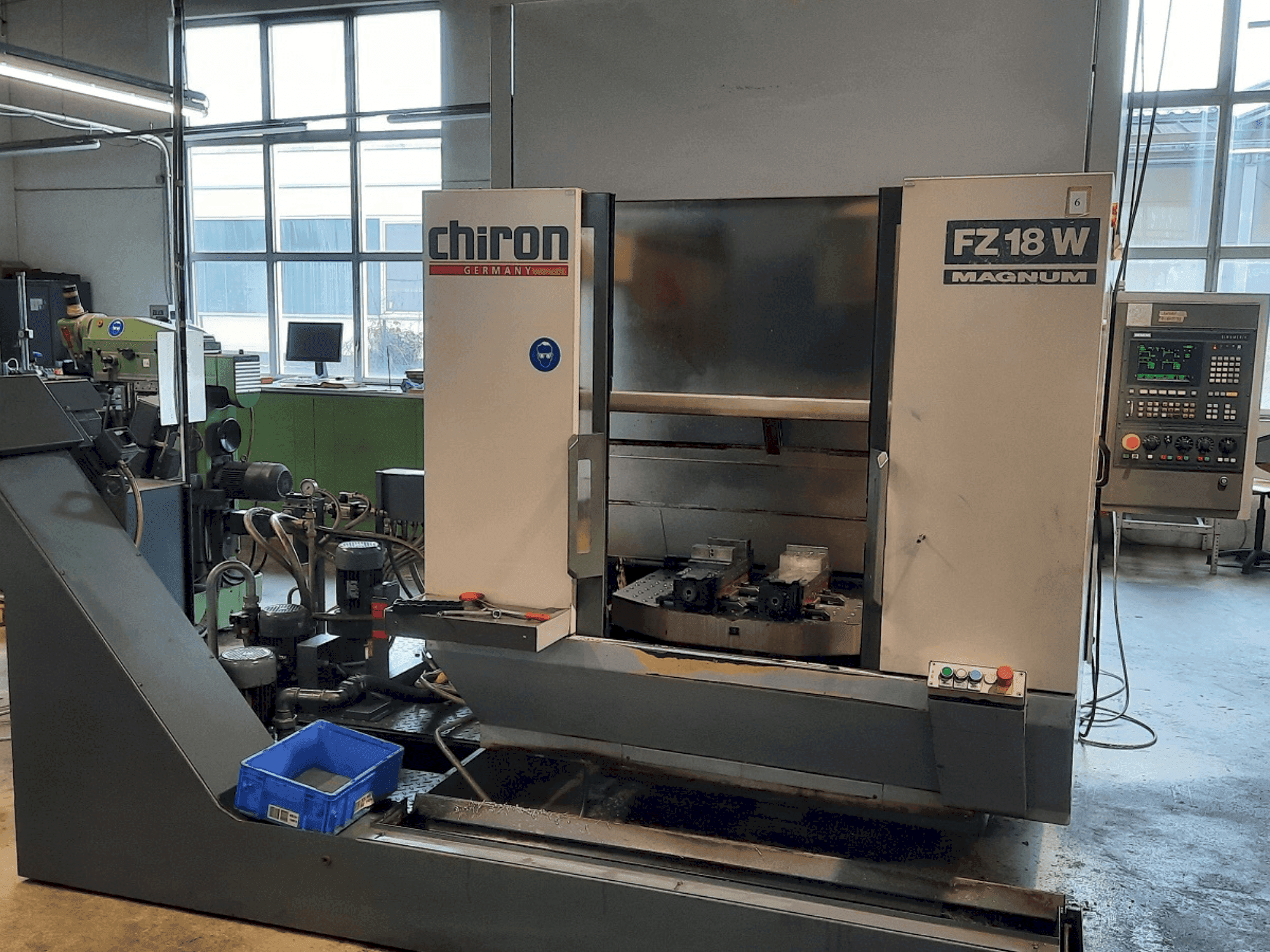

CHIRON - FZ 18 WDE-MIL-CHI-1996-00002

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used CHIRON FZ 18 W For Sale | gindumac.com

This 4-axis CHIRON FZ 18 W was manufactured in 1996, featuring a robust vertical machining center design. It includes a main spindle drive up to 13 kW, rapid traverse speed of 30 m/min, and a high-capacity automatic tool changer with 20 positions. The machine supports complex operations with SINUMERIK 810M control for precise 3D contouring. Ideal for high-demand environments, it also has dual chip conveyors with an advanced coolant system. Contact us for more information about this machine.

Overview

- brand: CHIRON

- year: 1996

- MODEL: FZ 18 W

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - CHIRON FZ 18 W

Control Unit

- Brand: SIEMENS

- Model: Sinumerik 810M

Main drive

- Spindle speed range: 20 - 7100 rpm 1/MIN

- Spindle motor power: 13 kW

- Number of axis: 4

Movement

- X-AXIS Movement: 630 mm

- Y-AXIS Movement: 400 mm

- Z-AXIS Movement: 425 mm

Tools

- Max weight: 5 kg

- Max tool diameter: 65 mm

Additional Information

Additional equipment

- 2.2 Chip Conveyors: Scraper belt, discharge height 1050 mm

- Steel Cover: In all axes

Machine Benefits

Technical Machine Benefits

- Spindle torque: 300 nm

- Rapid traverse speed: 30 m/min

- Feed drive: ac servo motor, indirect position measuring system

- Clamping surface: 2 x 850 x 470 mm with thread and bore pattern

- Max transport load per side: 250 kg (up to 400 kg with extended time)

- Workpiece change time: approx. 4. 0 s, increasing to approx. 7 s with max loads

- Automatic tool changer: 20 tool positions

- Tool specifications: steep taper 40 din, diameter 65 mm, diameter with free adjacent positions 180 mm, weight 5 kg

- Tool change time: 0. 9 s // chip-to-chip time: 2. 4 s

- Coolant system: 500-liter tank, with n-pump (200 ltr/min at 1. 5 bar) and hd-pump (20 ltr/min at 20 bar), hd circuit with 60 um cleaning

Extra Information

Safety: Electrically protected screwed splash guard with loading door Height: Approx. 2600 mm above floor, including machine light Control Panel: Mini control panel with start and acknowledge button for pallet organization Control Unit Control Type: SINUMERIK 810M - 3-axis contouring control Program Memory: 32000 characters (approx. 28000 characters freely available) Notable Features: Drilling cycles G81-G89, Circular interpolation, Program restart, Subroutine technique with parameters, Operator guidance, Simultaneous programming, Polar coordinates, Tool offsets, Intersection point/cutter radius path compensation, Zero offsets, 3D interpolation, Direct spindle speed programming, Chamfers and radii insertion, RS 232C connection, NC diagnostics, Machine diagnostics

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to CHIRON FZ 18 W

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

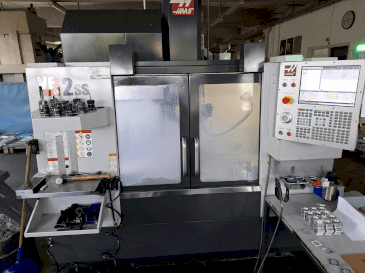

VF 2 SS

HAAS - Vertical Machining Centre

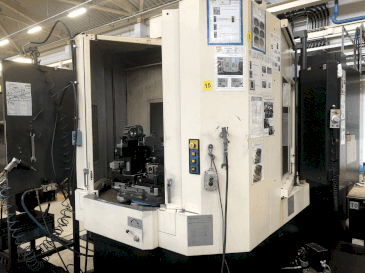

EC-400

HAAS - Horizontal Machining Centre

HM 6300

DOOSAN - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

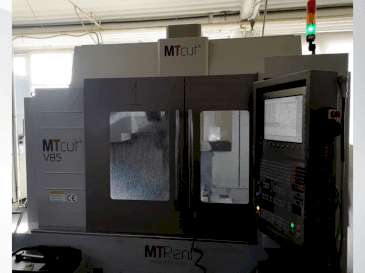

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

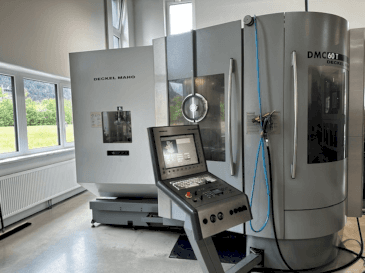

DMC-63V

DECKEL - Vertical Machining Centre

VTC-300C

Mazak - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre