Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

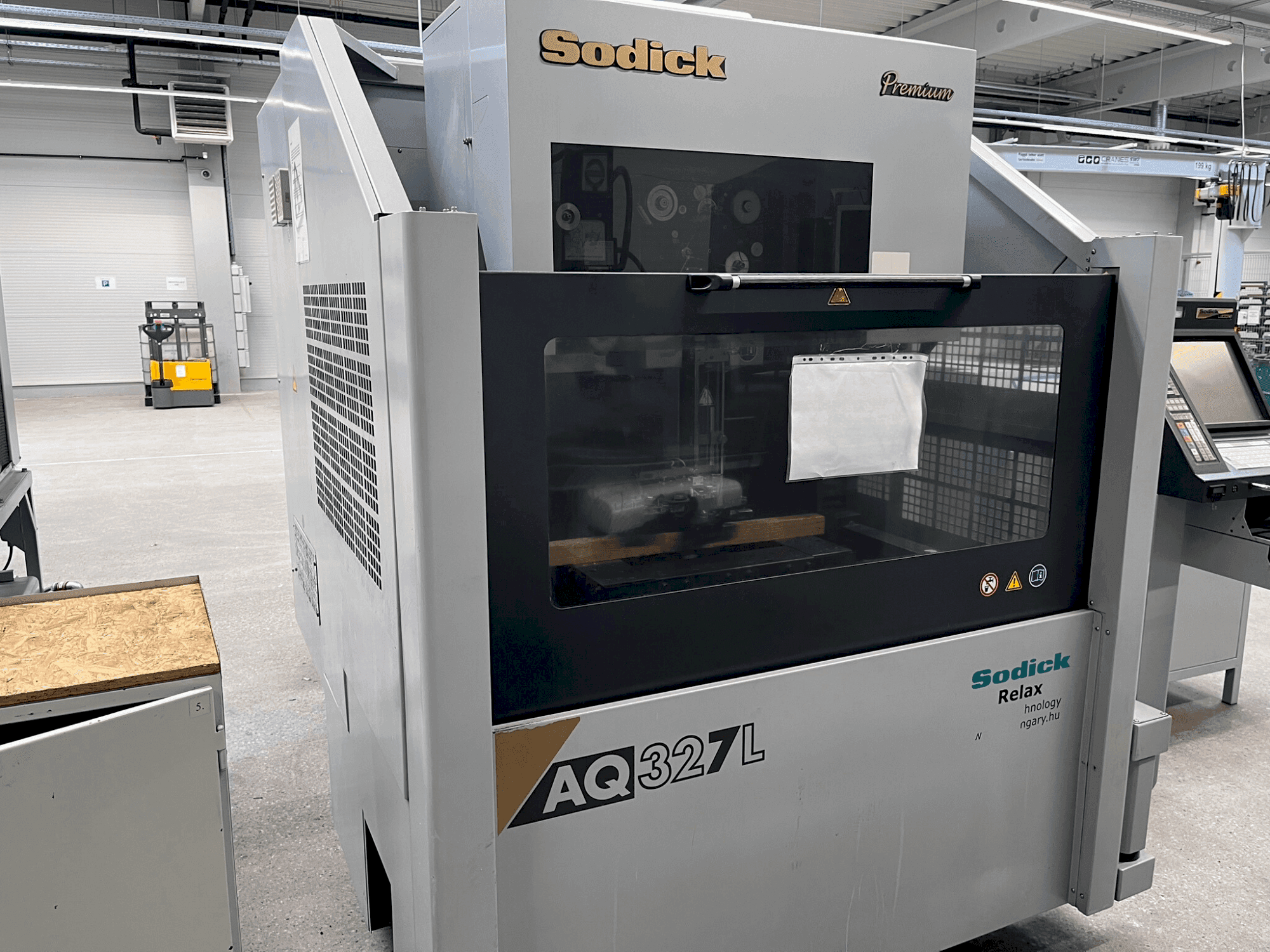

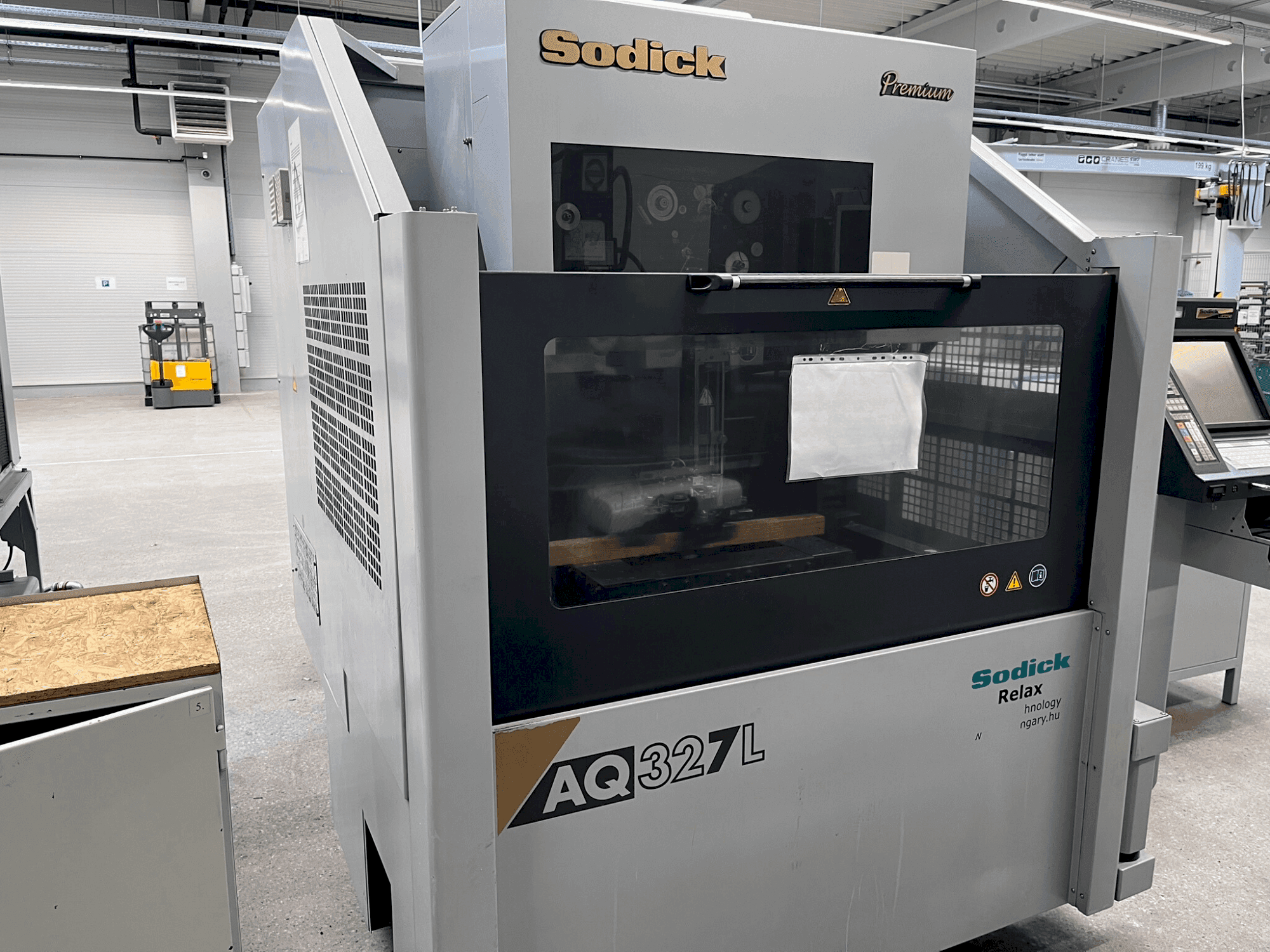

Sodick - AQ327LHU-EDM-SOD-2003-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- SODICK AQ327L Wire cut EDM machine

This SODICK AQ327L Wire cut EDM machine was manufactured in 2006. It is equipped with a SODICK LQ33W control and has 3 axes with axis travel (X x Y x Z) 370 x 270 x 250 mm. The machine has a work tank inner size of 820 x 610 mm and operates with a wire diameter of Ø 0.15 - Ø 0.3 mm.

Overview

- brand: Sodick

- year: 2006

- MODEL: AQ327L

- application type: EDM

- Location: Hungary

- machine type: Wire EDM Machine

- control unit brand: SODICK

Technical Information - Sodick AQ327L

Control Unit

- Control Brand: SODICK

- Control Model: LQ33W

Dimensions

- Machine Weight: 3950 kg

Additional Information

Machine Benefits

Technical Machine Benefits

- Work tank size: 850 x 610 mm

- Max. Workpiece dimensions (w x d x h) 570 x 420 x 240 (flushing) mm // 570 x 420 x 230 (submerged) mm

- Max. Workpiece weight: 500 kg

- U axis x v axis travel 120 x120 mm

- Taper angle (workpiece thickness of 100mm) ±25°

- Wire diameter 0. 15~0. 30#1 mm

- Wire feed speed (max) 420 mm/sec

- Wire tension 3~23 n

- Distance from floor to table top 995 mm

- Total power input normal: 10,5 kva

Extra Information

Sodick's pioneering advancements in core technology have propelled them to achieve unparalleled feats in high-speed precision machining, epitomized by their groundbreaking "7 series". Extensive simulations conducted through state-of-the-art 3-D design systems have underscored the advantages of Sodick's innovative design approach, leveraging ceramics for critical machine tool components. Nonetheless, Sodick remains steadfast in its commitment to time-tested methodologies, such as meticulous scraping of all mating surfaces, to optimize the inherent robustness of the machine's foundational structure. The cutting-edge electric discharge control system orchestrates machine tool operations with precision, while the incorporation of linear motors on each axis ensures unparalleled responsiveness.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing