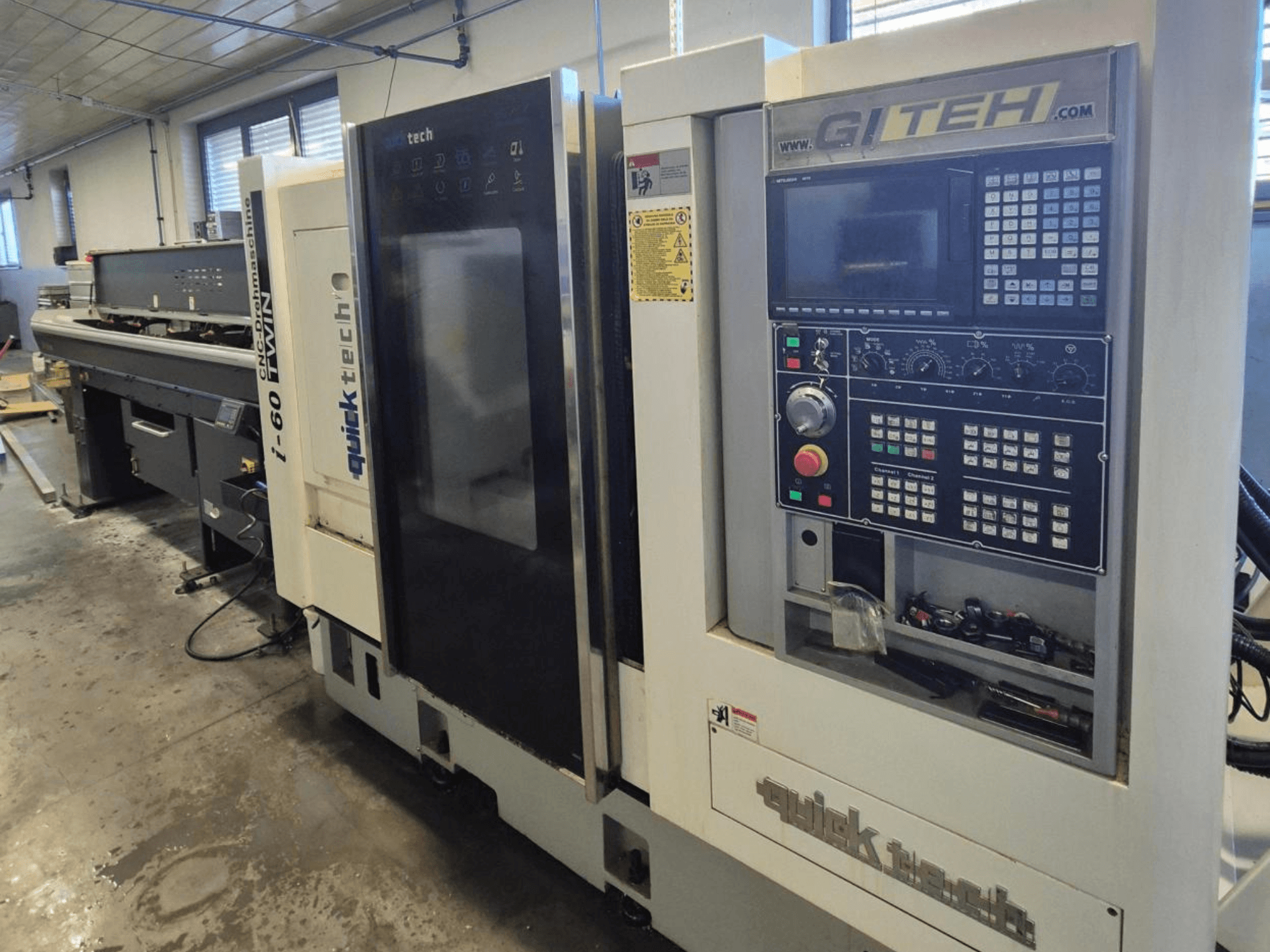

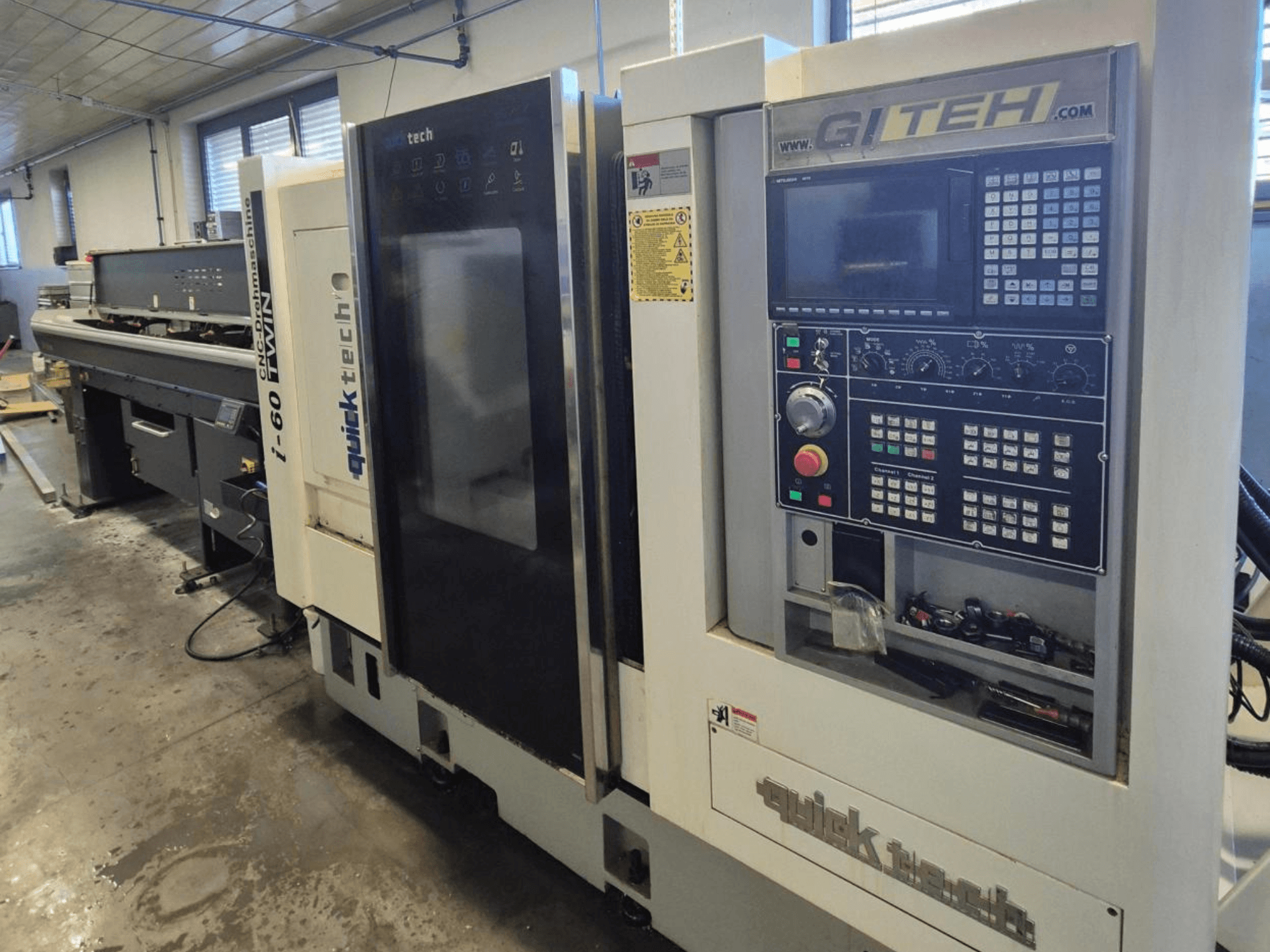

Quick-Tech - i60 twin SI-TUR-QUI-2016-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Quick-Tech i60 twin For Sale | gindumac.com

This 6-axis Quick-Tech i60 twin was manufactured in 2016, featuring a CNC turning center with B-axis and driven tools. It includes a main spindle bore of 60 mm, sub spindle bore of 42 mm, and a maximum turning length of 300 mm. The machine offers 4-axis simultaneous machining, full axis programming, and a Mitsubishi M70 control system. Consider the opportunity to buy this Quick-Tech i60 twin horizontal turning machine. Contact us for more information about this machine.

Overview

- brand: Quick-Tech

- year: 2016

- MODEL: i60 twin

- application type: Turning

- Location: Slovenia

- machine type: Horizontal Turning Machine

- control unit brand: MITSUBISHI

Technical Information - Quick-Tech i60 twin

Control Unit

- Control Brand: MITSUBISHI

- Control Model: M70

Movement

- Number of Axes: 6

Technical Specification

- Counter Spindle: Yes

- Driven Tools: Yes

- Spindle Speed: 4000 RPM

Additional Information

Main spindle bore: 60 mm

Sub spindle bore: 42 mm

Max. turning length: 300 mm

Speeds

Main spindle: 4000 rpm

Sub spindle: 4000 rpm

Driven tools: 4000 rpm

Spindles

Main spindle indexing: 0.001°

Sub spindle indexing: 0.001°

Hydraulic spindle brake (main & sub)

Synchronization of spindle rotation and positioning

Tool stations

Main spindle side: 6 external turning, 5 internal turning

Sub spindle side: 3 external turning, 4 internal turning

Driven tools: 12 stations

Processing capabilities

4-axis simultaneous machining

Full axis programming directly from the control

Air blow function (M-code)

Part ejection detection

Workholding

Main spindle chuck: Ø185 mm

Sub spindle chuck: Ø173 mm

Machine equipment

Machine leveling screws and plates

LED working light

3-color signal tower

Automatic central lubrication system

Coolant tank and coolant level sensor

High-pressure coolant pump 30–40 bar

380V/220V transformer

Basic tool kit

Operator manual, programming manual, electrical diagrams, PLC documentation

Control system: Mitsubishi M70

10.4” color display; MPG handwheel program check

Absolute/incremental programming; ISO programming

Automatic machine power-off function

Thread cutting cycle (G92); rigid tapping

Constant cutting speed (G96/G97)

Production time display & part counter

Jog movement for X, Z, Y, W axes; C1 and C2 contouring for turning/milling

Minimum input increment: 0.001 mm

80 tool geometry & correction positions

Program loading via memory card or USB; network connectivity

Chamfer & radius programming; radius compensation

Absolute motors (no homing required); self-diagnosis functions

Spindle synchronization

Thread cutting with driven tools; thread cutting on sub spindle

Programming help functions; 2D program simulation

PLC editing capability

Gear cutting function included

Driven tool orientation

Additional equipment (not part of the base machine)

Chip conveyor

Bar feeder VITO 56 (3 m)

Finished part conveyor

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing