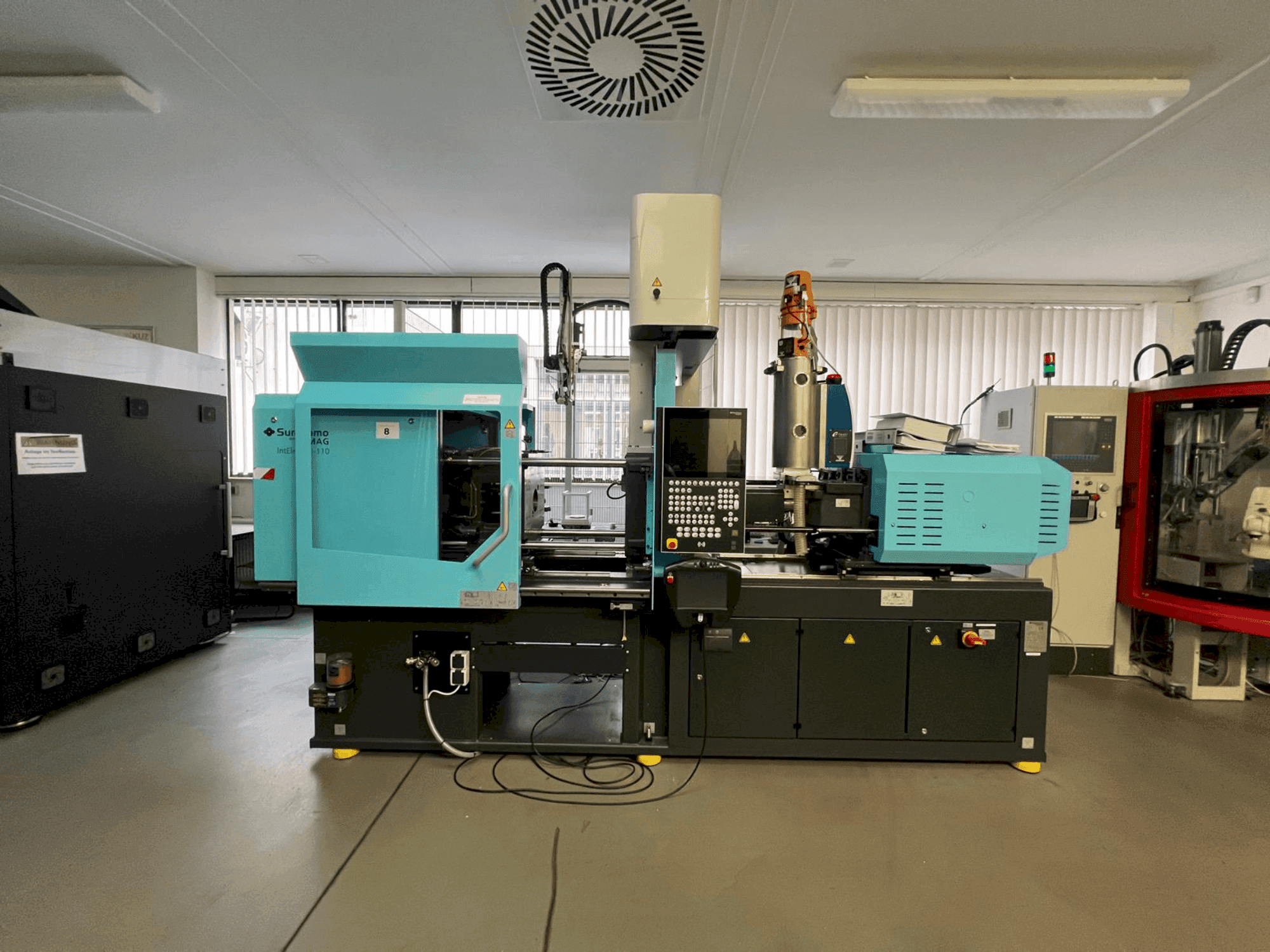

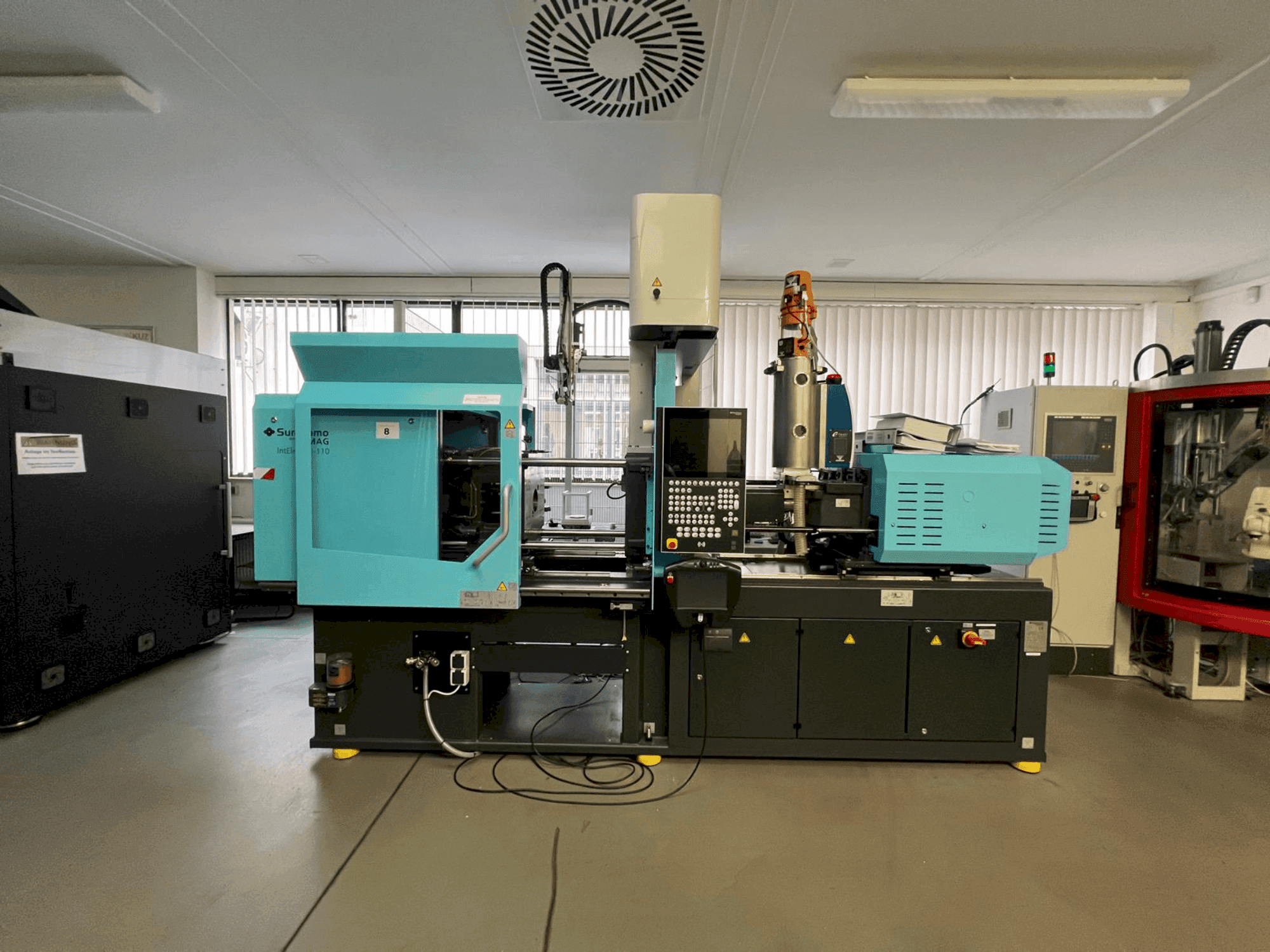

SUMITOMO SHI DEMAG - Intelect 2 50/370-110DE-INJ-SUM-2020-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used SUMITOMO SHI DEMAG Intelect 2 50/370-110 For Sale

This SUMITOMO SHI DEMAG Intelect 2 50/370-110 was manufactured in 2020. It features a fully electric direct-drive system, NC5+ control for enhanced energy efficiency, and precise injection dynamics. Includes a granule dryer, industrial robot, conveyor belt, and temperature units. Ideal for high-quality injection moulding processes. Contact us for more information about this machine.

Overview

- brand: SUMITOMO SHI DEMAG

- year: 2020

- MODEL: Intelect 2 50/370-110

- production hours: 8000

- application type: Injection Moulding

- Location: Germany

- machine type: Electrical Injection Moulding Machine

Technical Information - SUMITOMO SHI DEMAG Intelect 2 50/370-110

Dimensions

- Machine Depth: 4308 mm

- Machine Height: 1779 mm

- Machine Weight: 4200 kg

Technical Specification

- Clamping Force: 500 kN

- Max. Shot Weight: 46 g

- Screw Diameter: 25 mm

Additional Information

Additional equipment

- Granule Dryer

- Handling System

- Conveyor Belt - 1400 mm x 400 mm

- Precision Scale

- Temperature Units - 2x HB‑Therm

Machine Benefits

Technical Machine Benefits

- Exceptional energy efficiency

- Enhanced platen rigidity and mold safety

- Fully electric direct-drive system

- Ultra-precise direct-drive motors with 0. 1 ms response time

- Displacement: 52 cm³

- Spray pressure: 2180 bar

- Tool clamping platens: 520 x 570 mm

Extra Information

Control Unit Advanced control system with NC5+ Automatic mold height and clamping force adjustment Energy-saving routines

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing