Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

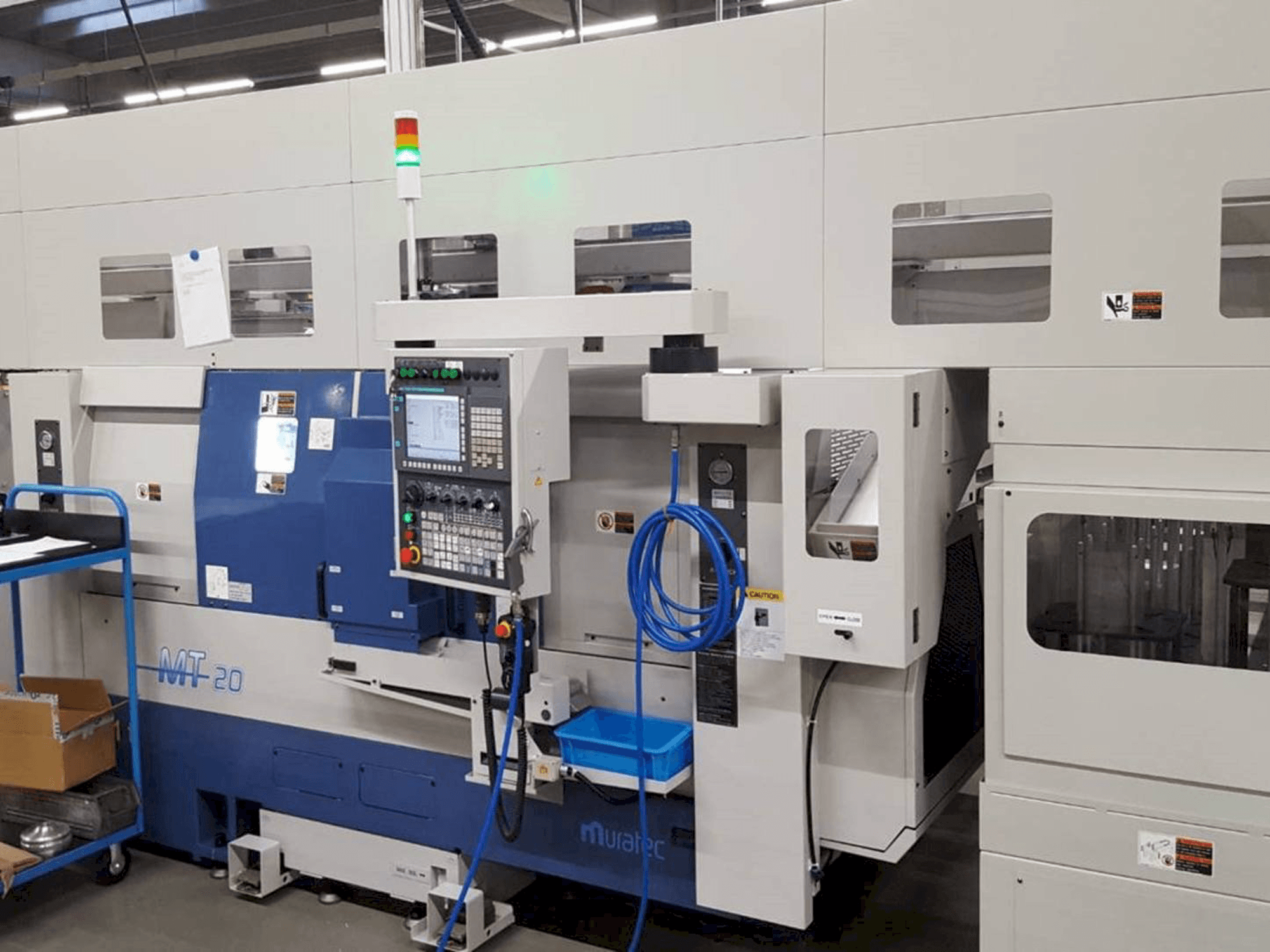

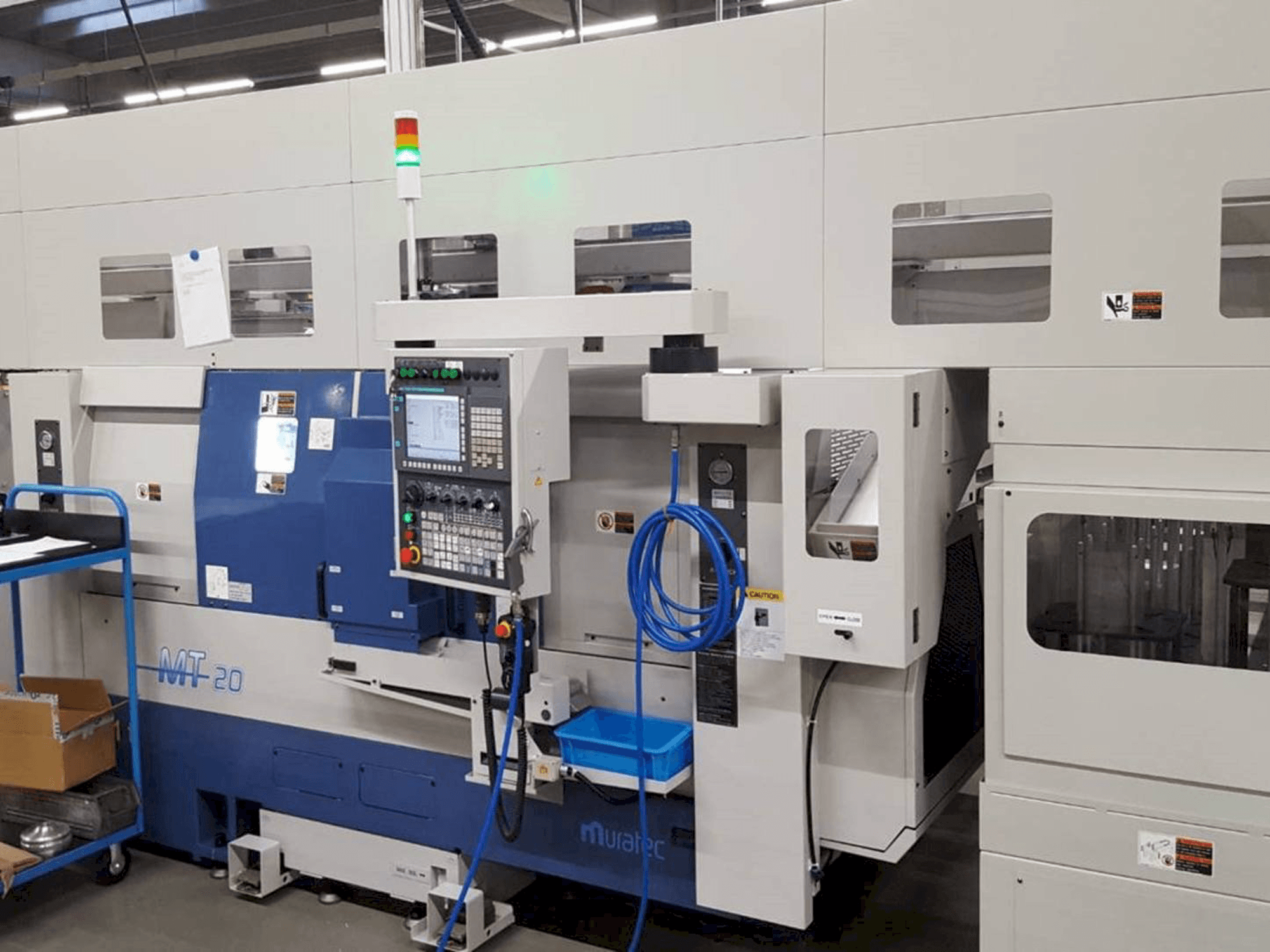

Muratec - MT 20 GYMCES-TUR-MUR-2012-00001

Sold

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Machine Tools

- Muratec MT 20 GYMC Lathe

Show in original language

This Muratec MT 20 GYMC Lathe was manufactured in the year 2012. It has 9 axis. The machine has a spindle speed of 4200 rpm.

Overview

- brand: Muratec

- year: 2012

- MODEL: MT 20 GYMC

- application type: Turning

- Location: Spain

- machine type: Horizontal Turning Machine

Technical Information - Muratec MT 20 GYMC

Dimensions

- Machine Weight: 11000 kg

Movement

- C-axis: 0.001°

- Number of Axes: 9

- X-axis Travel: 230 mm

- Y-axis Travel: 50 mm

- Z-axis Travel: 850 mm

Technical Specification

- Spindle Power: 15 kW

- Spindle Speed: 4200 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Machine in very good condition

- Automatic cleaning using air and coolant for each head, internal cleaning of chips using jets and rain of coolant, automatic control and monitoring of efforts and tool consumption monitor, piece transfer system between heads with automatic torque control.

- Cnc system, servos, cards and fanuc motors, ports for communication via pcmcia card and rs232 port, tool lashing with bmt system. Two 210 mm kitagawa hydraulic plates, turret change indexing time 0. 2 seconds.

- Opening and closing pedal for both plates, distance main spindle - counter spindle max. 1150 mm,

- Power of motorized tool drive motors 3 kw, speed of driven tools 3500 rpm, starting torque of motorized tools 148 nm.

- Fast turret movement speed 24, 20 and 20 m/min for z, y and x axes, complete equipment including static outdoor and indoor tool holders.

- Hinge type rear chip conveyor.

- Electric transformer.

Technical Machine Benefits

- Bar hole 65 mm.

- Machine with two heads, both with c axis, machine with two upper turrets, both with y axis.

- Renishaw automatic tool measuring arms on each head, air and coolant outlet through both spindles.

- Independent high pressure coolant power plant at 50 bars, daikin cooling station for coolant temperature control.

- Engine starting torque 320 nm, 15-position turrets, all of them motorized.

- Interface for bar loader installation, 3-axis gantry type robot for loading and unloading parts.

- Double doll in robot, remote steering wheel and independent programming for robot, digitized programming using gantry robot plc.

- Rapid robot movement speed 120,110 and 35 m/min for z, y and x axes, part loading retry function due to bad support. (rechuking)

- Lubricate all robot axes with oil and grease, part loading retry function due to bad support. (rechuking)

- Warehouse for loading and unloading material with 14 pallets, department for optional unloading of finished parts on the left side of the machine, verification, checking and measurement station for finished parts.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Sergi Guardia

Sergi Guardia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing