Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

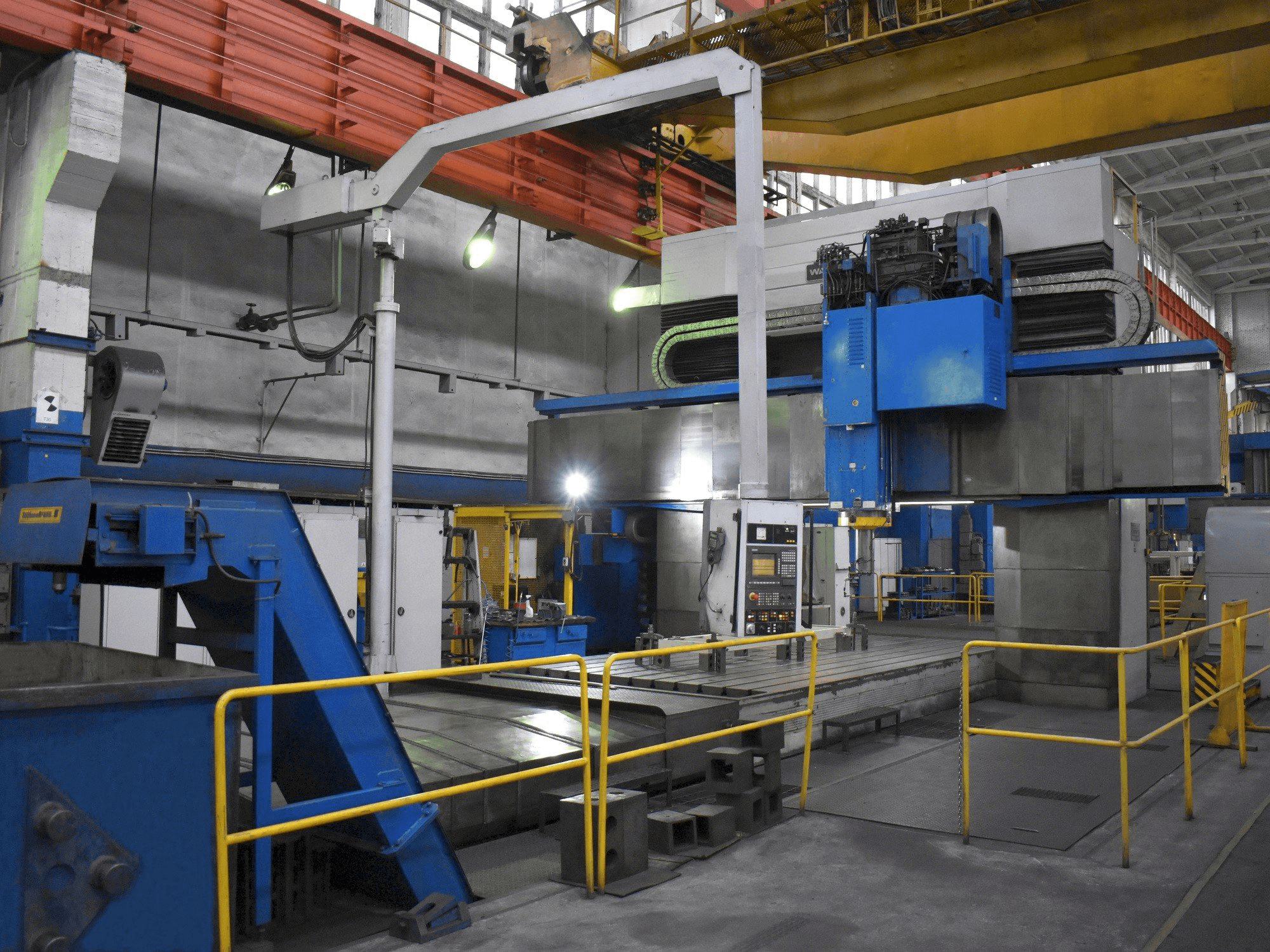

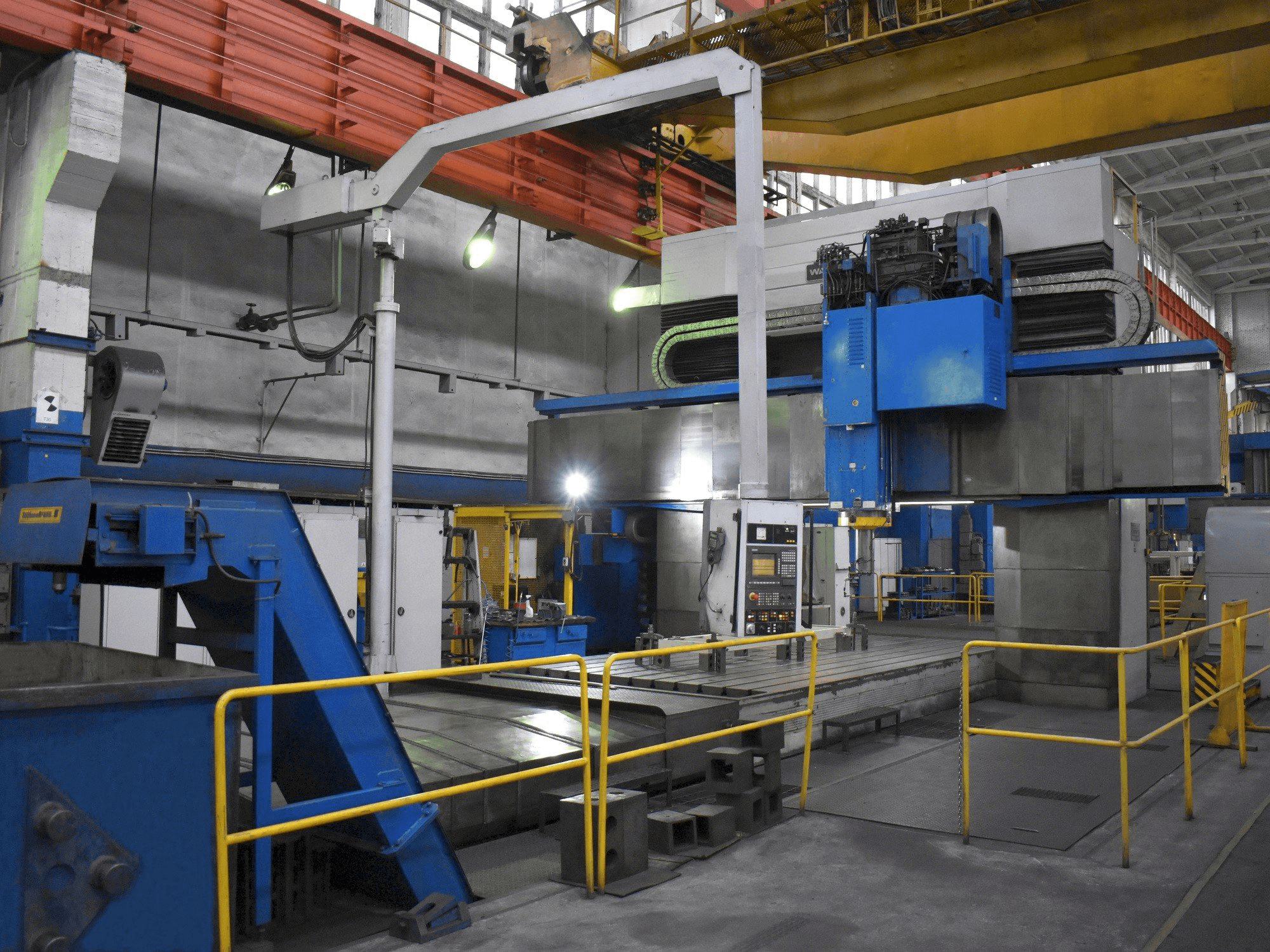

WALDRICH COBURG - 17S 10FP 300 NCPL-MIL-WAL-1989-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- WALDRICH COBURG 17S 10FP 300 NC Gantry Milling Machine

This WALDRICH COBURG 17S 10FP 300 NC Gantry Milling Machine was built in the year 1989 and fully renewed in 2009. It is equipped with a Siemens Sinumerik control unit. The machine has a spindle speed range of 1st gear stage 5 - 2000 rpm, 2nd gear stage 5 - 240 rpm, 3rd gear stage 10 - 480 rpm, and a 4th gear stage of 50 - 2000 rpm.

Overview

- brand: WALDRICH COBURG

- year: 1989

- MODEL: 17S 10FP 300 NC

- application type: Milling

- Location: Poland

- machine type: Gantry Milling Machine

- control unit brand: SIEMENS

Technical Information - WALDRICH COBURG 17S 10FP 300 NC

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik

Dimensions

- Machine Depth: 17100 mm

- Machine Height: 6760 mm

- Machine Weight: 210800 kg

- Table Load: 60000 kg

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Automatic tool changing device:

- 1 chain magazine on the left side of the machine, iso 50 and iso 60 tool holder slots

- Distance between tool holder slots: 165 mm

- Double gripper jaws for permissible

- Permissible tool length 600 mm

- Permissible tool diameter 500 mm

- Tool shank iso 50 (collet)

- Tool shank iso 60 (collet)

- Tool feed to the main spindle, sockets and angle attachments

- Tool change is carried out on the left stand

Technical Machine Benefits

- Height of table above floor: 500 mm

- Width of table: 3000 mm

- Length of fixed single table: 6000 mm

- Number of t-slots: 15, t-slot distance: 250 mm, t-slot width 28h8 mm

- Distance-between, stands = milling width: 3300 mm

- Maximum distance between the table and the end of the spindle when the spindle sled is retracted: 2500 mm

- Ranges, travel: table: 6700 mm, cross beam vertically: 2000 mm, milling slide spindle horizontally: 1000 mm

- Spindle diameter in the front bearing: 170 mm, max. Power of main drive motor 75 kw

- Spindle speed range: 1st gear stage 5 - 2000 rpm, 2nd gear stage 5 - 240 rpm, 3rd gear stage 10 - 480 rpm, 4th gear stage: 50 - 2000 rpm

- Tool holder iso 60, automatic tool clamping with collet

Extra Information

fully renewed in 2009. The machine is in very good working condition, ready for tests. Full documentation available.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing