Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

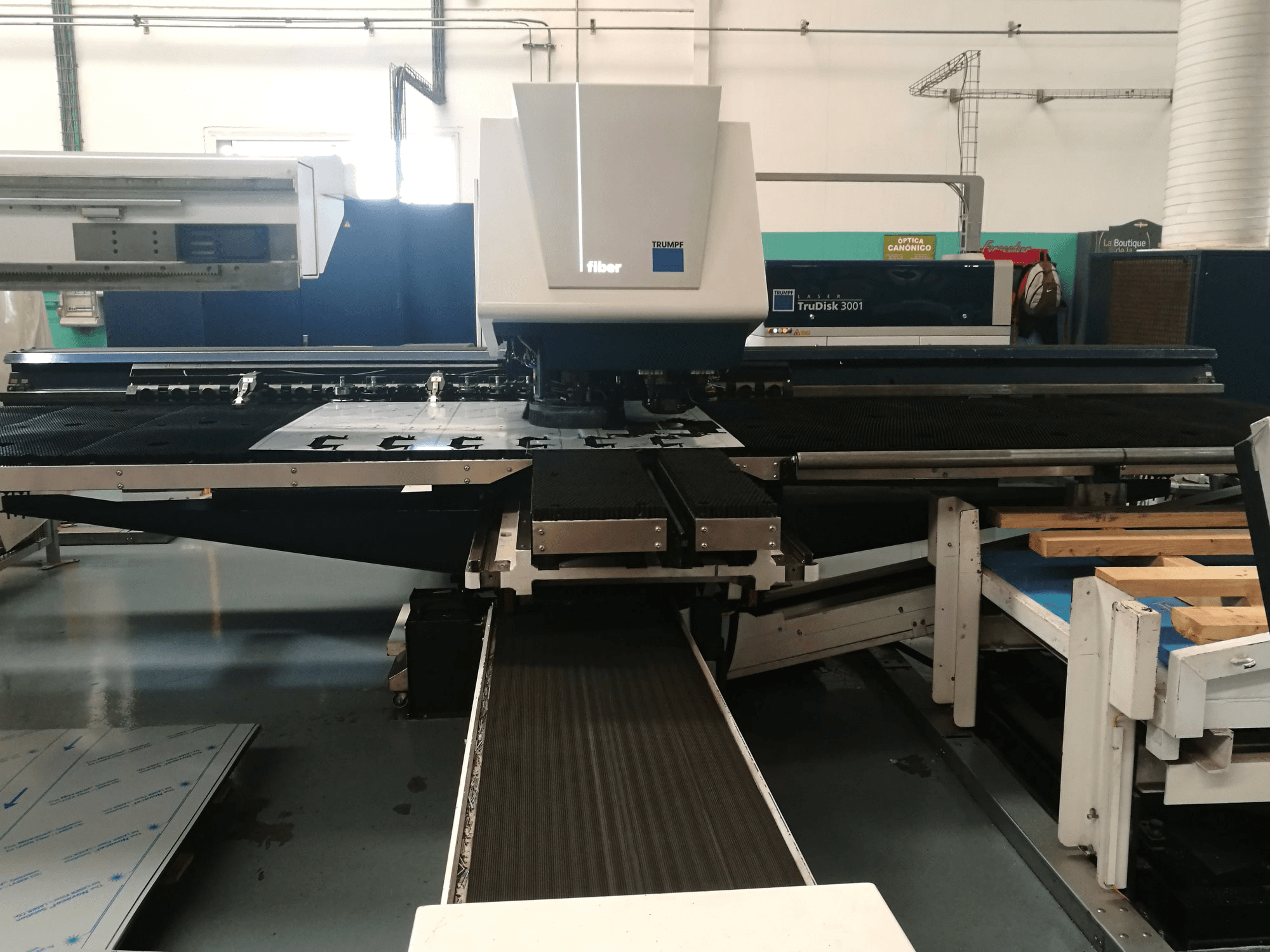

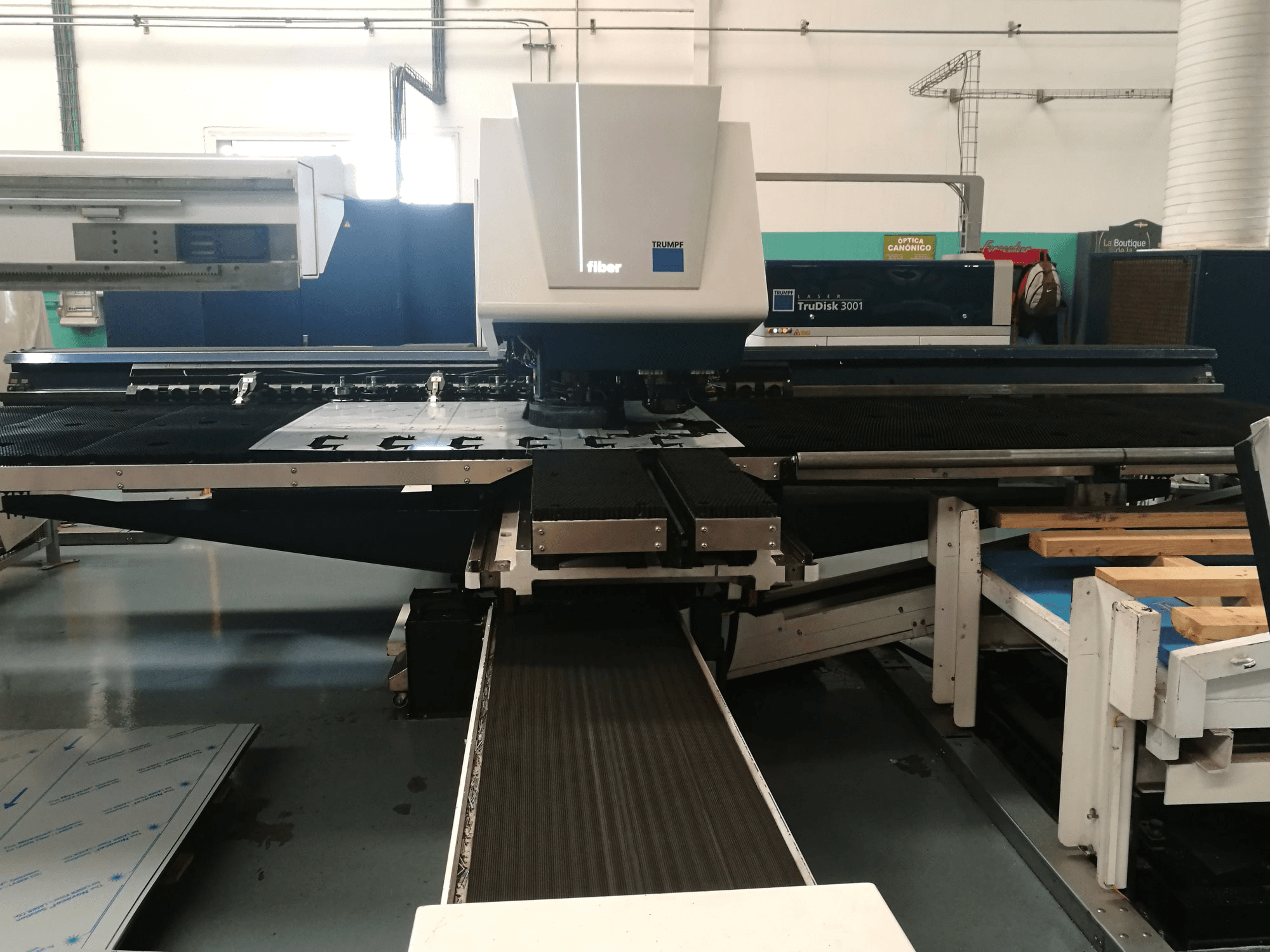

TRUMPF - TruMatic 3000 fiber (K04)ES-LAS-TRU-2011-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- Trumpf TruMatic 3000 fiber (K04) Laser Punch Combination Machine

This Trumpf TruMatic 3000 fiber (K04) Laser Punch Combination Machine was manufactured in 2011 and has a working record of 34000 production hours. Equipped with a SIEMENS Control unit, this machine is in perfect conditions due to frequent Trumpf maintenance and includes a very wide range of complementary equipment like a Trumpf SheetMaser and a Trumpf GripMaster. Furthermore, this machine comes with the following additional equipment included in the delivery: MultiTool function, MultiBend function, Thread shaped function, Fast marking / grooving function, Function roller technology and deburring, Additional clamping claw, Repositioning cylinder with moving parts in height, Small parts sensor for ramp evacuation, Mounting on mattress, Chip conveyor with folding tank, Deformed sheet metal detection, Teleservice function via internet and modem, Off / Load parallel to the main time, Sheet separation system including positioning help for medium format (2500 x 1250), Suction cup frame, Disp. Load control, SortMaster Pallet (6 transversal Pallets x = 1200 mm, y = 800 mm), Double trolley load incl. connection with warehouse, 18 RTC cassettes incl. Matrix plate, QuickSet, Conveyor belt parts, TruTops Punch License.

Overview

- brand: TRUMPF

- year: 2011

- MODEL: TruMatic 3000 fiber (K04)

- production hours: 34000

- application type: Cutting

- Location: Spain

- machine type: Fiber Laser Cutting Machine

- control unit brand: SIEMENS

Technical Information - TRUMPF TruMatic 3000 fiber (K04)

Control Unit

- Control Brand: SIEMENS

Movement

- X-axis Travel: 2500 mm

- Y-axis Travel: 1250 mm

Technical Specification

- Laser Power: 3 kW

Additional Information

Additional equipment

- MultiTool function

- MultiBend function

- Thread shaped function

- Fast marking / grooving function

- Function roller technology and deburring

- Additional clamping claw

- Repositioning cylinder with moving parts in height

- Small parts sensor for ramp evacuation

- Mounting on mattress

- Chip conveyor with folding tank

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing