Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

KUKA - Palletizing SystemDE-ROB-KUK-2007-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Automation Equipment

- KUKA Palettieranlage 600260060 Robot

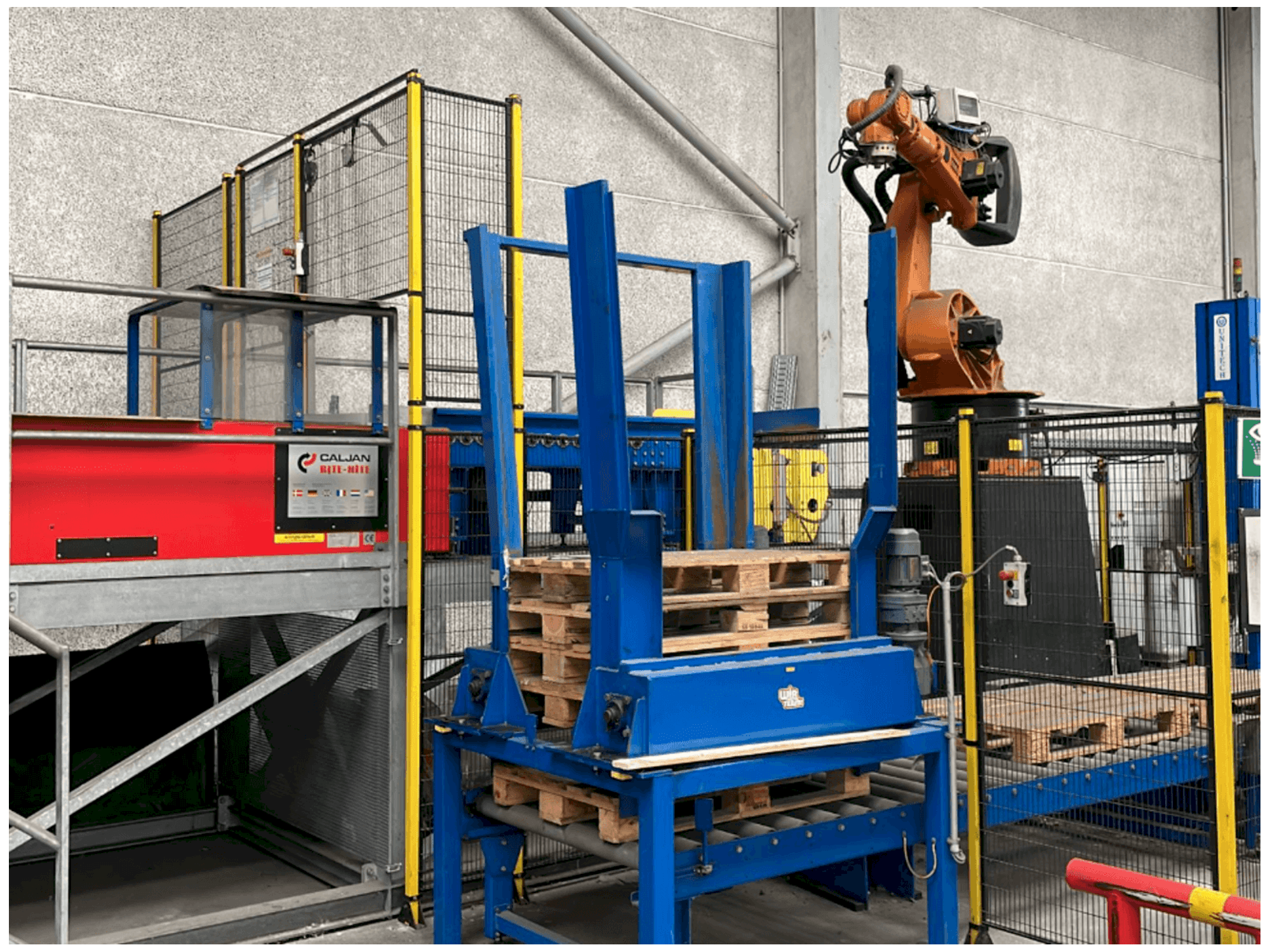

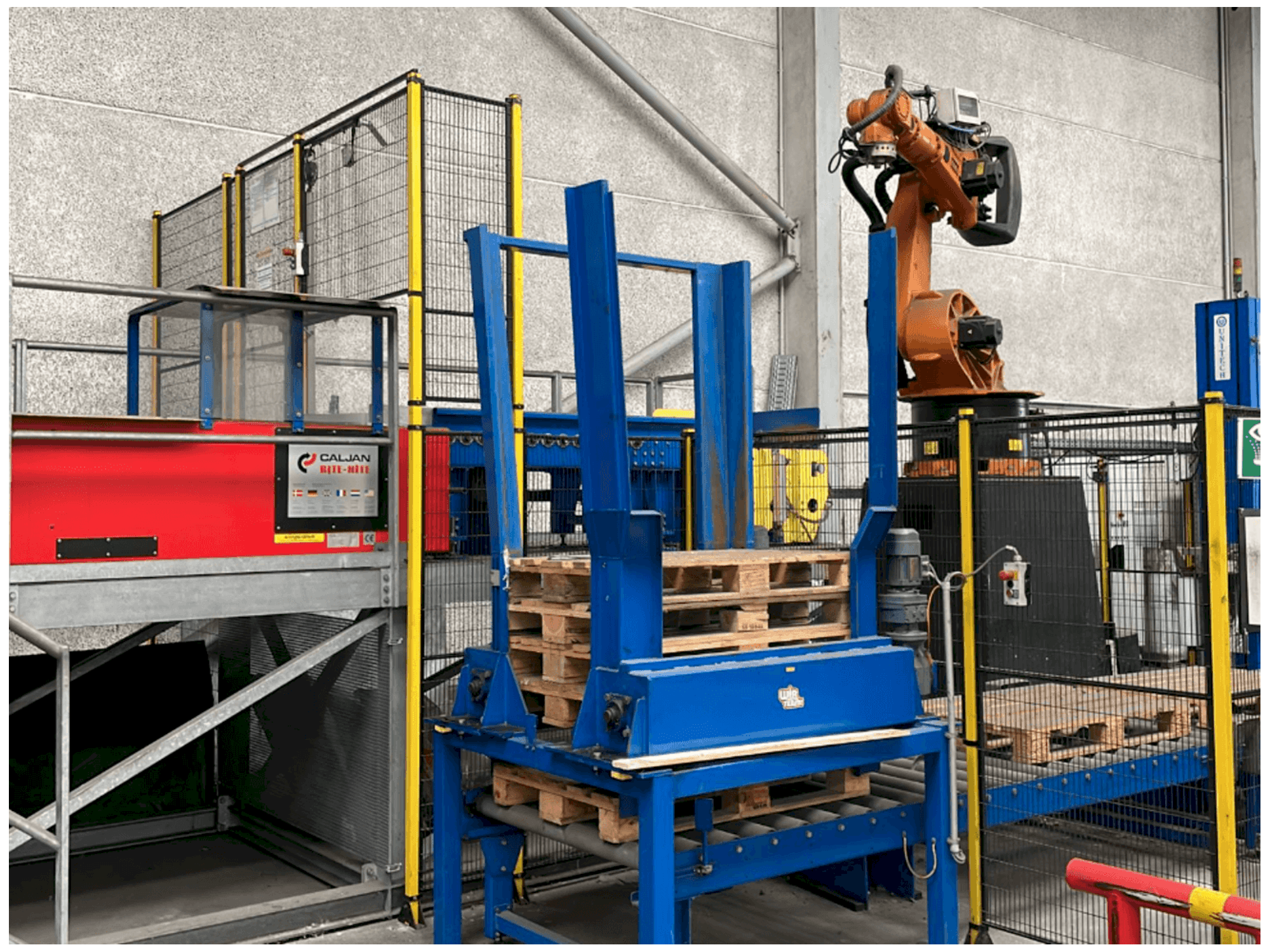

This KUKA Palletizing System was manufactured in the year 2007 by emt automation. The system is designed for the automatic palletizing of carton and bagged goods. Handling is performed by a KUKA robot equipped with a tool changing system so that the products can be gripped with a fork gripper (bag) and a lifting gripper (carton). Depending on the product selection at the operator terminal, the corresponding robot tool is automatically coupled. The products are placed manually on the telescopic conveyor belt and and provided to the robot on the removal conveyor. The pallets, provided in an empty pallet magazine, are fed into the system. Optionally, the filled pallets are wrapped with a film and automatically transported out of the system. See original project description as PDF (German) attached below.

Overview

- brand: KUKA

- year: 2007

- MODEL: Palletizing System

- application type: Other Automation Equipment

- Location: Germany

- machine type: Pallet Handling System

Additional Information

Machine Benefits

Qualitative Machine Benefits

- The system is designed for the automatic palletizing of carton and bagged goods.

- The handling is carried out by a kuka robot equipped with a tool change system so that the products can be gripped with a fork gripper (bag) and a lifting gripper (carton).

- Once the product has been selected on the operating terminal, the corresponding robot tool is automatically coupled.

- The products are manually deposited on the telescopic conveyor and placed on the removal conveyor for the robot.

- The pallets provided in an empty pallet magazine are fed into the system.

- Optionally, the filled pallets are wrapped with a film wrapper and automatically conveyed out of the system.

Technical Machine Benefits

- System components - platform with telescopic conveyor - levelling section - removal conveyor - empty pallet magazine - pallet order technology - safety light barriers - robot

- Kuka kr150l1 50 robot with krc 2 controller performs the handling

- The system is operated via the siematic op170b and the kuka control panel (kcp)

- All preconfigured palletizing patterns can be palletized

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing