Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

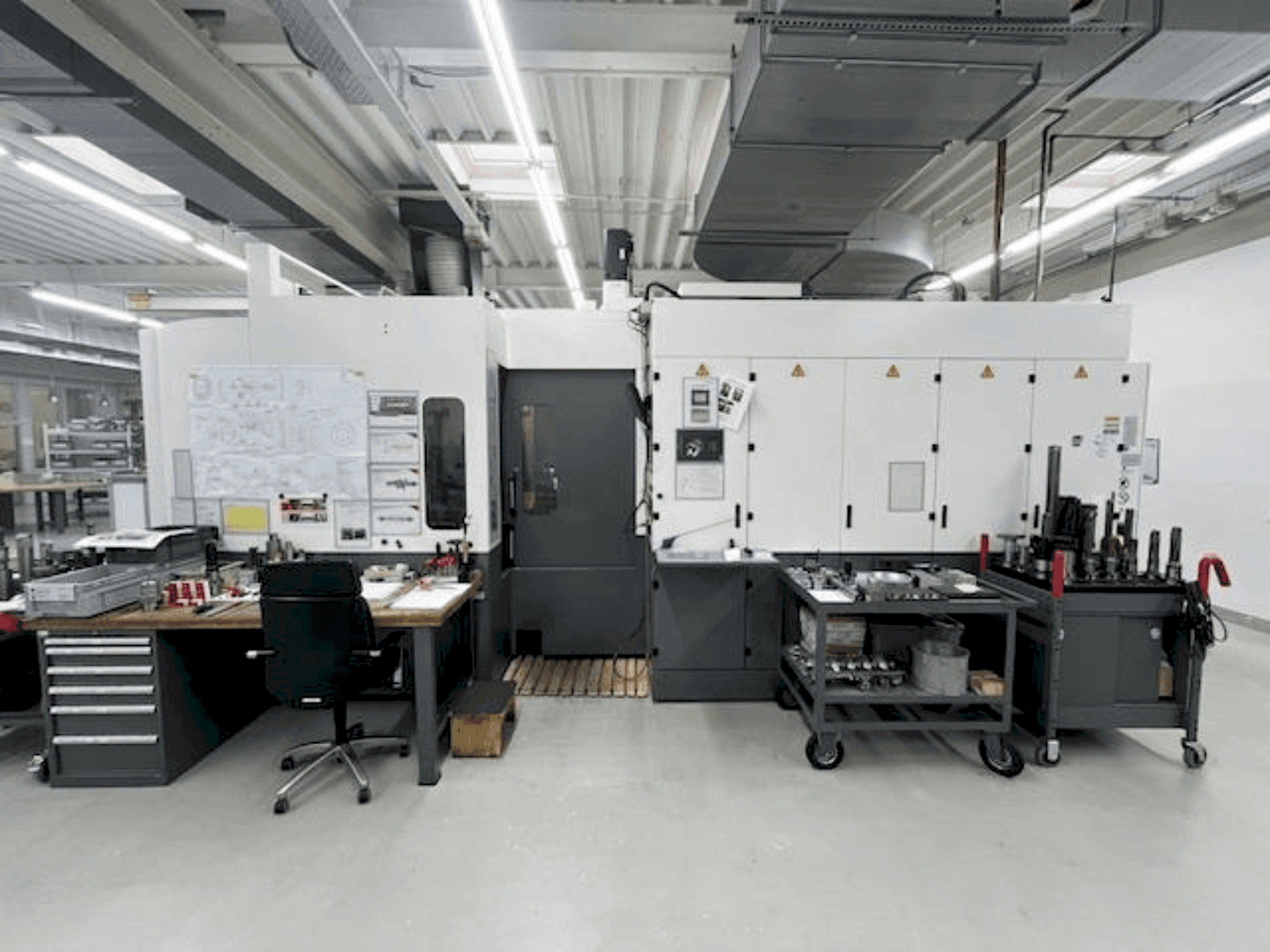

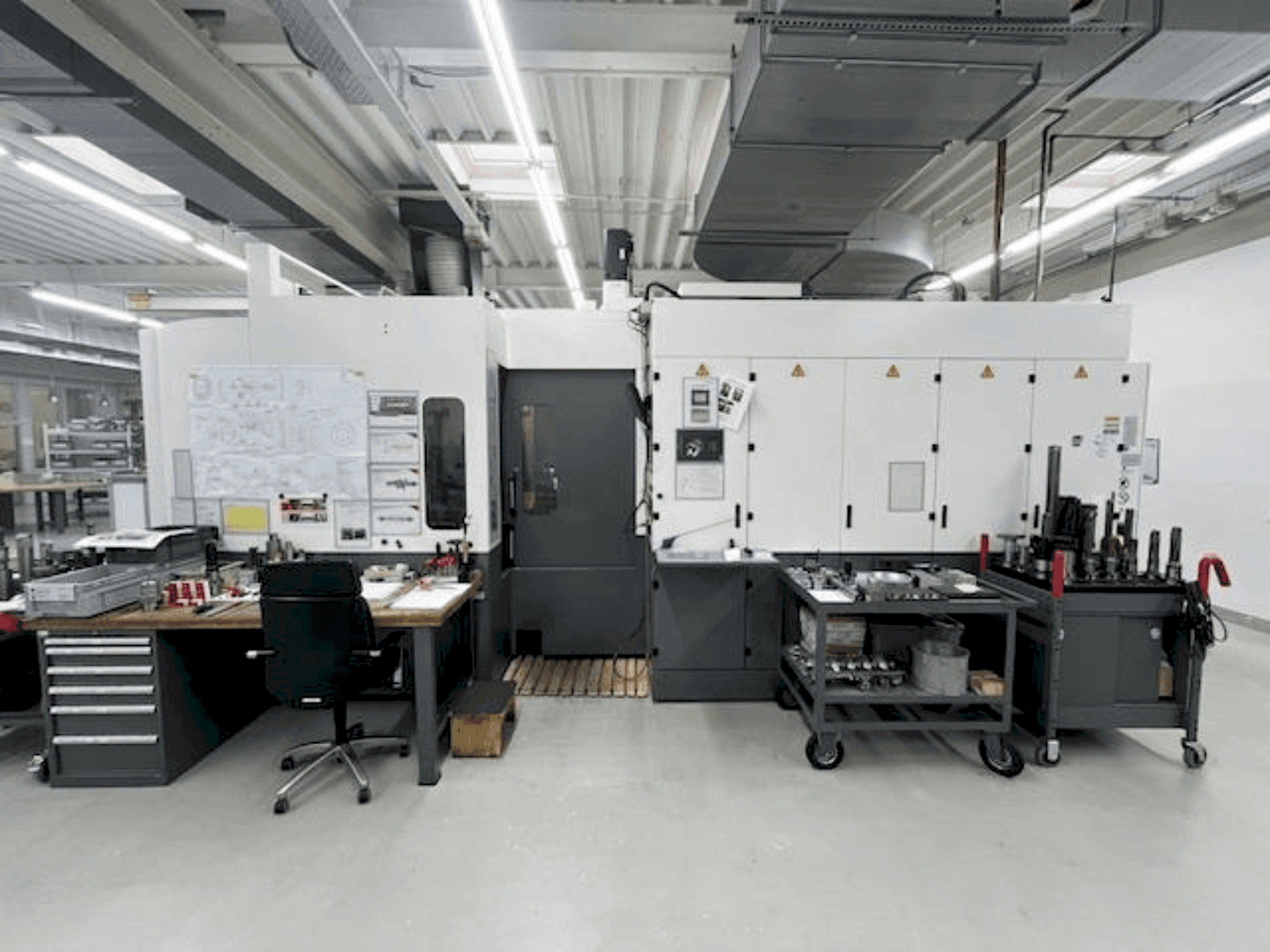

HULLER HILLE - Nbh 170DE-MIL-HUL-1998-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used HULLER HILLE Nbh 170 For Sale | gindumac.com

This 4-axis HULLER HILLE NbH 170 horizontal machining center was manufactured in 1998. It features a robust CNC Siemens SINUMERIK 840 C control system, a spindle capable of 25 to 12,000 rpm with ceramic bearings, and a dual pallet system with 180° rotation. The machine includes a high-capacity tool magazine and an advanced coolant system with chip conveyor. If you are looking to get high-quality machining capabilities, consider the HULLER HILLE NbH 170 machine we have for sale. Contact us for more information.

Overview

- brand: HULLER HILLE

- year: 1998

- MODEL: Nbh 170

- application type: Milling

- Location: Germany

- machine type: Horizontal Machining Centre

- control unit brand: SIEMENS

Technical Information - HULLER HILLE Nbh 170

Control Unit

- Control Brand: SIEMENS

- Control Model: SINUMERIK 840C

Technical Specification

- Spindle Power: 46 kW

- Spindle Speed: 12000 RPM

Additional Information

Additional equipment

- Table: 1 NC Table (B-Axis): Smallest Step Size: 0.001 degrees / Repeatability: ± 0.001 degrees / Accuracy Across All Positions: ± 0.002 degrees / Allowable Moments on Locked Table: Max Tangential Moment: 7000 Nm/ Max Tilting Moment: 16000 Nm

- Clamping Forces: At Table: 147000 Nm / At Pallet: 84600 Nm

- Tools: Tool Holder: HSK-A100, per DIN 69 893 / Tool Magazine holds 2 magazine cassettes / 1 Magazine Cassette with 50 tool slots for SK50 tools / Tool Cone Cleaning System for HSK-A100

- Coolant System: with integrated chip conveyor / Coolant Pump: Q = 30 l/min, 10 bar for internal and external coolant supply via the work spindle

- System Pressure: Up to 50 bar for internal coolant supply / Flow Rate: 30 l/min at 10 bar to 10 l/min at 50 bar

- Filter: Bagless trough belt filter / 2 Cross Conveyors in the X-axis / Chip Conveyor with 1200 mm discharge height

- Automatic Central Lubrication

- Extraction Connection for oil and coolant mist separator

- Rotating Clear View Window: VISIPORT

Machine Benefits

Technical Machine Benefits

- Spindle stock with ceramic bearings

- Power: 36. 0 kw (100% duty cycle)

- Torque: 344 nm (100% duty cycle)

- Extension of the base machine: y = 800 mm

- 180° pallet change system: with 4 x 90° pallet rotation mechanism / 2 pallets with clamping surface of 500 mm x 630 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing