Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

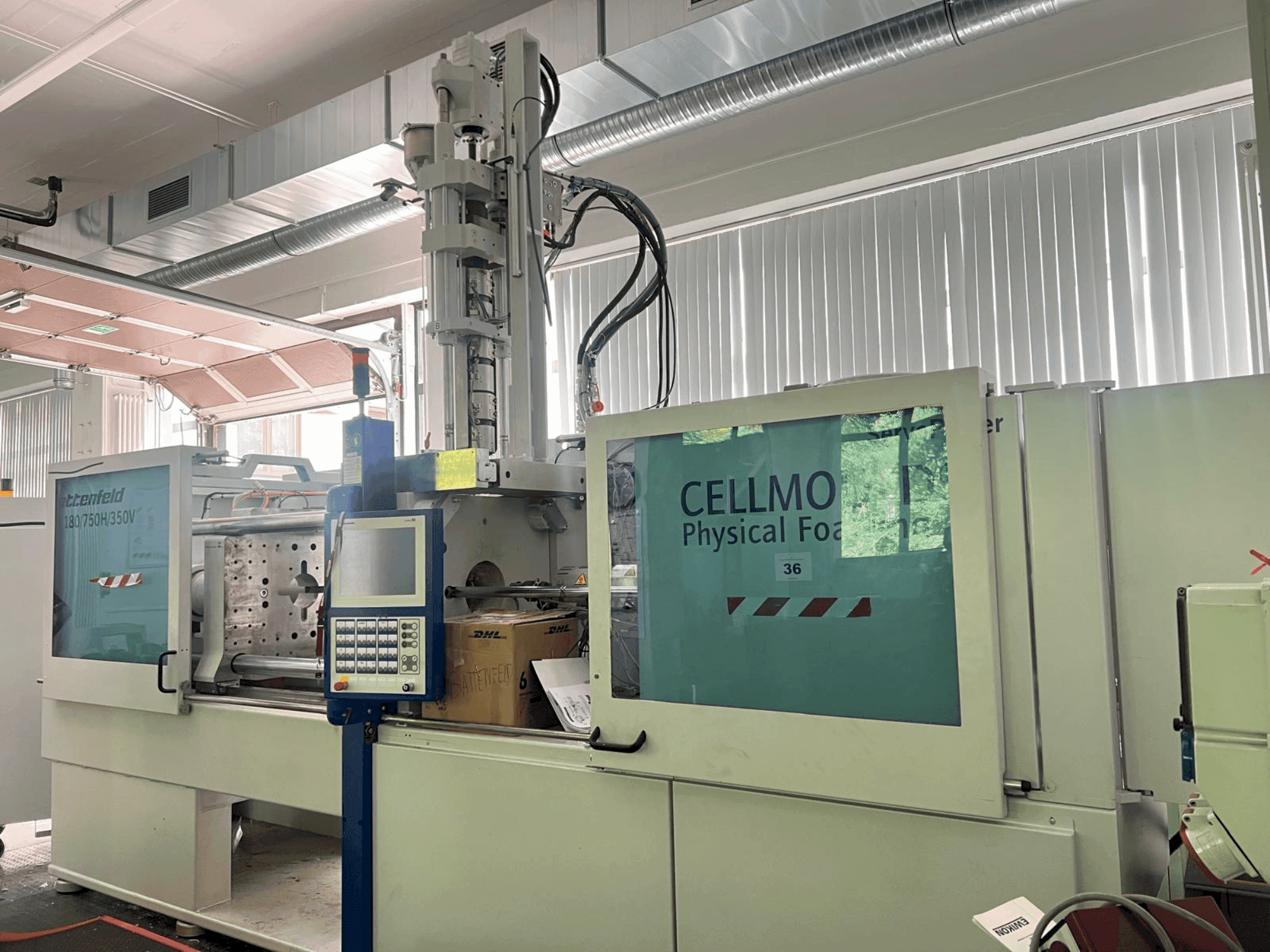

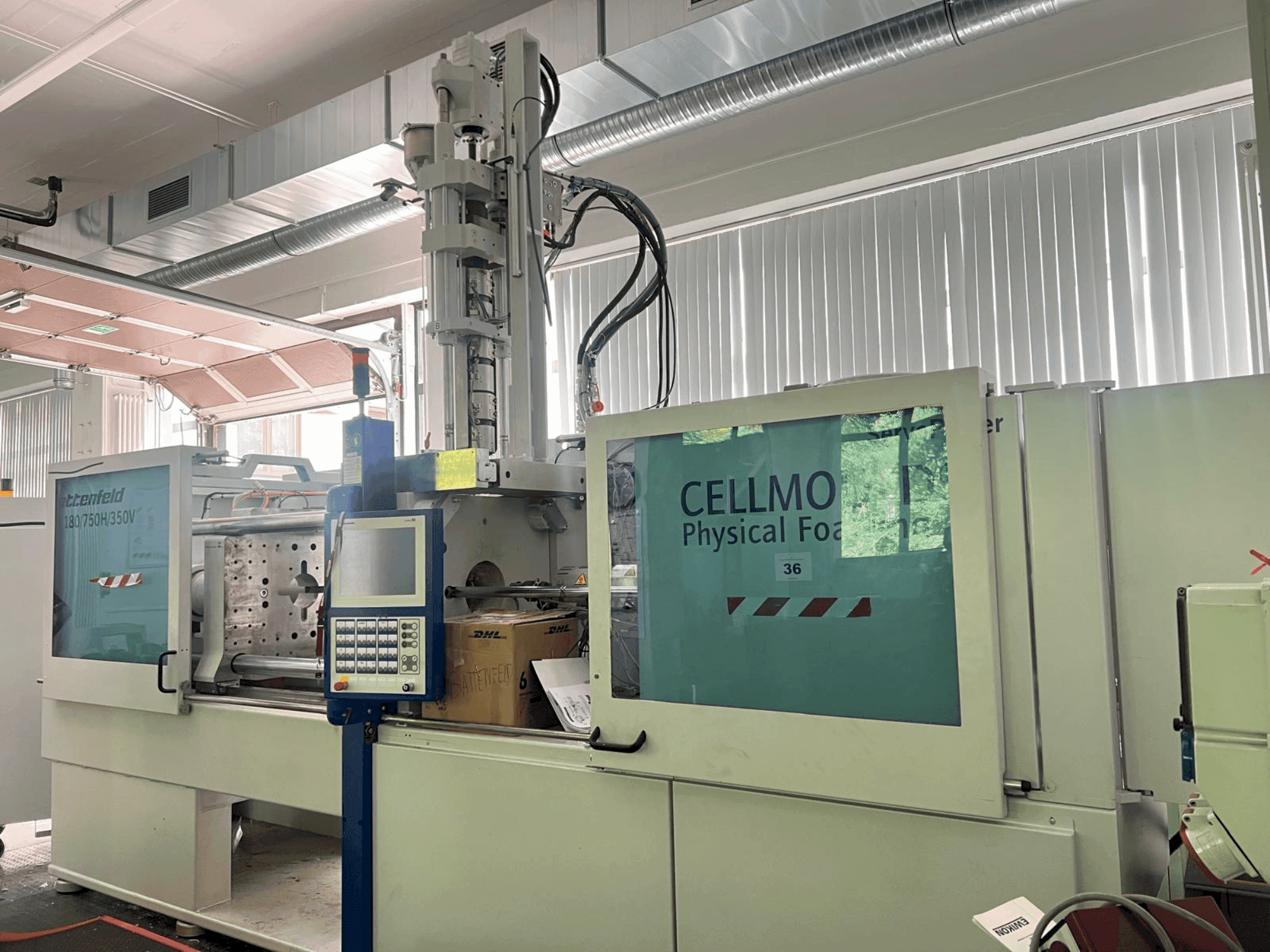

WITTMANN - Battenfeld HM 180/750H/350VDE-INJ-WIT-2016-00002

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used WITTMANN Battenfeld HM 180/750H/350V For Sale

This WITTMANN Battenfeld HM 180/750H/350V was manufactured in 2016. It features a clamping force of 180 tons and a screw diameter range of 40-50 mm. Notable for its multi-component capability, it integrates horizontal and vertical injection units with a rotary table for 2K molding. The UNILOG B6 control system offers an intuitive touchscreen interface. Consider the opportunity to buy this WITTMANN Battenfeld HM 180/750H/350V hydraulic injection moulding machine. Contact us for more information about this machine.

Overview

- brand: WITTMANN

- year: 2016

- MODEL: Battenfeld HM 180/750H/350V

- production hours: 5600

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - WITTMANN Battenfeld HM 180/750H/350V

Dimensions

- Machine Depth: 2800 mm

- Machine Height: 3900 mm

- Machine Weight: 8200 kg

Technical Specification

- Screw Diameter: 40 mm

Additional Information

Additional equipment

- Foaming Unit – Battenfeld “Einschäumungseinheit” for physical foaming (MuCell-like)

- Handling System – Equipped with robot interface; compatible with Wittmann W818/W828

- Conveyor Belt – 1400 mm × 400 mm

- Rotary Table – Integrated, servo-driven, for 2K molding with vertical injection unit

- Control Panel – UNILOG B6 touchscreen with periphery and MES interface capability

- Temperature Unit – 1× GWK Logotherm mold temperature controller

Machine Benefits

Technical Machine Benefits

- Screw stroke: 225 mm

- Theoretical shot volume: 358 cm3

- Spray pressure: 2116 bar

- Max. Screw torque: 998 nm

- Closing force: 1800 kn

- Opening width: 300 mm

- Min. Mold installation height: 325 mm

- Multi-component capability with integrated horizontal and vertical injection units

- Integrated physical foaming for lightweight, rigid part production

- Intuitive unilog b6 control system with touchscreen interface and periphery integration

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing