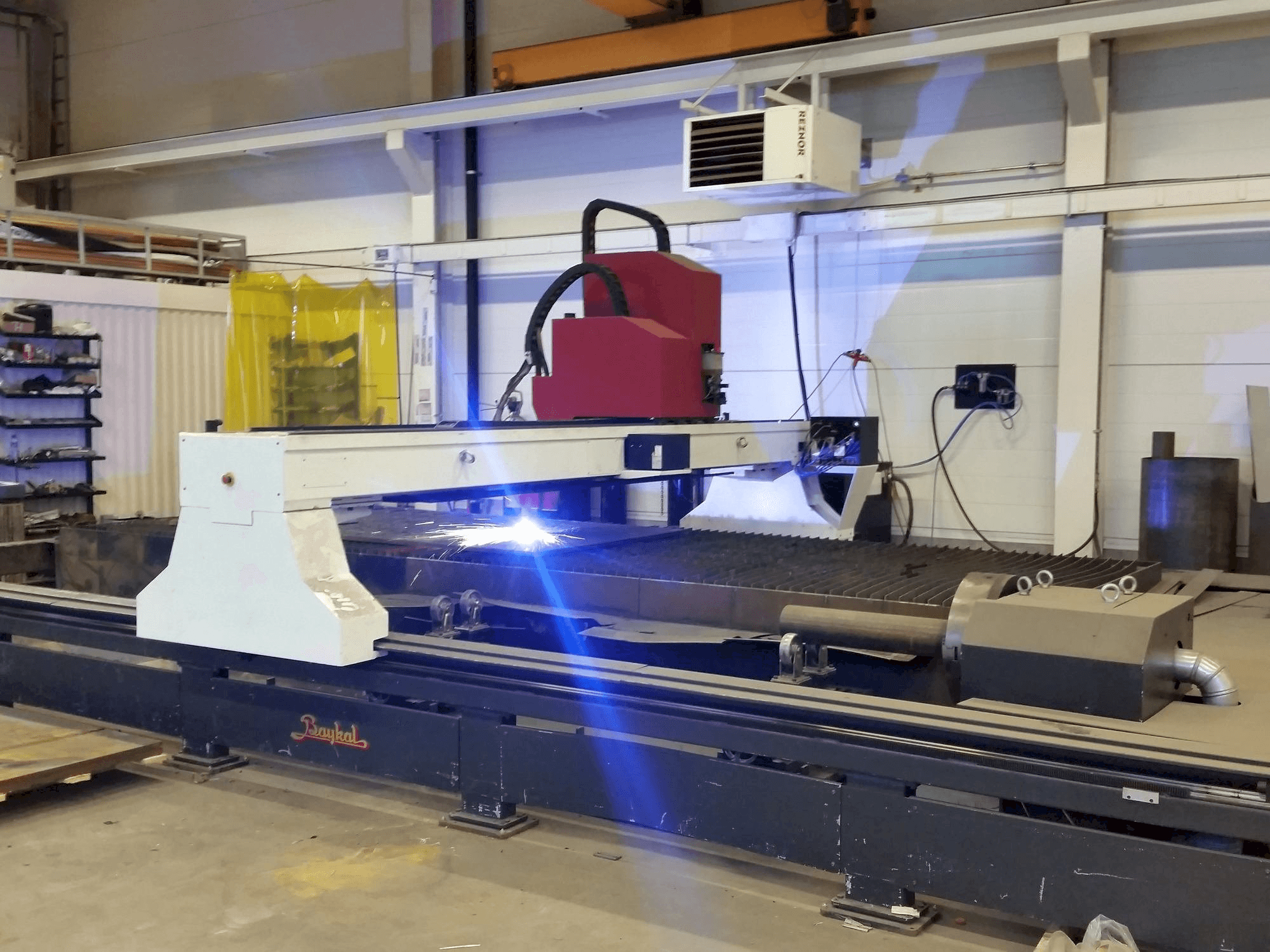

Baykal - BPL-H 2006 HPR 260XDNO-PLA-BAY-2015-00001

Sold

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Sheet Metal Machinery

- Baykal BPL-H 2006 HPR 260XD Plasma Cutting Machine

Show in original language

This Baykal BPL-H 2006 HPR 260XD Plasma Cutting Machine was manufactured in the year 2015. It is equipped with a Technos PC12 control unit. The machine has a positioning speed of Up to 20 000 mm/min.

Overview

- brand: Baykal

- year: 2015

- MODEL: BPL-H 2006 HPR 260XD

- application type: Cutting

- Location: Norway

- machine type: Plasma Cutting Machine

Technical Information - Baykal BPL-H 2006 HPR 260XD

Dimensions

- Table Length: 6400 mm

- Table Width: 2200 mm

Additional Information

Machine Benefits

Qualitative Machine Benefits

- The cutting table is independently constructed from the cross beam and machine frame, to achieve positioning accuracy under any weight on the table.

- The cutting head has sensors for automatic adjustment of the cutting head cutting height.

- Collision protection on the plasma cutting head, the machine comes with electrical equipment for: 400v

- Sectioned cutting table integrated with automatic extraction system, extraction hatches that open on the work surface for better extraction, plasma cutting head : including cable pull chain

- "high-definition type plasma supply unit, programming software for nesting/optimization of parts via pc, regulator : single output

- Manual/automatic gas console for selection of plasma and additive gases, high capacity air filter unit for dust and fume collection (optional), hose package : hose package for cutting source, gas supply : hose package for gas supply

- One set of consumables (nozzles, electrode, nozzle holder, manifolds etc), positioning speed : up to 20 000 mm/min

- Working temperature : between -10° c to +30° c, exhaust system : cnc operated with pneumatic hatches, motorsy axes : left and right side two brushless ac servomotors, traverse y axes : double-sided via rack and pinion drive, motor x axis : brushless ac servo motor, transverse x axis : via rack and pinion and gear drive

- Operation y axis : double-sided, two-way longitudinal operation, operation x axis : double-sided transverse operation, guide y axis : linear guides, guide x axis : linear guide, guide x axis : linear guide

- Plasma source : hypertherm hydefinition plasma hpr260xd with, auto gas console, control : technos pc12 ( made in the usa ) windows based, software package : lantek nesting software for pc ( lantek expert ii )

Technical Machine Benefits

- Pipe cutting function Ø50-600mm

- Bevel head

- 6-station drill and thread unit, drill max Ø20mm, thread max Ø16mm

- Stationary control panel instead of panel on cutting boom, positioned on the left side of the machine when viewed from the front.

- Cutting width : 2200mm

- Cutting length : 6400mm

- Double-sided synchronized servo drive on y axis = longitudinal movement of cutting head

- Single synchronized servo drive on x axis = transverse movement of cutting head

- Ac servo driven motors (brushless)

- Fast positioning speed 20 mt/min with ± 0. 05 mm positioning accuracy

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Sergi Guardia

Sergi Guardia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing