WILD - Door leaf press linePT-COM-WIL-1998-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used WILD door leaf press line

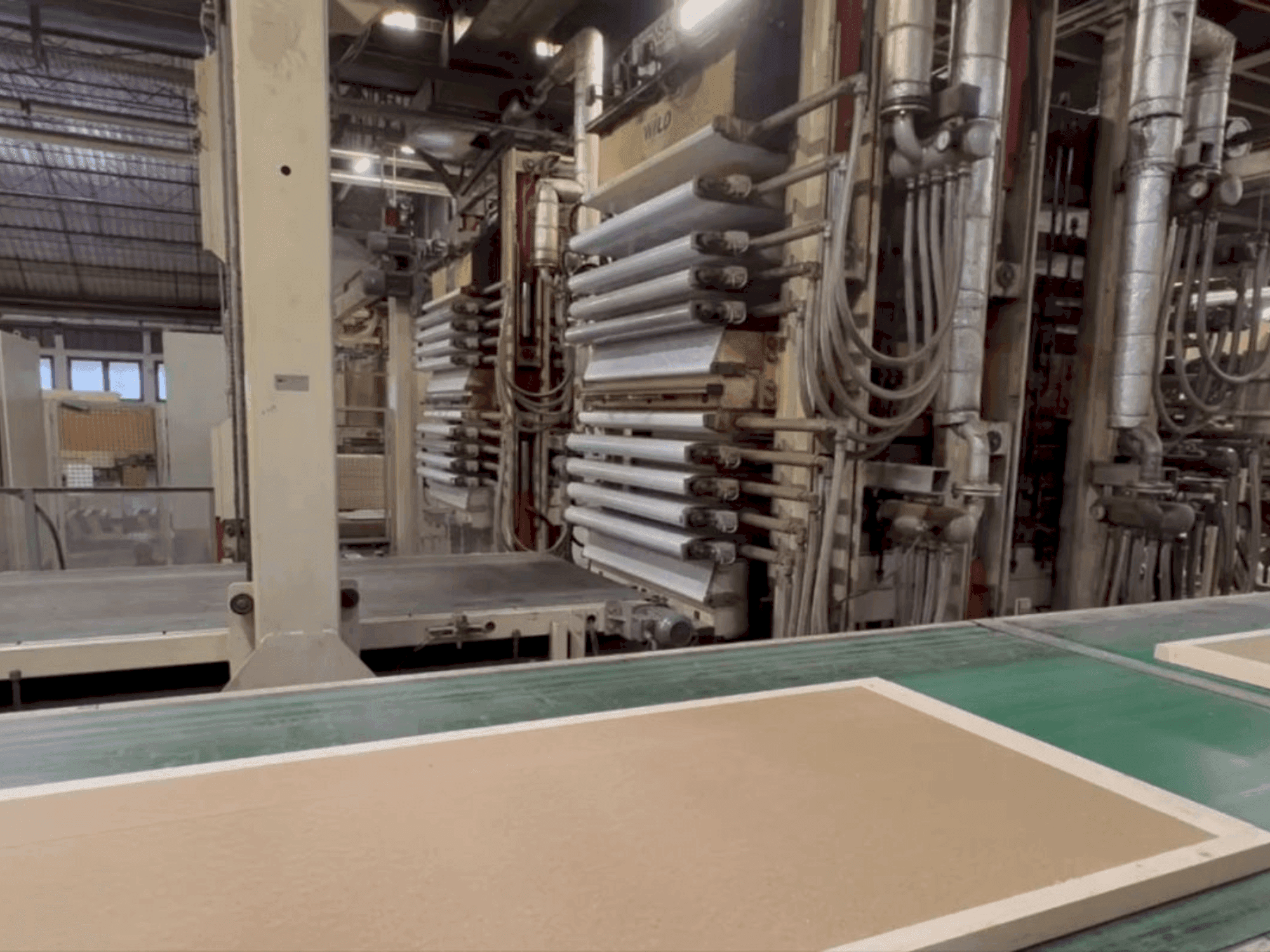

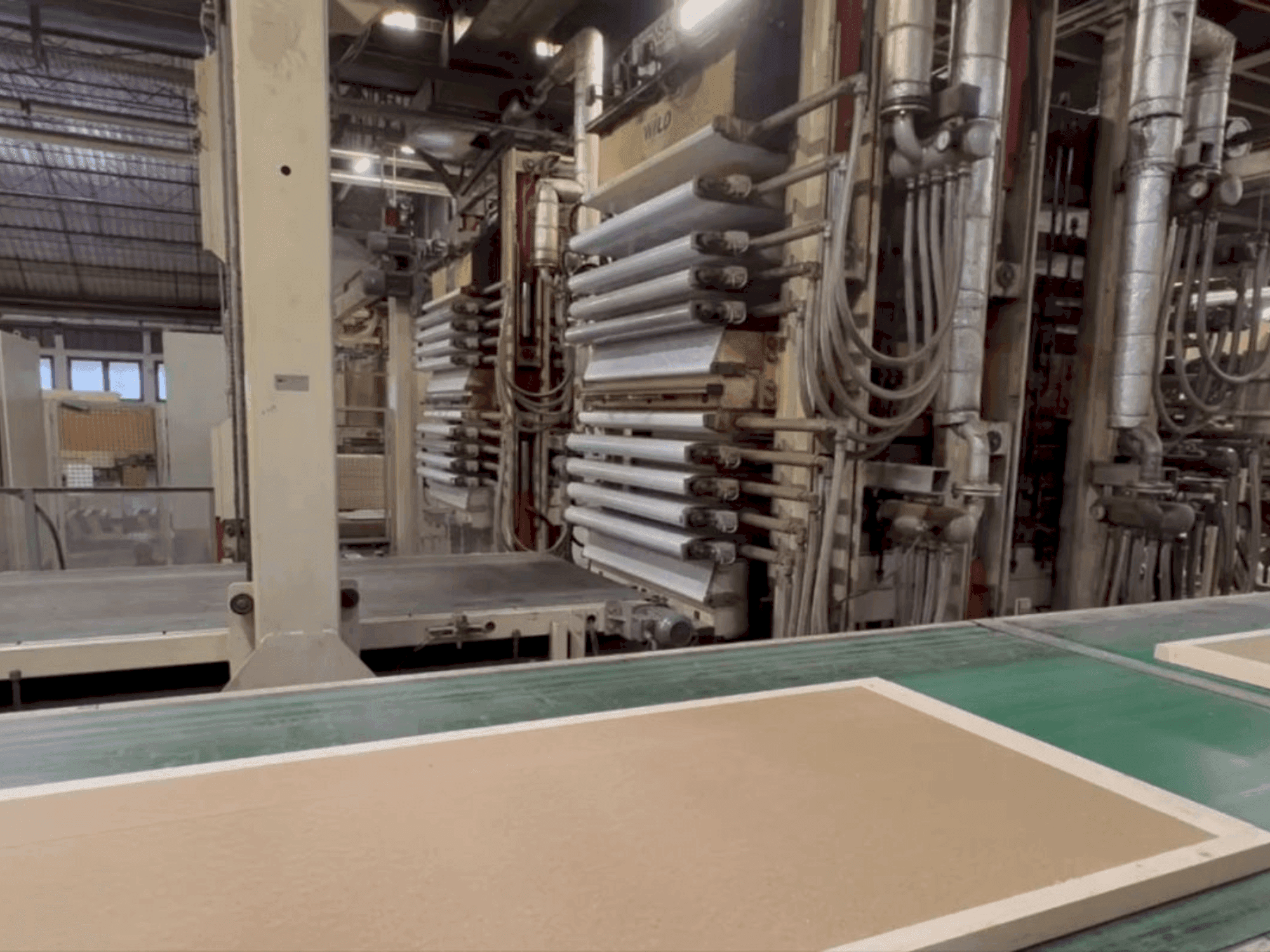

This WILD door leaf press line was manufactured in 1998. It is designed for door production, handling dimensions from 1,800 to 2,300 mm in length, 500 to 1,300 mm in width, and thicknesses of 35, 40, and 44 mm. The line includes areas for gluing, pressing, and handling door panels with advanced feeding and transfer systems. If you are looking to get high-quality door production capabilities consider the WILD door leaf press line we have for sale. Contact us for more information.

Overview

- brand: WILD

- year: 1998

- MODEL: Door leaf press line

- application type: Pressing / Laminating

- Location: Portugal

- machine type: Laminating Press

- Available from: 01/06/2026

Additional Information

Machine Benefits

Technical Machine Benefits

- Dimensions for door production: lengths: 1800 - 2300 mm

- Dimensions for door production: widths: 500 - 1300 mm

- Dimensions for door production: thicknesses: 35 / 40 / 44 mm

Extra Information

Consisting of the following areas: Endless door panel gluing with frame laying station Press line with hard fiberboard loading station First area consists of: Portal feeding Angle transfer with rip and cross cut saw Feeding and supply of longitudinal and cross frame parts from magazines Longitudinal cross-cut station for the longitudinal frame parts Connecting station for the frame parts with the door leaf core, equipped with clamping devices Conveyor belt angle transfer with shuttle transfer of the door leaf cores to the glued hardboard panels Second area consists of: Feeding of the hardboard panels Brush cleaning machine Hardener application machine from below Glue application machine from below Disk roller conveyor Angle transfer for the lower hard fiber board Vacuum turning device for the upper hard fiberboard Automatic loading station for hardboard panels and door leaf cores Two door presses with two x four pressing stations each, set up parallel to each other Both presses are loaded at the infeed with one shuttle loading basket Both presses are unloaded at the outfeed with one shuttle unloading basket Angular transfer to the infeed into a hedgehog buffer Angular transfer at the outlet of the hedgehog buffer and feeding for stacking One-sided vacuum destacking with protective plate placement Note: The technical data and descriptions are transcribed from the original order confirmation. The information is for reference only and is not legally binding.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to WILD Door leaf press line

VMPH 3013

BARTH - Laminating Press

DS 130

ITALPRESSE - Veneer Press

HRB-1450F

HRB - Laminating Press

BTF 1628

BURKLE - Laminating Press

300-K-D0

OTT - Veneer Press

HVP Typ 4

FORMAT4 - Veneer Press

FFAII 1300

BURKLE - Veneer Press

ORMA NPC/DIGIT 6/95 30/13 AS-BO

ORMA - Veneer Press

PROFIPRESS L2500

DIMTER - Laminating Press

MULTIMAT

Columbus - Laminating Press

PFR-CCL

CMB - Veneer Press

XL/6 30-13 PM BO

ITALPRESSE - Veneer Press