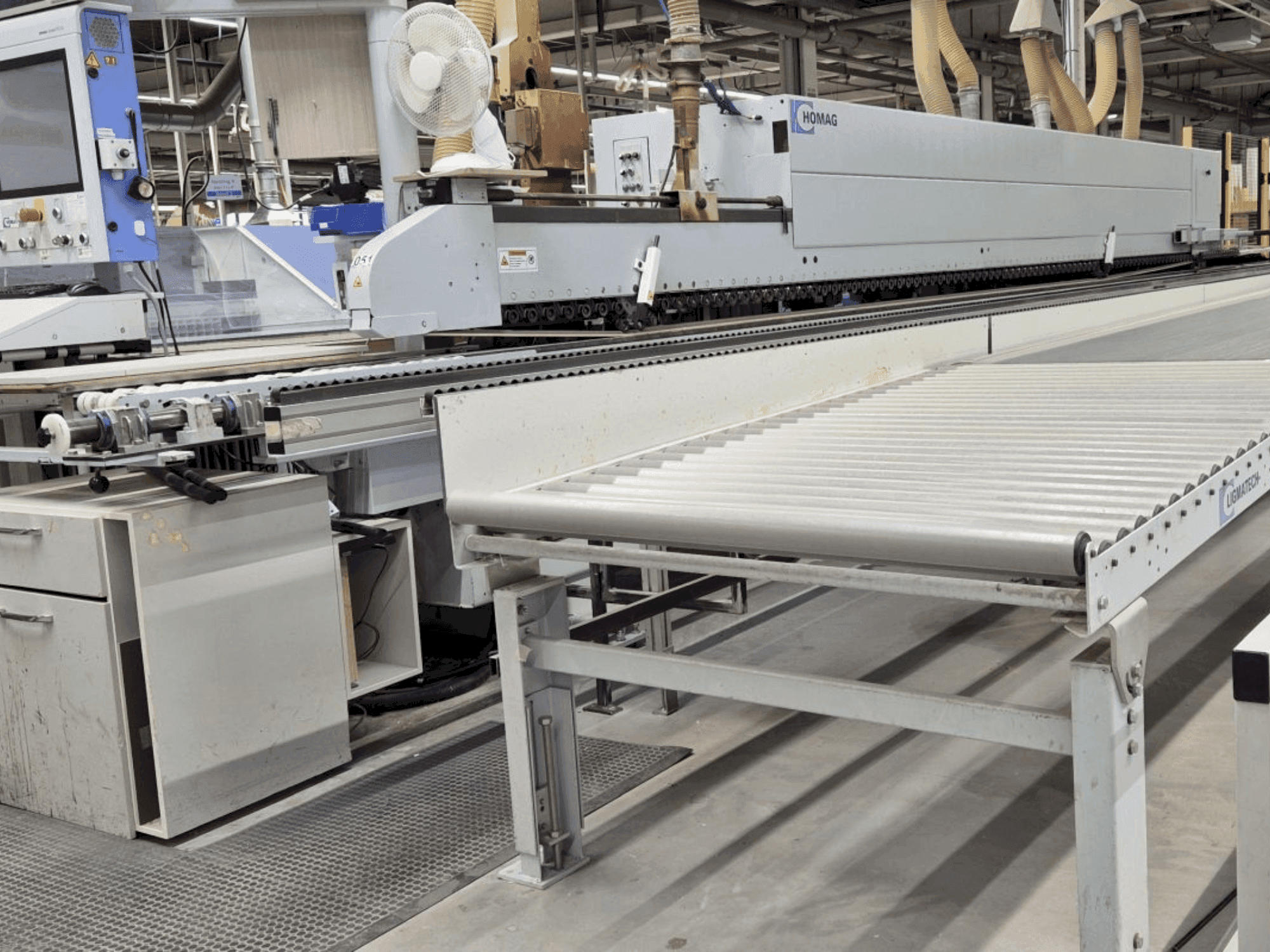

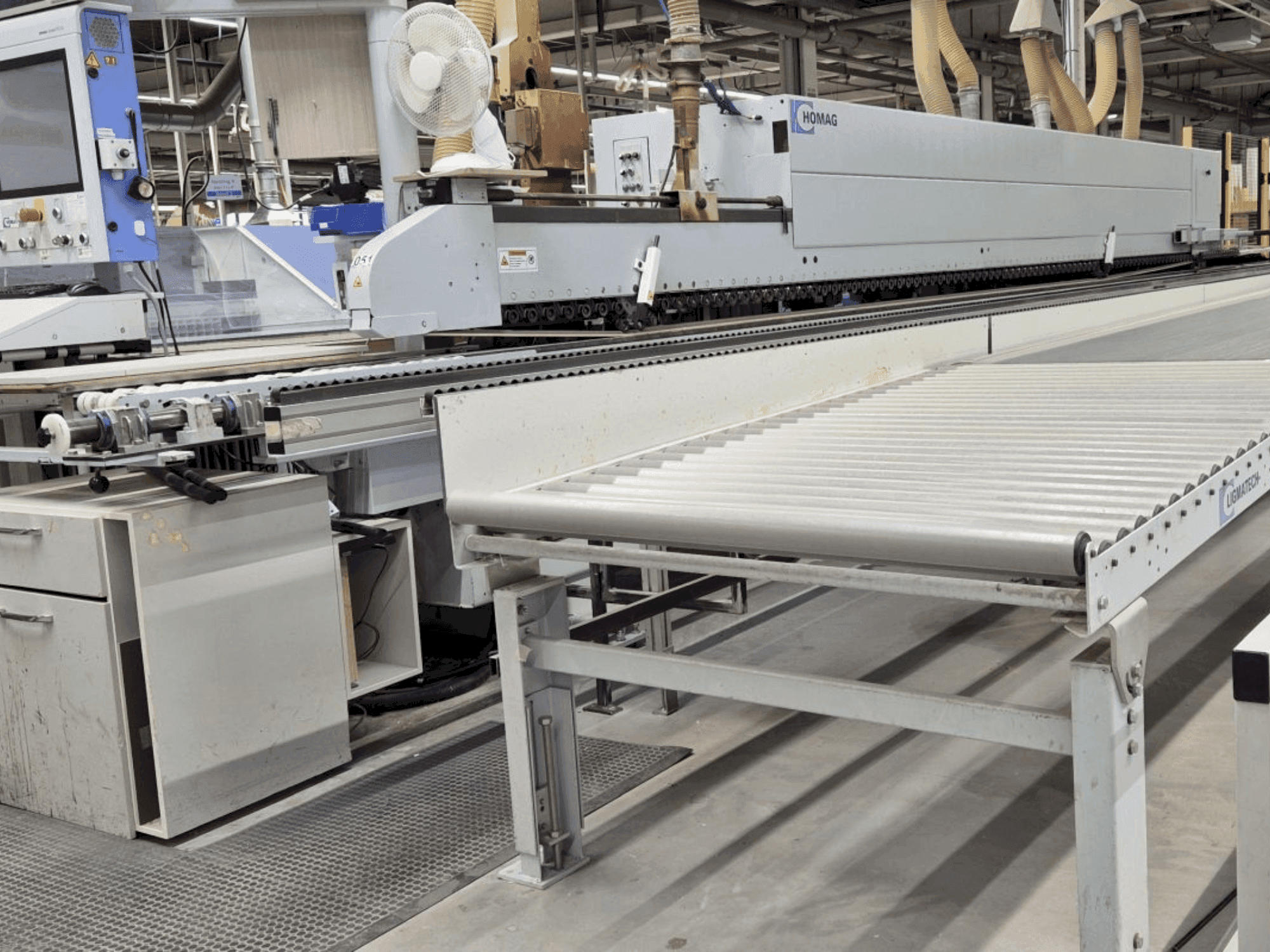

HOMAG - KAL 310/7/A3DE-EDG-HOM-2010-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG KAL 310/7/A3 For Sale | gindumac.com

This HOMAG KAL 310/7/A3 was manufactured in 2010. A used single-sided edge banding machine featuring a 28-position ISAS edge magazine, PU gluing unit, and Boomerang return system. It includes a joint milling unit with two motors and a PU 34 gluing system with a capacity up to 6 kg/h. Ideal for precise edge banding applications. Contact us for more information about this machine.

Overview

- brand: HOMAG

- year: 2010

- MODEL: KAL 310/7/A3

- application type: Edge Banding

- Location: Germany

- machine type: Edgebander

Additional Information

ISAS edge magazine: 28 positions (selectable edges)

Gluing unit: PU 34 system with PU melting unit (capacity up to 6 kg/h), 2 kg adhesive container, QA glue application unit

Pressure section: 4 pressure rollers

Separating agent spray unit: Top and bottom application

Joint milling unit: 2 motors, each 3 kW, 150 Hz, 9,000 rpm; pneumatically controlled for infeed milling operation

Pre-milling unit: 2 motors, each 0.55 kW, 200 Hz, 12,000 rpm; double roller tracing; electro-pneumatic retraction

End trimming unit (WK 13 – chamfer/straight): 2 motors, each 0.4 kW, 200 Hz, 12,000 rpm; electro-pneumatic adjustment to 2 positions (flush and overhang)

Profile unit FK 11 (manual): For processing edge overhangs top/bottom and trimming front/rear edges; 2 motors, each 0.4 kW, 200 Hz, 12,000 rpm

Universal milling unit UF 11: 1 motor 4 kW, 150 Hz, 9,000 rpm; swiveling 90°, electro-pneumatically controlled; HSK 63 F tool holder with push-button release

Profile scraper unit PN 10: Pneumatic adjustment for lateral retraction from the working area

Finish unit FA 11 (top/bottom): Glue joint scraper; cleaning fluid application; buffing unit with 2 motors; height-adjustable with upper pressure beam

Machine control: 19-inch touchscreen operation

Additional equipment

Return conveyor system: BOOMERANG ZHR05

Inclined air cushion table: length 2,000 mm, width 1,000 mm

Conveyor belt width: 1,100 mm

Workpiece parameters:

Length: 300–2,500 mm

Width: 60–1,100 mm, or length 300–800 mm with width >1,100–2,000 mm

Thickness: 8–60 mm

For four-sided processing: Min part 300 x 300 mm; Max part 2,000 x 800 mm

Roller support rail for wide parts

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing

Products related to HOMAG KAL 310/7/A3

COMBIMA

IMA - Edgebander

ARCUS 1334 FV2

HOLZHER - Edgebander

Ambition 1660 FGC

BRANDT - Edgebander

KDF 890 2CU

BRANDT - Edgebander

PROFI BMG 512/40/12/V/A

HOMAG - CNC Processing Center

B 85 K

LANGE - Edgebander

Combima Systems/I/R75/1370

IMA - Edgebander

Combima/II/390/B/L12

IMA - Double Sided Edgebander

Combima Systems / I/R751220/R3

IMA - Edgebander

TEMPORA 60.06 glueBox x-motion

FORMAT4 - Edgebander

FORMAT 4 Tempora60.06LX

FELDER - Edgebander

KDF 991

BRANDT - Edgebander