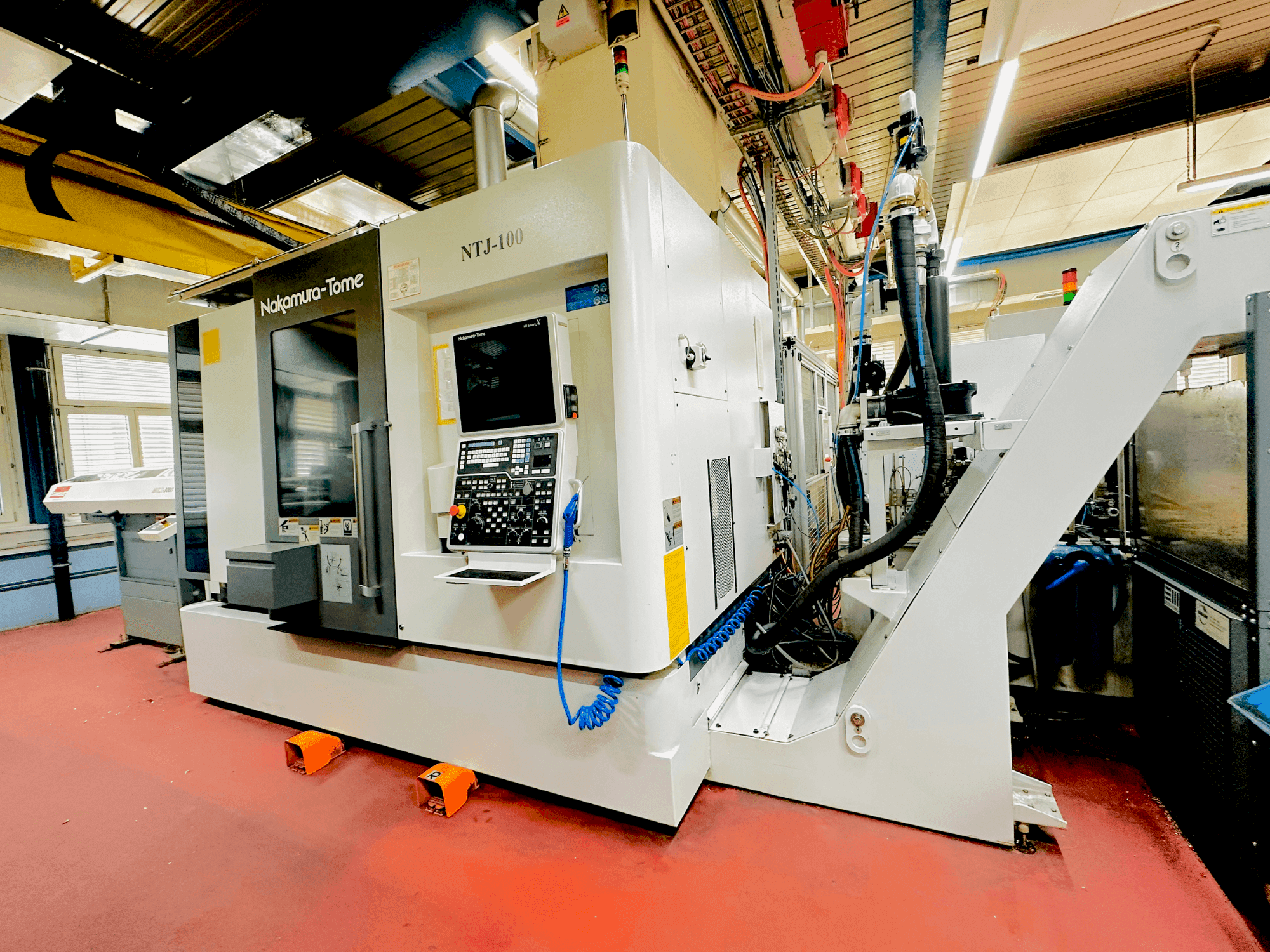

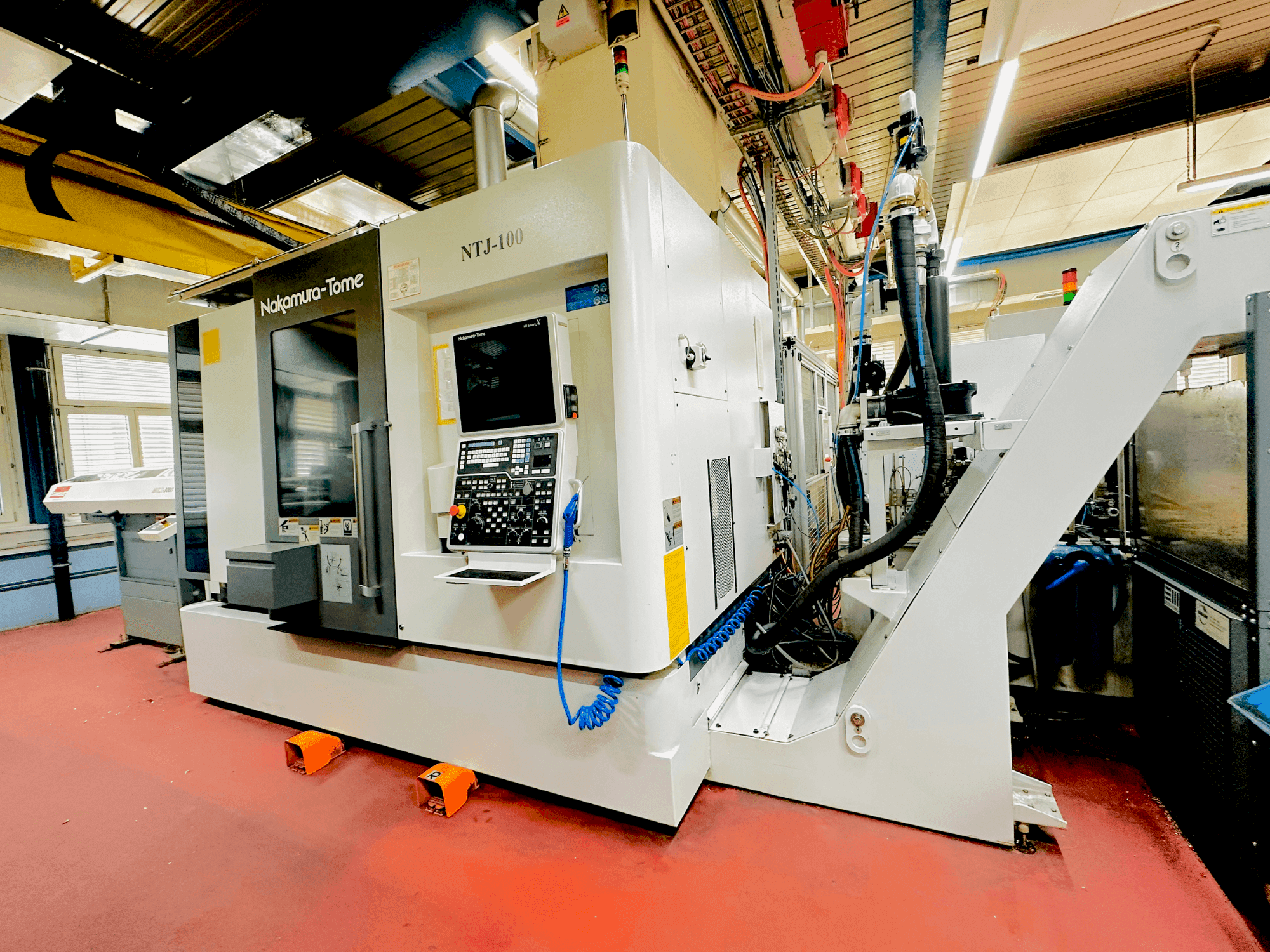

NAKAMURA - NTJ100CH-TUR-NAK-2017-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used NAKAMURA NTJ100 For Sale | gindumac.com

This 9-axis Nakamura NTJ100 turn-mill centre was manufactured in 2017, featuring a bar capacity up to 65 mm and dual spindles with maximum speeds of 4500 and 5000 rpm respectively. It includes a Samsys bar loader, Absolent extraction system, and a variety of automated features such as coolant supply through the spindle, parts catcher, and automatic tool setting devices. Consider the opportunity to buy this Nakamura NTJ100 turn-mill centre. Contact us for more information about this machine.

Overview

- brand: NAKAMURA

- year: 2017

- MODEL: NTJ100

- production hours: 24140

- application type: Turning

- Location: Switzerland

- machine type: Turn-Mill Centre

- control unit brand: FANUC

Technical Information - NAKAMURA NTJ100

Control Unit

- Control Brand: FANUC

- Control Model: 31i-NT-SmartX

Dimensions

- Machine Weight: 10000 kg

Movement

- Number of Axes: 9

Additional Information

Increased bar capacity: 65 mm left, 51 mm right

Workpiece measurement: han-bei measuring probe for automatic workpiece measurement (infrared or radio type) for left and right spindle

Left + right, with auto swing-in type and 2x 4 measuring directions for quick and precise tool setting via the nc function.

Operating time 43399h

Coolant system: coolant through spindle (CTS); coolant float switch for machine stop on low level; additional coolant flushing via the spindle (left and right)

Bar capacity: Ø 51 mm

Parts catcher type A with collecting tray, max. Ø 65 x 150 mm, 3.0 kg, spindle side, left, with plastic lining

Chuck blow-out device for left spindle

Automatic power shut-off

Preparation for oil mist extraction system with connection nozzle Ø 150 mm

Robot/automation prep: pneumatic flap for robot handling on top of the door, opening approx. 400 x 400 mm

Handwheel for manual tracking of defined contours

Data server with 1 GB ATA memory card

Interface for KNOLL system

Triple signal light

Samsys bar loader with a 1.5 m bar loading capacity has the following dimensions: Length: 225 cm + 43 cm intermediate guide Width: 120 cm (including loading ramp and control panel) Height: 145 cm or 180 cm with the flap open

The machine was mainly used to process aluminium (95%).

Additional equipment

Samsys bar loader, including extension

Absolent extraction system

Slat-belt chip conveyor with interface, time-interval control, and alarm evaluation

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing