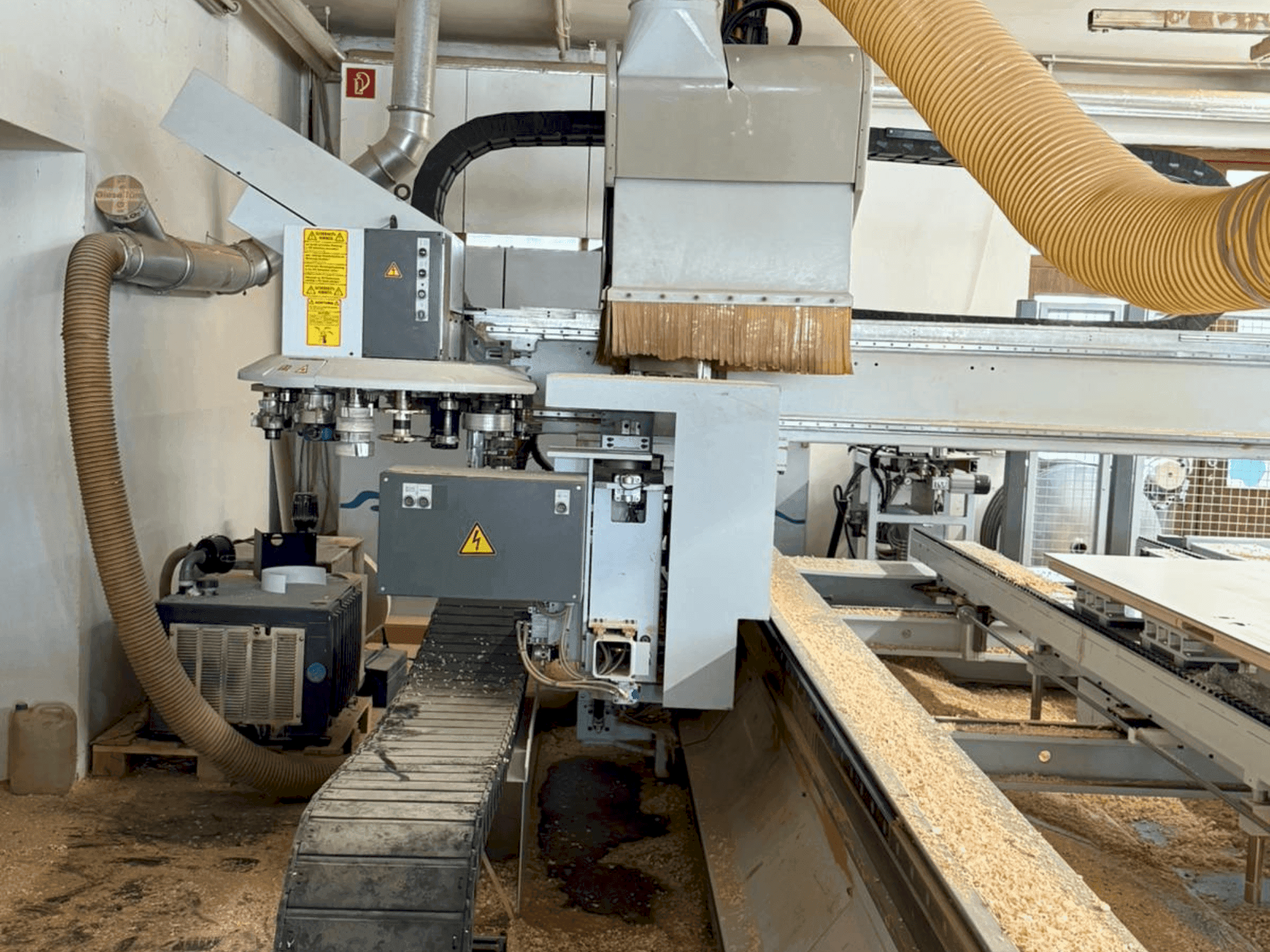

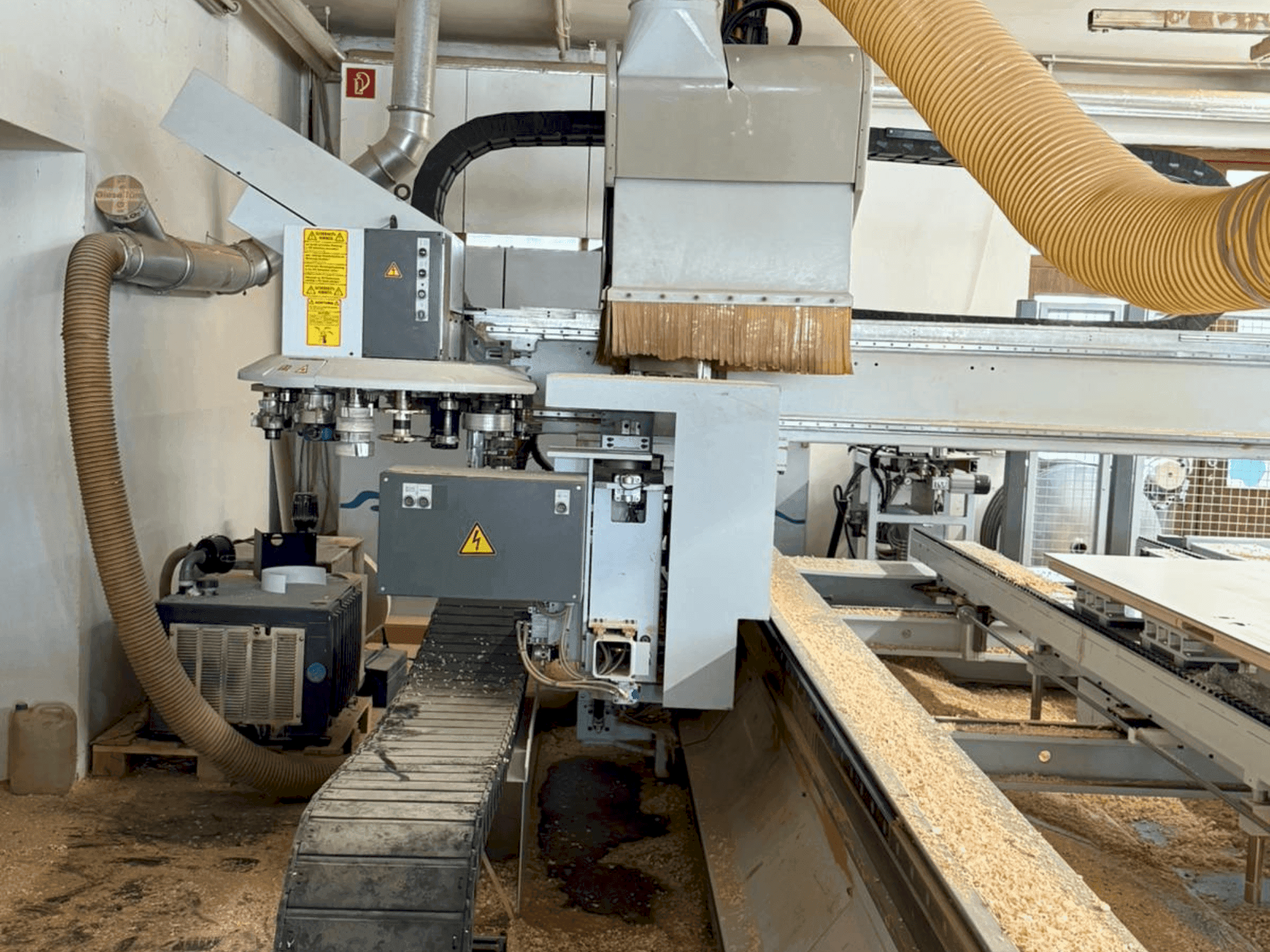

HOMAG - PROFI BAZ20/30/16/V/DDE-CNC-HOM-2003-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG PROFI BAZ20/30/16/V/D For Sale | gindumac.com

This 4-axis HOMAG PROFI BAZ20/30/16/V/D was manufactured in 2003. It features a Homatic CNC control, WOODWOP CNC programming, an 18-position disk changer, and a main spindle with a 12 kW three-phase motor. Capable of handling workpieces up to 3000 mm in length and 1400 mm in width, it includes a continuous table with adjustable vacuum clamps. Consider the opportunity to buy this HOMAG PROFI BAZ20/30/16/V/D CNC Wood Machining Centre. Contact us for more information.

Overview

- brand: HOMAG

- year: 2003

- MODEL: PROFI BAZ20/30/16/V/D

- application type: CNC Wood Machining

- Location: Germany

- machine type: CNC Wood Machining Centre

- Available from: 01/09/2026

Technical Information - HOMAG PROFI BAZ20/30/16/V/D

Movement

- Number of Axes: 4

Technical Specification

- Spindle Speed: 18000 RPM

Additional Information

Control/Software: Homatic CNC control; WOODWOP CNC programming system; Postprocessor

Workpiece capacity:

Length 800–3000 mm; Width 350–1400 mm; Thickness max. 70 mm with edge / 80 mm milling

Frieze width min. 120 mm; Weight max. 150 kg

Table/Clamping:

Continuous table (D-table)

Longitudinal console 1 fixed; Longitudinal console 2 manual Y-width adjustment

8 vacuum clamps 125 x 50 x 100 mm

Working height lower edge of workpiece 950 mm

Unit for moving vacuum clamps on unit carrier with pneumatic extension console (max. 4 clamps per longitudinal console)

Width adjustment (longitudinal console/D-table): Servo drive, per longitudinal console

Stop bolt for top layer overhang: Lifting/rotating device, max. 20 mm top layer, stroke 110 mm, individually selectable, end-position monitored (for manual door placement)

Main spindle:

Speed 1500–18000 rpm (VFD 15 kW), full rated power from 12000 rpm

Tool diameter max. 180 mm (milling) / 200 mm (grinding); Room extraction for all tools/units

Aggregate interface/C-axis:

Pneumatic and swivel drive interface

C-axis with torque drive and 3-point support

Tool changer:

18-position disk changer for HSK F63; tool weight 6 kg; tool length max. 200 mm

Configurations: 18 x Ø max. 130 mm; or 9 x Ø max. 180 mm + 9 x Ø max. 70 mm; grinding tools Ø max. 200 mm

Changer raisable for traveling pickup (left side)

Units/aggregates (for tool changer unless noted):

Drilling/milling unit, 4 spindles: ER25 up to Ø16 mm shank, protrusion max. 50 mm, speed max. 13500 rpm, unlimited swivel via C-axis

Lock case milling unit, 2 spindles D=16/20: counter-rotating, 12000 rpm, integrated blow-out, unlimited swivel via C-axis

Swiveling saw/drill unit: manual 0–90°, flange Ø30 mm, TK Ø52 mm, prepared for crosscut saw Ø max. 180 mm, drill chuck with Weldon D=10 mm, speed max. 9000 rpm, C-axis swivel

Milling cutter holder D=30 with chip guide: mandrel length 45/80 mm, chip guide plate controlled via C-axis, changer space Ø 140 mm

Flush milling unit: simultaneous top/bottom, edge radius max. R12 mm, min. outer radius ~R5 mm / inner radius ~R30 mm at 90°, scanning top/bottom/side, unlimited C-axis swivel, speed max. 12000 rpm, workpiece thickness max. 50 mm, min. overhang ~35 mm, with narrow feeler shoes

WPL knife head: run-out angle 5°, Ø 70 mm

Gluing/edgebanding equipment:

Drive spindle/V for gluing units: mounted right side of boom; cross slide with Y anti-reb and Z extension stroke; anti-reb spindle with C-axis and electrical/electronic interface; dedicated Z-axis

Gluing unit 4 sides, 90 mm (for main spindle): straight edges with direct glue application; 1 pre-press roller + 1 pneumatic post-press roller (programmable); inner radius min. R40 at 90°; edge height max. 90 mm; veneer thickness 0.4–1 mm; folding pressure zone on main spindle with hot-melt reactivation

Edge hold-down device, manual adjustment

Magazine/pickup:

Pickup space on X-support for interchangeable special unit (e.g., motor-driven swiveling machining spindle)

Connectivity: Ethernet network connection

Additional equipment

Chip conveyor belt: Integrated chip/scrap disposal via chip belt below longitudinal crossbars

Vacuum pump: 100/140 m³/h

External pre-chopping station with 3-stage roller, automatic:

Roller turntable on operator side; roller Ø 800 mm

Edge length min. 350 mm; edge height max. 90 mm

Residual edge length monitoring with feed stop at 2400 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to HOMAG PROFI BAZ20/30/16/V/D

BIMA 310 120/300

IMA - CNC Wood Machining Centre

KM-95 G1

KRÜSI - CNC Wood Machining Centre

BIMA CUT 120/300

IMA - CNC Processing Center

ProTec 571

GANNOMAT - CNC Wood Machining Centre

BIMA CUT 120/240

IMA - CNC Wood Machining Centre

Mastercraft 2137

OMAKSAN - CNC Wood Machining Centre

ELECNC 2200x3700

BLUE ELEPHANT - CNC Router

MD TOP XLS CA2

COMEC - CNC Wood Machining Centre

Speed-Cut SC1

HUNDEGGER - CNC Wood Machining Centre

PROFI BMG 512/40/12/V/A

HOMAG - CNC Processing Center

BIMA CUT 145/330

IMA - CNC Wood Machining Centre

MD TOP XL

COMEC - CNC Wood Machining Centre