PEMA - Column & Boom HD 4x4 Twin SAWEE-WEL-PEM-2019-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used PEMA Column & Boom HD 4x4 Twin SAW | Laser Welder

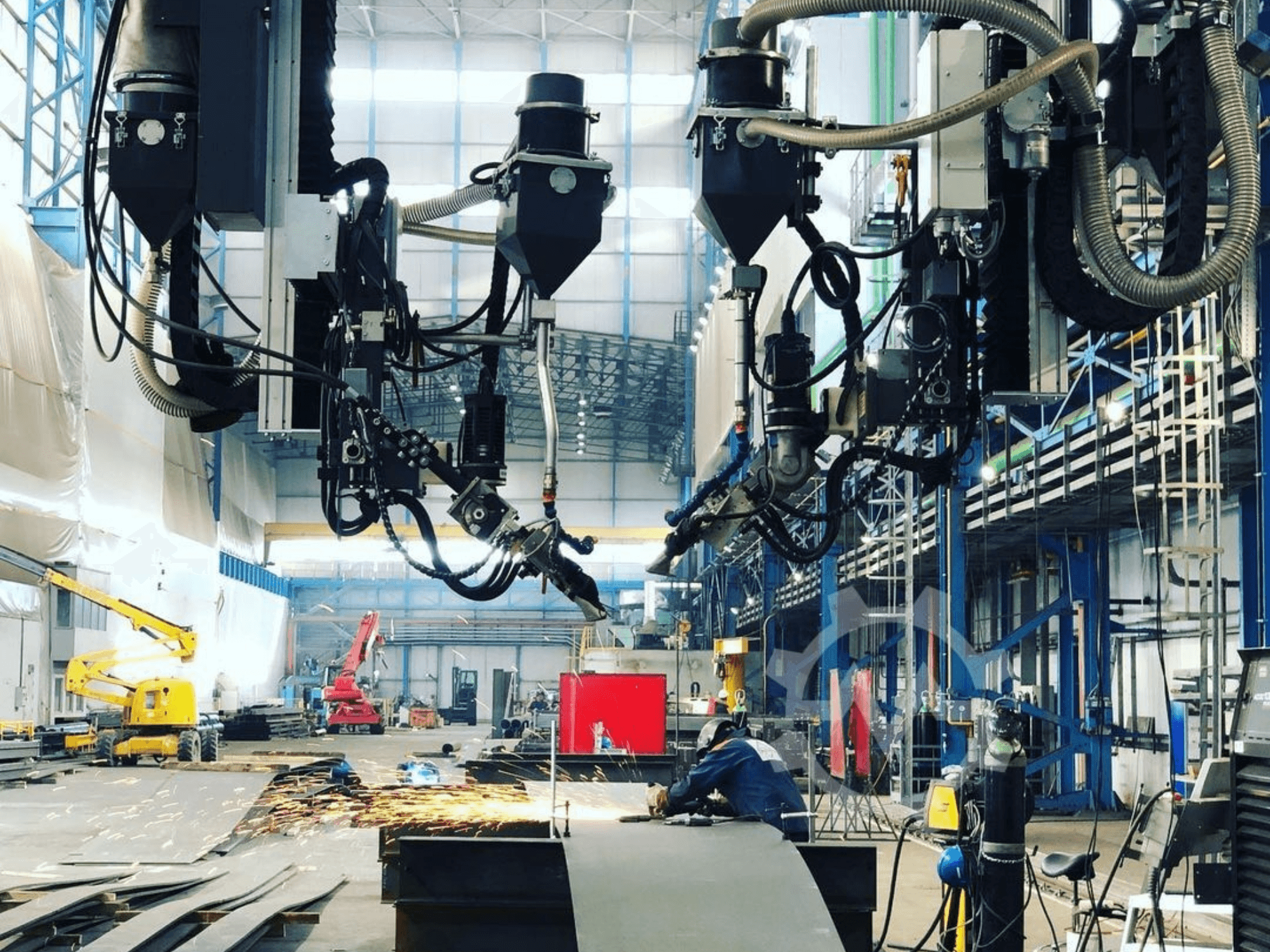

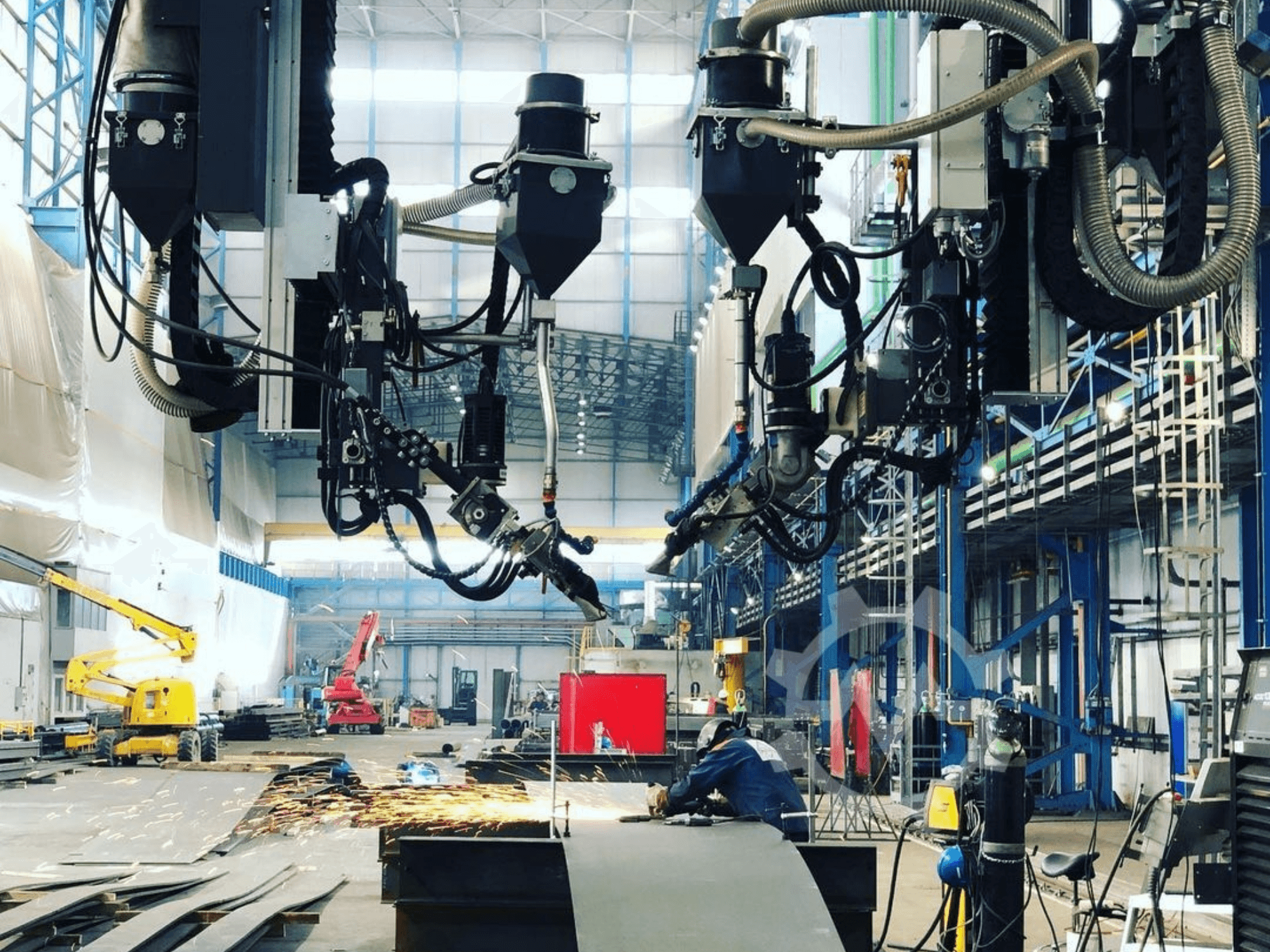

This PEMA Column & Boom HD 4x4 Twin SAW was manufactured in 2019. It features a PEMA control panel with touch screen and WeldControl 100 for precise beam welding. The machine includes twin SAW heads, motorized traveling carriages, and a comprehensive wire feeding system. Ideal for longitudinal-shaped workpieces with a working range of 4m vertically and horizontally. Consider the opportunity to buy this PEMA Column & Boom HD 4x4 Twin SAW laser welding machine. Contact us for more information about this machine.

Overview

- brand: PEMA

- year: 2019

- MODEL: Column & Boom HD 4x4 Twin SAW

- application type: Welding

- Location: Estonia

- machine type: Laser Welding Machine

Additional Information

Status and storage

Dismantled by Pematek Oy in September 2022

Stored in a warm, dry factory, wrapped in plastic

Indoor operation; ambient +5 °C to +40 °C, relative humidity 40%–80%

Machine/system

PEMA Column & Boom Semi-Portal for beam welding (heavy-duty C&B welding manipulator)

Application: Automated submerged arc welding (SAW) of beams and other longitudinal workpieces

Working range: 4 m vertical × 4 m horizontal

Two welding arms with twin SAW heads

Mounted on a motorized rail carriage for welding movement

Control

PEMA control panel with touch screen

Standard control system: PEMA WeldControl 100 (process control included)

Included welding equipment

2 × Lincoln AC/DC 1000 SD Powerwave power sources for SAW

2 × Lincoln MAXsa 29 wire feeders (feed heads)

2 × Ejector-type flux recovery systems integrated in welding arms

2 × Pressurized air flux feeding tanks, 75 L each, heating up to 120 °C

2 × Electro-mechanic joint tracking units

4 × Wire feeding and reel holders (250 kg each) + additional rear reels 4 × 250 kg and 4 × 30 kg

2 × Twin torch assemblies (2 × 2.4 mm)

Wire dimensions supported: Ø 2–4 mm; twin wire Ø 2–2.5 mm

PEMA pneumatic-assisted wire feeding system

Manipulator and rail carriage

Two movable welding carriages with twin SAW heads

Rail carriage with guide roller-supported steel wheels

Rail width (inside-to-inside): 2350 mm

Traveling speed: 200–2500 mm/min

Side support rollers for precise movement

Cable management/chains for column, boom, and slide movement

Column & boom

Total height from rail: approx. 6900 mm

Boom length: approx. 4.5 m

Vertical boom movement: floor up to 2000 mm

Motorized welding carriages with 1000 mm vertical slide

Horizontal movement with boom; linear guide bearings and gear-rack drives

Max load on slide: 120 kg

Power sources installed on rail carriage (fixed)

Workpiece capacity/specification

Beam height: 200–2000 mm

Web thickness: 6–40 mm

Flange thickness: 6–40 mm

Flange width: 100–1000 mm

Beam length: 1.5–35 m

Fillet weld dimension: a = 3 mm (or per customer WPS)

Material and joint requirements

Material: Carbon steel

Box beam: up to 1000 × 2000 mm, thickness 6–30 mm

T-profile: up to 800 × 1500 mm, thickness 6–40 mm

Fillet between web and flange for joint tracking: 10 mm

Beams tack welded prior to SAW

Electrical and pneumatic requirements

Mains: 3 phase + (N) + PE, 400 VAC ±10%, 50 Hz ±1 Hz

Compressed air: 6–7 bar, DIN ISO 8573-1 class 2

SAW welding power supply: backup fuse 2 × 100 A; max power 2 × 55 kVA

PEMA semi-portal: backup fuse 1 × 35 A; max power 1 × 12.5 kVA; additional backup fuse 16 A

Additional equipment (not part of the base machine)

PEMA BTS 5000 beam turning devices (2 pcs); electrical: backup fuse 2 × 32 A

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing