Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

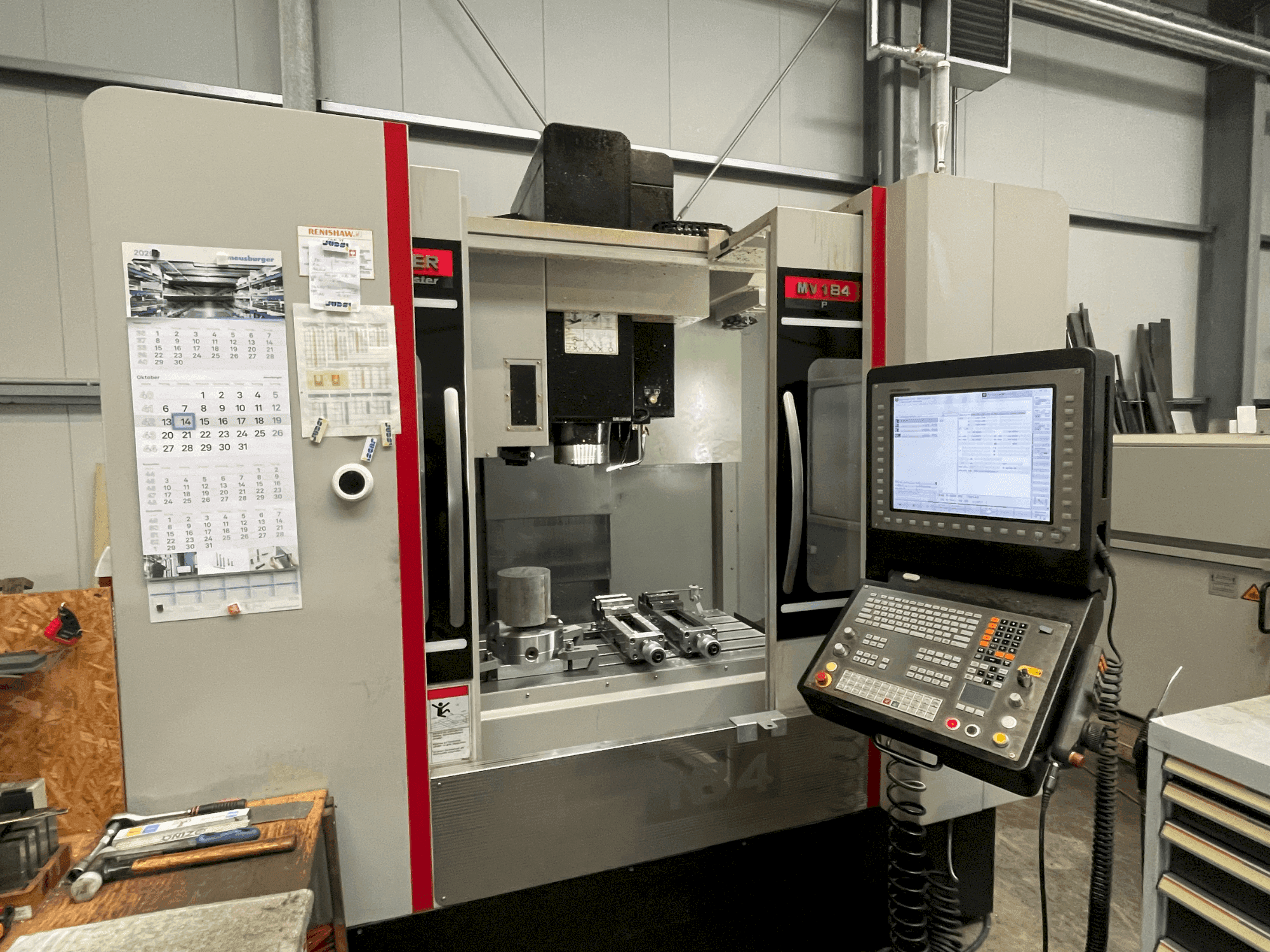

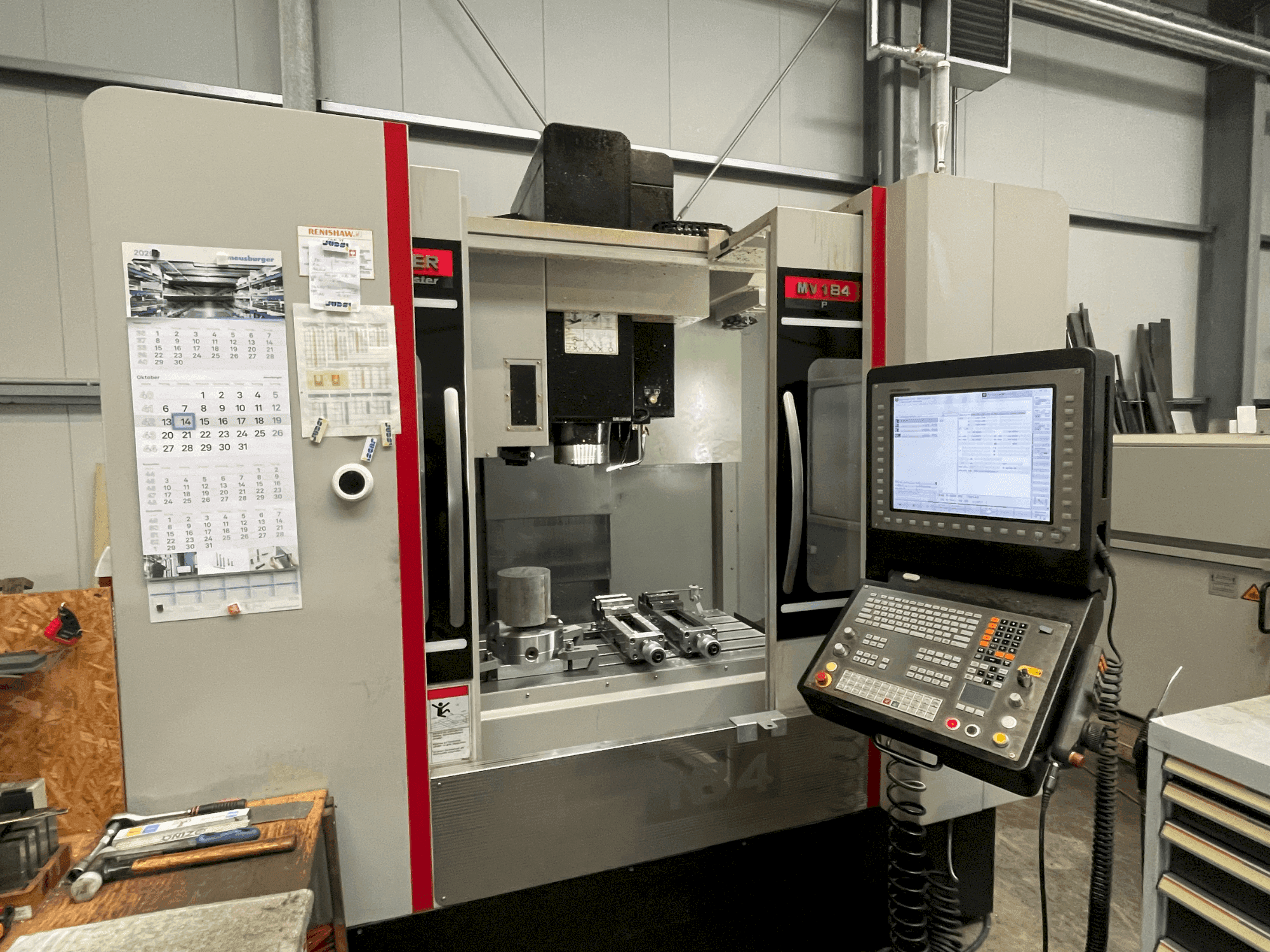

Quaser - MV 184P/12BDE-MIL-QUA-2019-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Quaser MV 184P/12B For Sale | gindumac.com

This 4-axis Quaser MV 184P/12B was manufactured in 2019 and features a Heidenhain TNC640 control, a belt-driven main spindle with SK40 type, and a Lehmann rotary table. It includes a temperature-controlled cooling system, internal coolant supply with filtration, and a drum filter for advanced chip disposal. The machine base is made of heavily ribbed cast iron, ensuring stability and precision. Consider the opportunity to buy this Quaser MV 184P/12B vertical machining centre. Contact us for more information about this machine.

Overview

- brand: Quaser

- year: 2019

- MODEL: MV 184P/12B

- production hours: 17526

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - Quaser MV 184P/12B

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: TNC 640

Movement

- Number of Axes: 4

Additional Information

Screen/operation: Large TFT screen with movable, tiltable and rotatable control panel

Memory: Program storage on SSDR

Hand control: Portable electronic handwheel

Machine body: Computer-optimized, heavy, heavily ribbed cast-iron base

Control cabinet: Control cabinet cooler

Signaling: Three-color signal light

Colors: RAL 7035 Light Gray (machine), RAL 9005 Jet Black (coolant tank, headstock, door)

Main spindle: SK40, belt-driven MB-4.0

Spindle cooling: Temperature-controlled cooling system

Rotary union: Deublin rotary union for belt-driven spindle

Tool changer: Extended tool changer for warm-up tools

Pull stud: Pull stud with bore

Preparation for 4th axis: Cable preparation for 4th axis (Quaser) with Harting connector and mounting frame; preparation of 4th axis for Heidenhain rotary table

Flood cooling: Ring-shaped outlet nozzles on spindle nose, via Grundfos pump

Internal coolant supply (ICS): With Grundfos pump; cartridge filter included

Spindle purge air: Additional blown air through spindle, switchable via M-function (Heidenhain)

Chip handling (basic): Work area chip flushing via Grundfos pump; stainless steel chip chutes in work area

Lubrication: Automatic central lubrication for ball screws; automatic hybrid lubrication for guides and ball screws

Additional equipment

4th axis: Lehmann rotary table (single-spindle)

3-jaw chuck: BFU.520-250ps for rotary table

Rotary table motor: Mavil ERN, plug-in ready (angled Harting connectors)

Advanced filtration and chip evacuation: Drum filter (filtration up to [value not provided]) including scraper belt chip conveyor

Workpiece and tool measurement system:

Infrared receiver for workpiece/tool measurement

Renishaw OMP40-2 measuring probe with optical signal monitoring; includes tool set and operating manual

PS3-1C straight stylus with ceramic shaft and ruby ball (M4 thread)

Renishaw OTS toolsetter with optically modulated transmission, adjustable table mount, carbide stylus disc; includes tool set and quick-start guide

Tool change kit for OTS/RTS: A-5401-4030 change adapter for OTS and A-5401-4032 clamping bar for slots

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing