Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

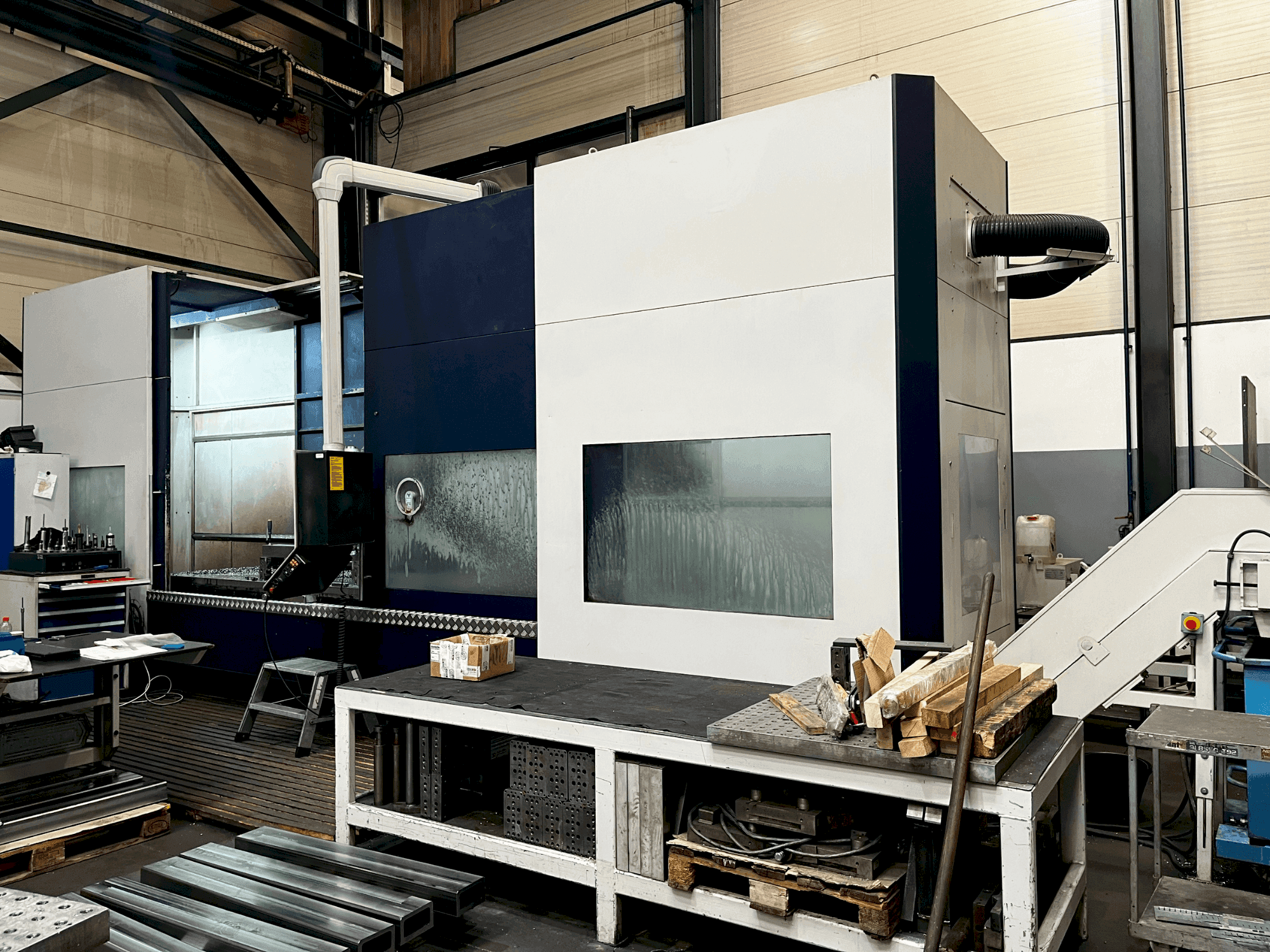

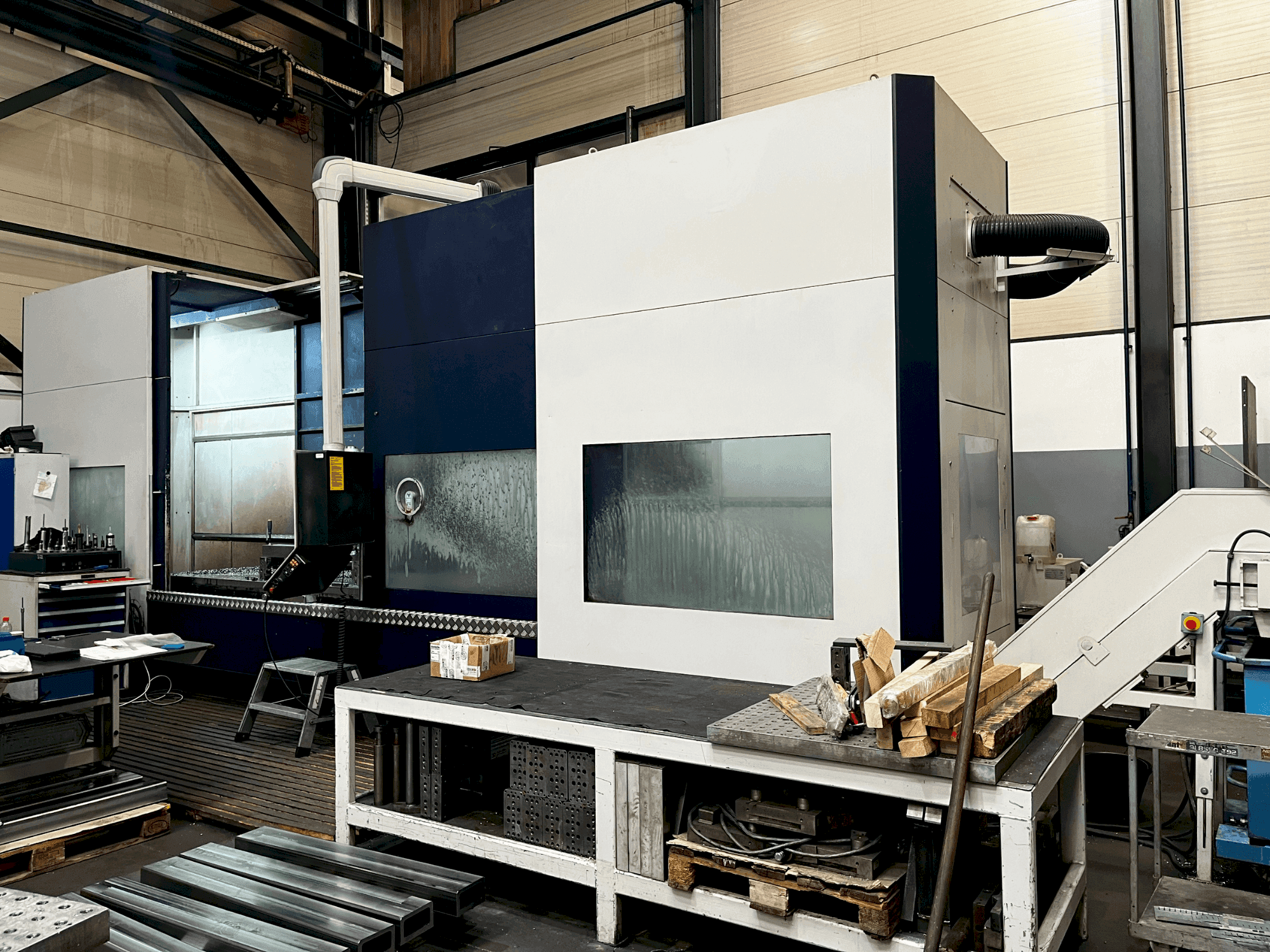

Soraluce - TA-35AHR-MIL-SOR-2015-00002

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- This SORALUCE TA-35A (2015) Milling machine

This SORALUCE TA-35A Milling machine was manufactured in 2015 in Spain. It is equipped with a HEIDENHAIN iTNC 530 HSCI (3 axes + spindle) Rotatable remote unit control pendant with joint. Includes a 19" flat screen, metallic keyboard with integrated mouse, and USB interface at the control panel. Processor speed 0.5 ms included too. Interpolation turning with HEIDENHAIN iTNC 530 consisting of CAM system, HEIDENHAIN post-processor, software adaptation C-axis. The machine has Portable electronic handwheel HEIDENHAIN HR 410 with 3 m spiral cable. Dispose of an automatic indexing milling head with 2.5° x 2.5° division and speeds up to 4000 min-1, 28 kW, 479 Nm, including air cooling/oil mist lubrication, tool clamping force 20,000 N, tool holder ISO 50 - DIN 69871 A (H200), not required when selecting milling head H210. Includes a complete splash guard enclosure with a height of 2,600 mm. Consisting of two front doors and one rear door for operating the machine from the front and rear. All doors and walls are equipped with a total of 7 windows. The Hydraulic weight is compensated by a directly acting on the vertical slide. Contains a Machine table with 5 x T-slots 22 H12 (6 x T-slots for table width 1000 mm) and one reference slot 22 H8, T-slot spacing 140 mm.

Overview

- brand: Soraluce

- year: 2015

- MODEL: TA-35A

- application type: Milling

- Location: Croatia

- machine type: Bed Type Milling Machine

- control unit brand: HEIDENHAIN

Technical Information - Soraluce TA-35A

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC 530 HSCI

Dimensions

- Table Length: 2700 mm

- Table Width: 1000 mm

Movement

- Number of Axes: 3

- X-axis Travel: 3500 mm

- Y-axis Travel: 1250 mm

- Z-axis Travel: 1200 mm

Technical Specification

- Spindle Power: 28 kW

- Spindle Speed: 4000 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Hydraulic weight compensation directly acting on the vertical slide.

- Complete splash guard enclosure with a height of 2,600 mm. Consisting of two front doors and one rear door for operating the machine from the front and rear. All doors and walls are equipped with a total of 7 windows.

- Spindle orientation and thread cutting without compensating chuck.

- Heidenhain ac drive motors in all axes with digital drive technology.

- Ina linear roller guide system rue45-e-l in all axes // automatic centralized lubrication with pressure and time monitoring for all axis and motion components // ball screw drives (it5) in all axes // direct linear measuring system by heidenhain in all axes.

- Telescopic covers for the guides of the x-axis.

- Electrical equipment by siemens.

- Hydraulic system by vickers.

- Workspace lighting (as per ossberger).

- Painting ral 5011 (steel blue), ral 7035 (light gray)

Technical Machine Benefits

- T-slots 6 x 22 h12 // reference slot 1 x 22 // h8 t-slot spacing 140 mm

- Tool holder (option) iso 50, din 69871 ad

- Feed range: x-, y-, z-axis 10 - 10000 mm/min // max. Feed speed: x-, y-, z-axis 25000 mm/min // max. Feed force: x-, y-, z-axis 10000 n // average acceleration 2 m/s2

- Control heidenhain itnc 530 hsci (3 axes + spindle), including 19" flat screen, metallic keyboard with integrated mouse, and usb interface at the control panel. Processor speed 0. 5 ms including heidenhain smart. Nc // rotatable control pendant with join // torque 479 nm

- Interpolation turning with heidenhain itnc 530 consisting of cam system, heidenhain post-processor, software adaptation c-axis (spindle)

- Portable electronic handwheel heidenhain hr 410 with 3 m spiral cable

- Automatically indexing milling head with 2. 5° x 2. 5° division and speeds up to 4000 min-1, 28 kw, 479 nm, including air cooling/oil mist lubrication, tool clamping force 20,000 n, tool holder iso 50 - din 69871 a (h200), not required when selecting milling head h210.

- Cooling lubricant system external cooling (kv 1 / standard) with 250 l tank volume, delivery pressure 5 bar, delivery rate 50 l/min, chamber filter system with micro ventilator and oil belt skimmer with integrated timers, outlet at the milling head via shower ring (d9)

- Complete set of fixators (short anchor screws).

- Teleservice (tel10): remote diagnosis via remote control software (internet) or via vpn software/router (internet).

Extra Information

2 sets of documentation (1 x paper and 1 x CD-Rom) // 3D model of the machine in .step or .iges format.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing