Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

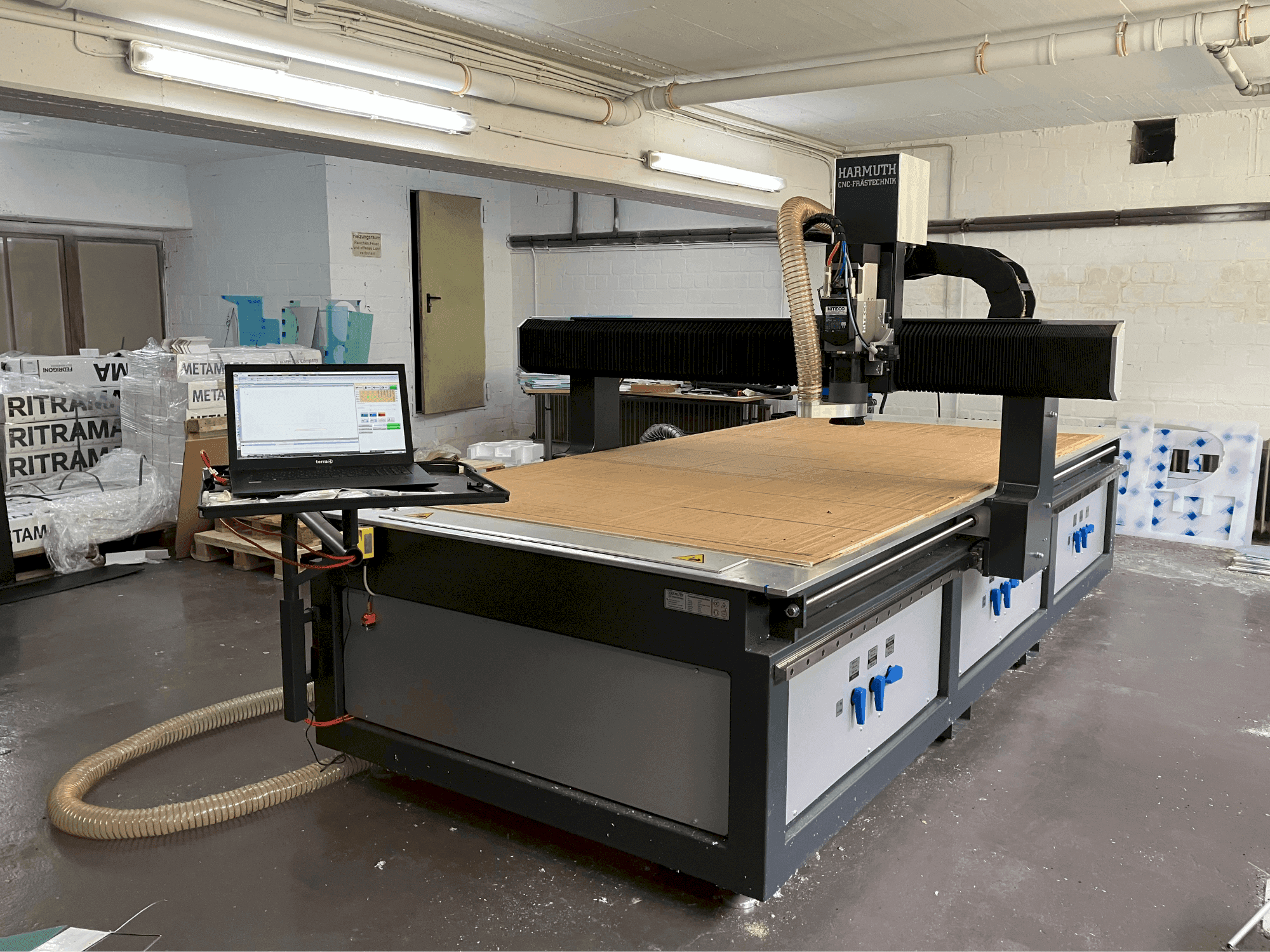

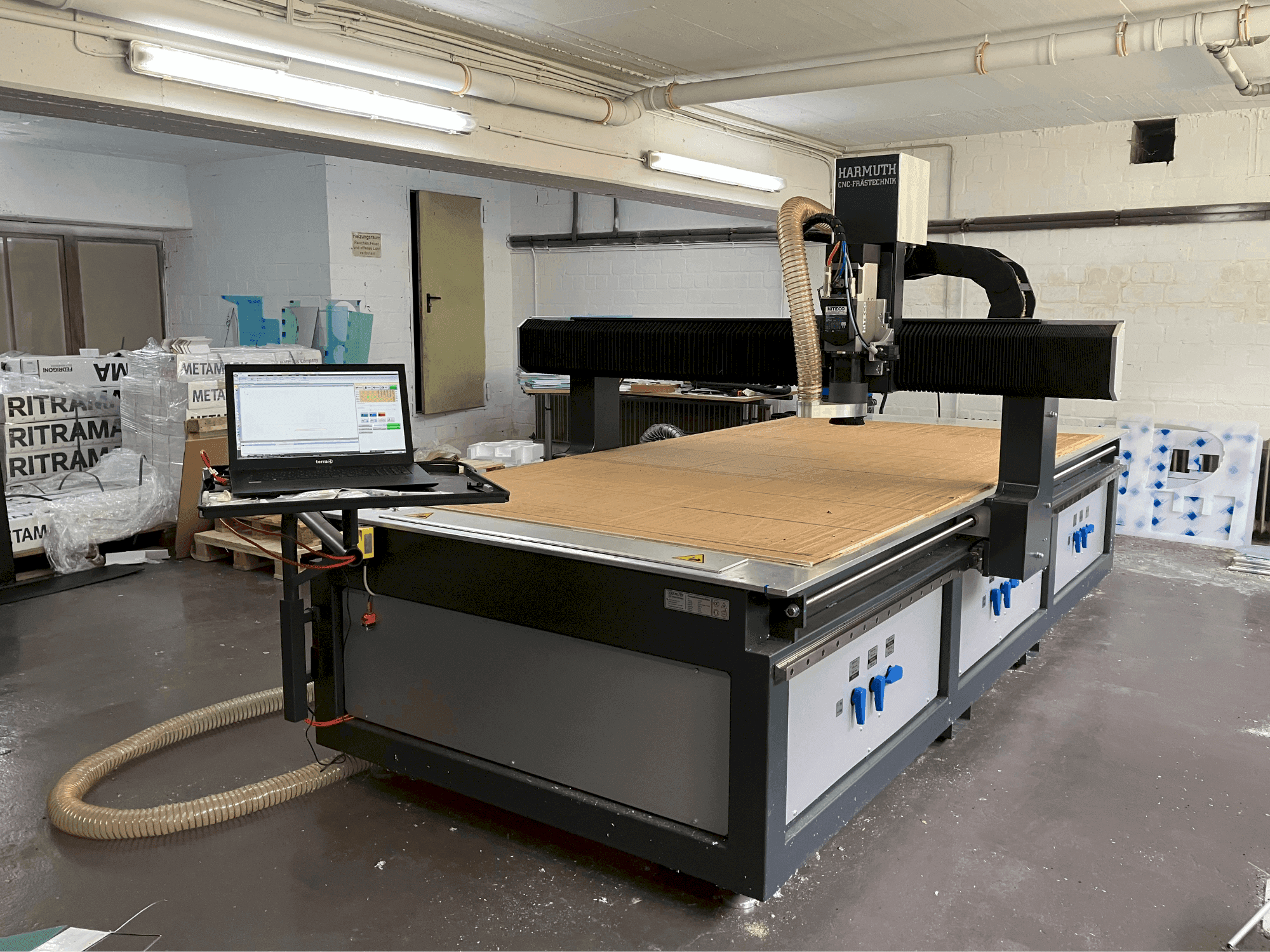

HARMUTH - F+3000DE-MIL-HAR-2020-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HARMUTH F+3000 For Sale | gindumac.com

This 3-axis HARMUTH F+3000 wood working machine was manufactured in 2020. It features a robust steel base and heavy aluminum portal for vibration-free milling. The working area measures 3150mm x 1560mm x 270mm. It includes a vacuum table, a high-speed milling spindle capable of 300-24,000 rpm, and a 10-fold tool changer. The machine is controlled via the intuitive Penta-Tec software. If you are looking to get high-quality milling capabilities, consider the HARMUTH F+3000 machine we have for sale. Contact us for more information.

Overview

- brand: HARMUTH

- year: 2020

- MODEL: F+3000

- application type: Other Woodworking Machinery

- Location: Germany

- machine type: Other (Wood)

Additional Information

Machine Benefits

Technical Machine Benefits

- Spindle speed range: 300 - 24vibration-free milling, stepper motor drive system, automatic functions in control software qualitative machine benefits: point laser for zero point approach, optical registration mark detection,000 rpm /spindle motor power: 3. 8 kw /tool taper: sk30

- Vibration-free milling, stepper motor drive system, automatic functions in control software / qualitative machine benefits: point laser for zero point approach, optical registration mark detection

Extra Information

-External dimensions: length = 3760 + operating unit 1200mm, width 2500mm, height 2000mm. Machine base is completely made of steel Portal made of heavy aluminum profile (40KG/m) for vibration -free milling Drives are via ball screws (20x20mm X/Y and 16x5mm for the Z-axis) Stepper motor drive system Positioning speeds X / Y up to 12m/min , Z 6m/min Control electronics are installed in a steel cabinet directly on the machine The connection to the computer is made via EtherCad 2 configurable socket outputs, e.g. suction and vacuum 1 socket via main switch On and Off for control computer of integrated extraction guide, Machine control software "Penta-Tec" with very simple operating functions and many automatic functions, drawing functions, contour calculations, DXF, s4m and G-code import 3D processing, automatic plane and cutter assignment from a DXF leveling probe for height measurement of the table (machine table correction) probe for automatic tool measurement, vacuum table In a cast aluminum plate 15mm "checkerboard pattern" is milled in different areas that can be switched on via ball valve. A 5mm MDF panel is then placed on this table The air is sucked in without drilling the panel ! Equipment of machine: Milling spindle HITECO PT300 L/4/24 SK30 3.8 kW -300 - 24,000 rpm with frequency converter (speed is controlled via the software) -complete collet set Point laser for easier zero point approach. Industrial vacuum cleaner Harmuth Fräse 3x1200 Watt, 80 Liter, 270mbar Notebook PC system for Pentatec control Vacuum pump - Pressure-controlled 4 kW to 100Hz, SV 8.190/2-48 -380 mbar approx. 175 m³/h - Pump control via contact sensor or optionally via vacuum monitoring of the machine speed (with Profi series) - Preselectable vacuum pressure = pump regulates the value as long as the power is sufficient (with vacuum monitoring Profi series) - Price includes all components Tool changer 10-fold - for cone holders, moves pneumatically from the work area so that no travel is restricted and a longer component can be pushed through - incl. control electronics, valves, software extension and safety devices such as: Query of the frequency inverter whether the motor is at a standstill, tool changer open, tool stations free or occupied Taper mounts SK30-ER25 (ER32) for collets from 3 to 16mm (20mm, depending on system) Optical registration mark detection Camera system for detecting registration marks and correcting the milling data (This system is integrated in our software, no second software is installed) Scope of delivery: milling machine + control unit (PC + software), suction cup, compressor, vacuum pump

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing