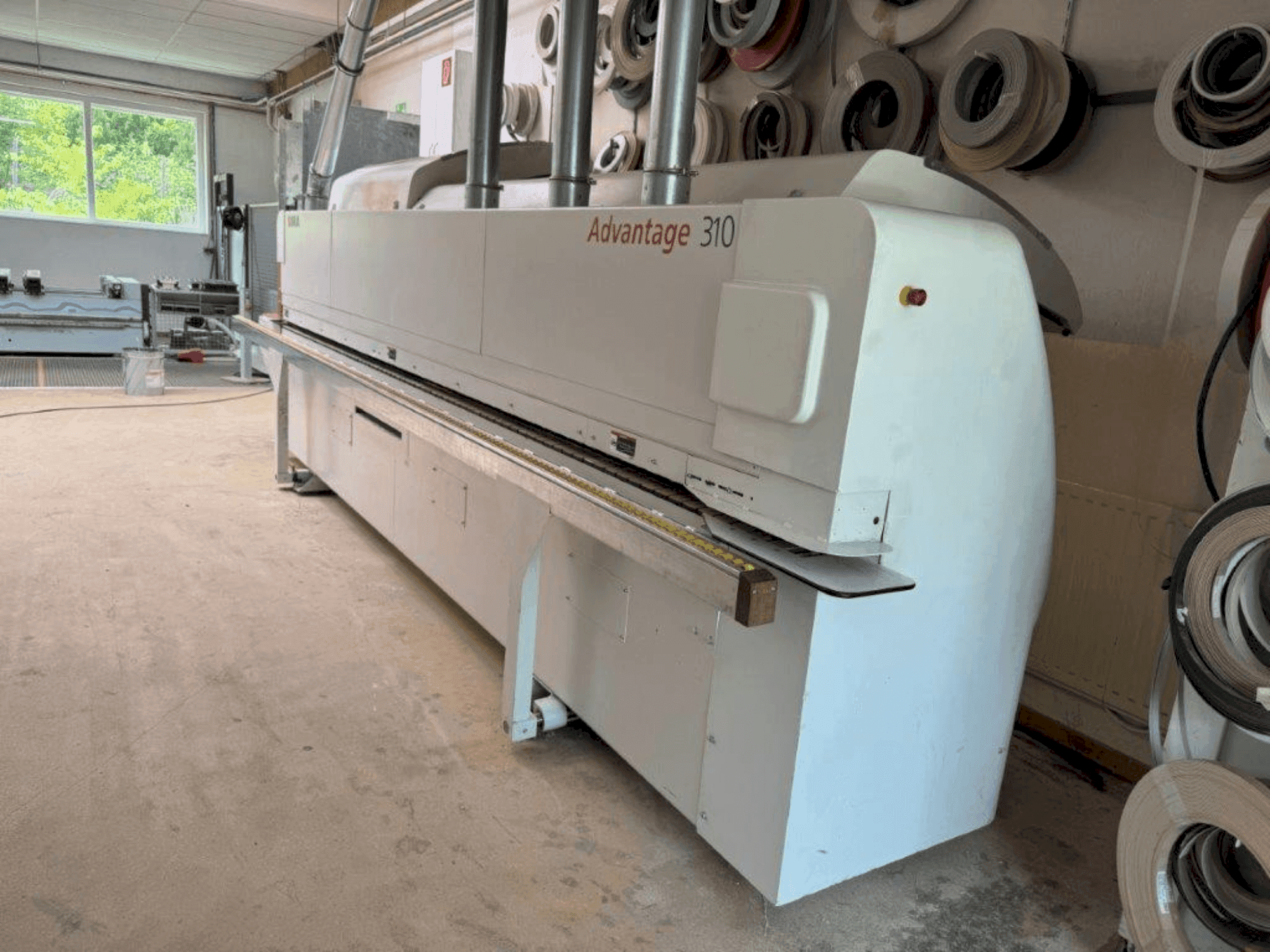

IMA - ADVANTAGE 310DE-EDG-IMA-2010-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used IMA ADVANTAGE 310 For Sale | gindumac.com

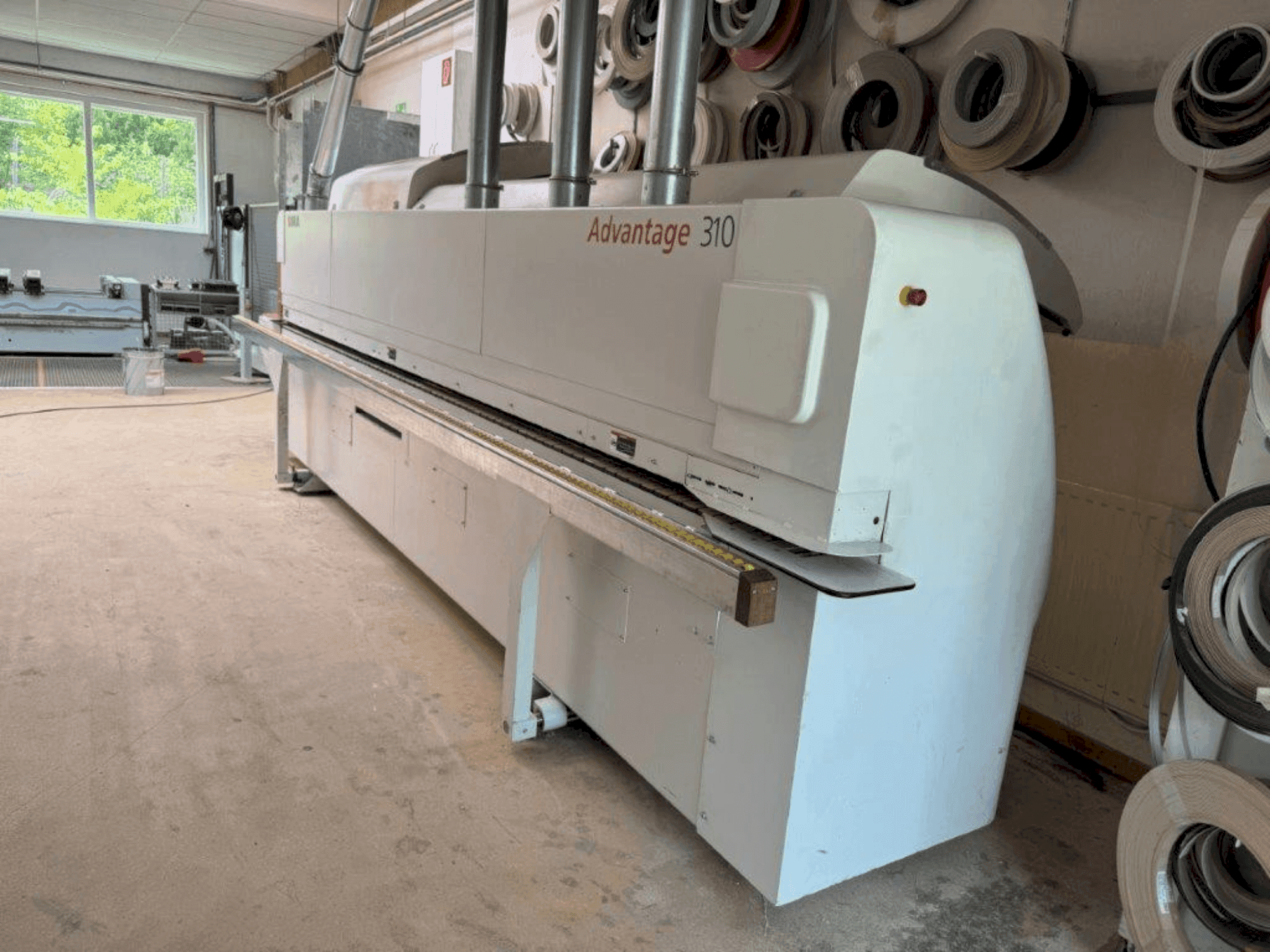

This IMA Advantage 310 edgebander was manufactured in 2010. It handles workpieces from 150 mm in length and 65 mm in width, with thicknesses up to 60 mm. It's equipped for various materials including chipboard and MDF, using melamine, paper, foil, or veneer edges. Features include a gluing unit, cutting unit, and a buffing unit, enhancing finishing processes. Consider the opportunity to buy this IMA Advantage 310 edgebander. Contact us for more information about this machine.

Overview

- brand: IMA

- year: 2010

- MODEL: ADVANTAGE 310

- application type: Edge Banding

- Location: Germany

- machine type: Edgebander

Additional Information

Machine Benefits

Technical Machine Benefits

- Minimum workpiece length: 150 mm

- Minimum workpiece width: 65 mm (with max thickness of 25 mm), 150 mm

- Workpiece thickness: min. 8 mm, 12 mm with profile scraper blades; max. 40 mm (mfa 08346), 60 mm (skf)

- Smallest workpiece: 65 x 300 mm / 150 x 150 x 19 mm

- Machining allowance per workpiece edge: 0 - 5 mm

- Workpiece shape: rectangular

- Material: chipboard, mdf

- Surface material: direct coating (melamine resin paper), paper, foil, veneer

Extra Information

Edging Material Roll material without foil: Paper edges & plastic edges: 0.3 - 3.0 mm Veneer edges: 0.5 - 3.0 mm Max. edge cross-section: 150 - 180 mm² Cut-to-length edge strips: Strips: 3.0 - 8.0 mm Max. strip cross-section: 520 mm² Edge height: Min. 12 mm, max. 65 mm Max. upper edge overhang: 2 mm Edge profiles: Paper edge: Approx. 0.4 mm, bevel 15° Plastic edge up to 3.0 mm, depending on radius tool Milling strip flush up to 8 mm Machine Constant workpiece projection from the chain track: 35 mm + edge thickness Max. cutting cross-section: 520 mm² Passage width: Min. 65 mm (with 35 mm projection) Min. workpiece length in feed direction: 150 mm Basic height (top edge of chain track): 940 mm Aggregate side: Left in feed direction Pneumatic connection: Approx. 7 - 8 bar Joining Unit 08.379 and Blow Nozzle 2 motors 4 kW each, 9000 rpm Gluing Unit 283.1513 Glue dispenser 0.8 l, 60 mm high Suitable for hot melt or PU glue With single roller/strip magazine, roller diameter 800 mm 3 main pressure rollers and 3 pressure rollers Cutting Unit 08.415 Pneumatically swivels to 0° or 8 2 motors, 12,000 rpm 2 HM cross-cut saw blades Copy Trimming Unit SKF-L 4 motors, 12,000 rpm Profile length in throughfeed direction: Max. approx. 50 mm Workpiece thickness: Max. 60 mm Working speed: Max. approx. 20 m/min Distance between 2 workpieces: Min. approx. 400 mm Profile Scraper Unit 08.519 For rescraping an upper and lower milled quarter circle profile Self-Scanning Scraper Unit 08.521 For removing hot melt adhesive residue from the edge area of the top and bottom of workpieces Buffing Unit 08.617-2 Upper and lower motor: 180 W, 1400 rpm 2 polishing wheels 50 x 160 x 19 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing