Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

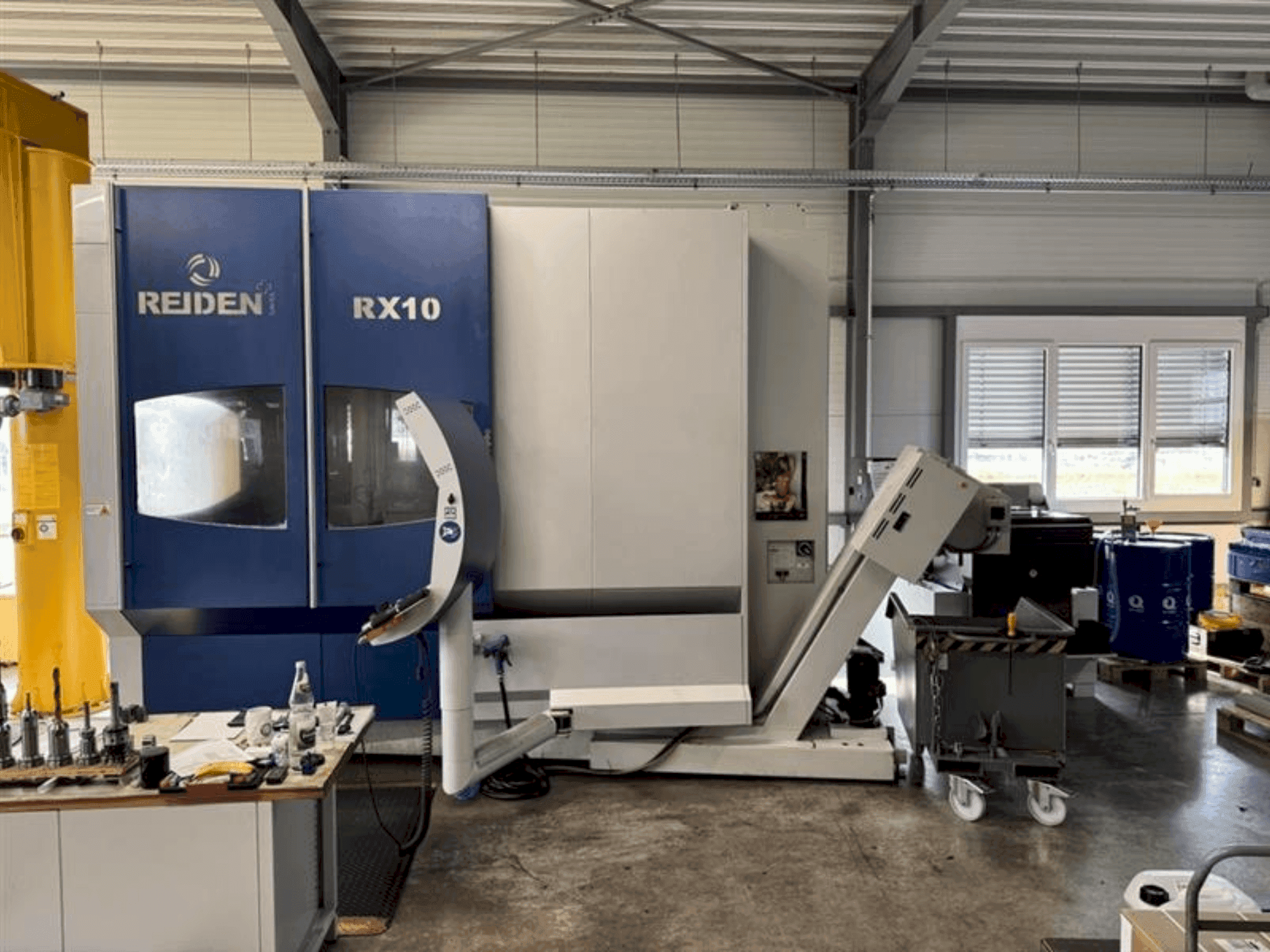

Reiden - RX10 5XDE-OTH-REI-2019-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Reiden RX10 5X Machine Tool For Sale | gindumac.com

This 5-axis Reiden RX10 5X was manufactured in 2019 and features a HEIDENHAIN TNC 640 control system, a swiveling control panel with dual 19" monitors, and a high-speed swivel milling head with a speed of 16,000 min-¹. It includes a rack magazine with 85 tool places and an internal coolant supply at 80 bar. If you are looking to get high-quality milling capabilities, consider the Reiden RX10 5X machine we have for sale. Contact us for more information.

Overview

- brand: Reiden

- year: 2019

- MODEL: RX10 5X

- production hours: 6293

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - Reiden RX10 5X

Control Unit

- Brand: HEIDENHAIN

- Model: iTNC 640

Main drive

- Spindle speed range: 16000 1/MIN

- Spindle motor power: 38 kW

- Number of axis: 5

Movement

- X-AXIS Movement: 1000 mm

- Y-AXIS Movement: 1100 mm

- Z-AXIS Movement: 810 mm

Tools

- Type of tool holder: HSK 63-A

Additional Information

Additional equipment

- Chip Transport: Scraper belt chip conveyor (ejection height: 1100 mm)

- Protective systems: Full-space protective cladding with angled door and quick-access door

- Laminated glass viewing windows

Machine Benefits

Technical Machine Benefits

- Torque: 105 nm (100 % ed), 135 nm (40 % ed), 155 nm (25 % ed)

- Nc rotary table: Ø 1000 × 800 mm with t-slots (18h7 / 100 mm)

- Drive: preloaded screw

- Oscillating circuit: Ø 1350 mm

- Tool changer: rack magazine with 85 places

- 5-fold tool loading station

- Dialog control panel

- Blum tc60 wireless touch probe (incl. Kinematicsopt and calibration ball)

- Trs2 tool breakage detection (for tools from Ø 2 mm)

Extra Information

Measuring Systems: Direct path measuring systems (HEIDENHAIN) with sealing air connection Micro-Epsilon “Spindle Growth System” (thermal spindle compensation) HEIDENHAIN software options: AFC, ACC, DNC option, DXF converter The machine received a complete update last month, with a latest generation milling head featuring electronic temperature monitoring. Media Coolant Supply: Internal coolant supply (80 bar, 20 l/min) with paper band filter and fine filter (40 µm) Air blast through the center of the spindle (selectable via M function) Oil and emulsion mist extraction (1800 m³/h suction power) Control Unit Control: HEIDENHAIN TNC 640 Swiveling control panel with two 19" monitors HEIDENHAIN HR510 handwheel 3 potentiometers (feed rate, rapid traverse, speed) 3-color status light HEIDENHAIN DCM (collision monitoring)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to Reiden RX10 5X

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

VTC-300C

Mazak - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

PICOMAX 55 CNC 2/3

FEHLMANN - Vertical Machining Centre