Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

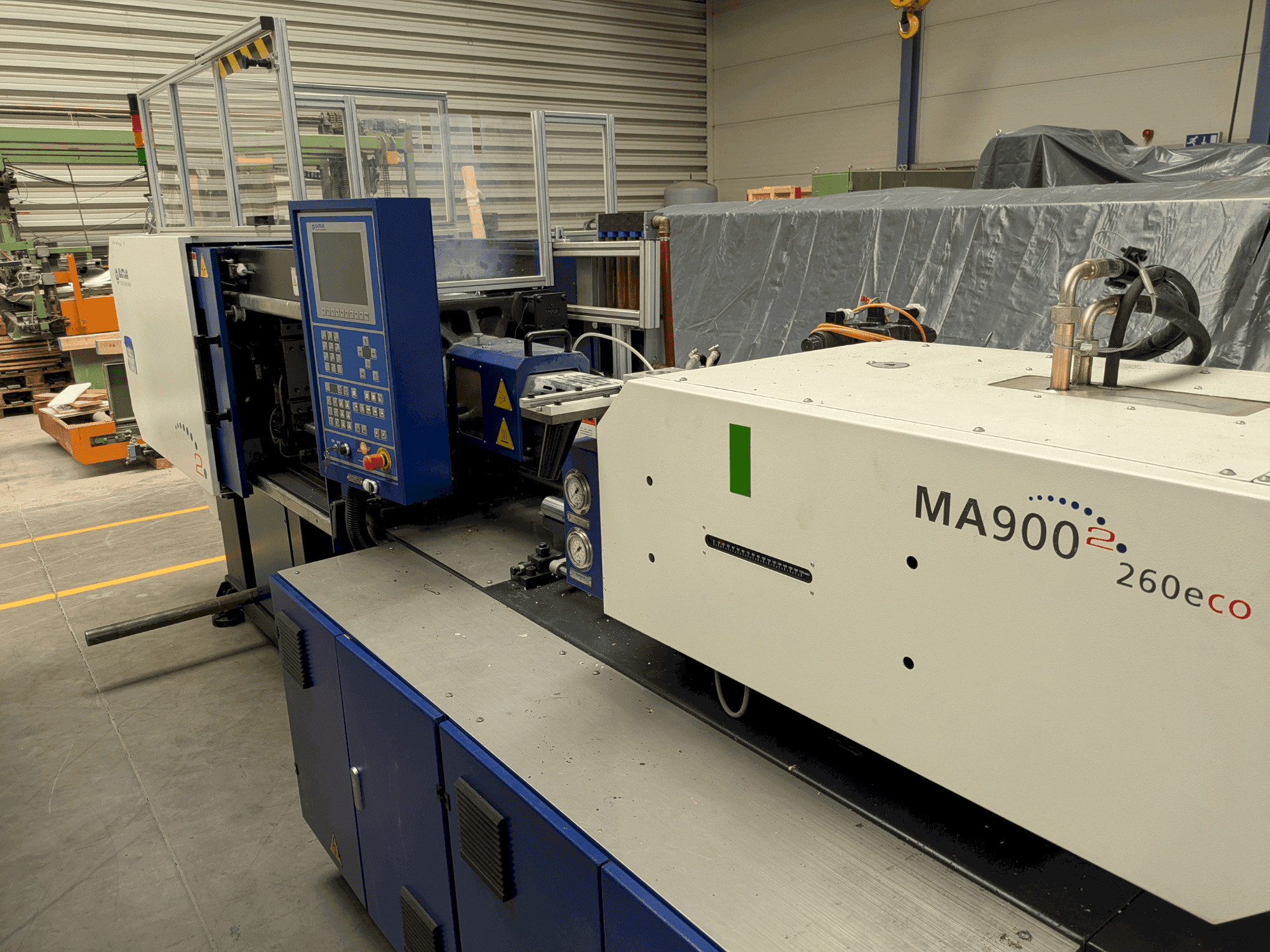

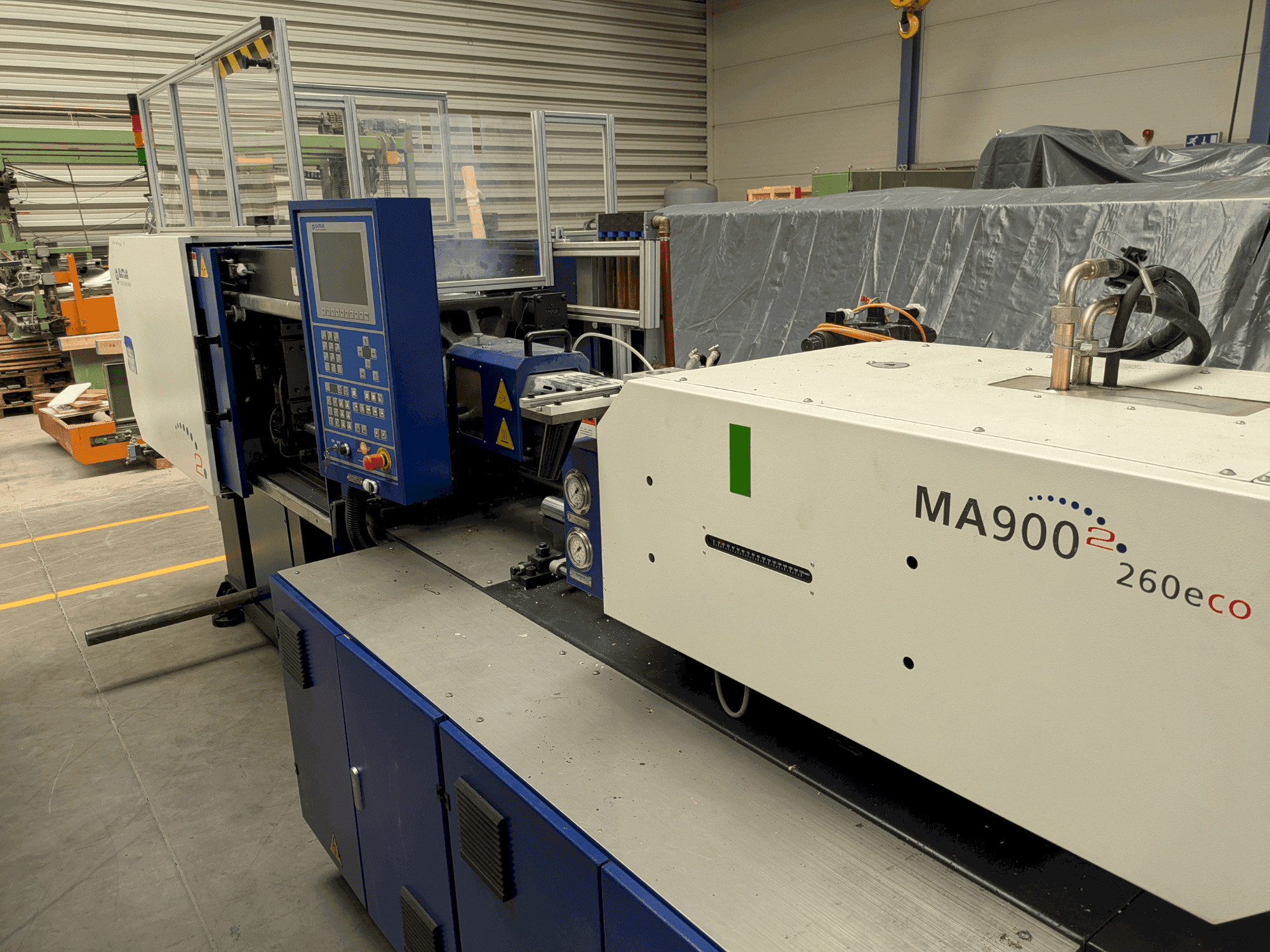

HAITIAN - MA900 II ecoDE-INJ-HAI-2016-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used HAITIAN MA900 II eco For Sale | gindumac.com

This HAITIAN MA900 II eco was manufactured in 2016. It is a hydraulic injection moulding machine with a clamping force of 900kN and a shot volume of 153 cm3. Consider the opportunity to buy this HAITIAN MA900 II eco hydraulic injection moulding machine. Contact us for more information.

Overview

- brand: HAITIAN

- year: 2016

- MODEL: MA900 II eco

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - HAITIAN MA900 II eco

Dimensions

- Machine Depth: 4530 mm

- Machine Height: 1910 mm

- Machine Weight: 3500 kg

Technical Specification

- Clamping Force: 900 kN

- Screw Diameter: 36 mm

Additional Information

Injection Capacity (PS): 139 g

Plasticization Capacity: 13.3 g/s

Heating power: 7. 85 kw

Tie-bar spacing (hxv): 360 × 360 mm

Die-height available: 150 – 380 mm

Ejector number: 5

Pump motor power: 11 kw

Minimum mold size (l×w): 250 × 250 mm

Required Installation Space: Should allow at least 1 m clearance around the machine for operation and maintenance

Machine Foundation & Mat Diagram

Foundation Type: Reinforced concrete foundation recommended.

Load-bearing Capacity: Must support ≥ 3.5 t machine weight.

Level Tolerance: Machine must be installed on a level foundation (≤ 0.2 mm/m slope).

Vibration Damping: Use anti-vibration pads or steel plates under machine feet

Cable & Electrical Requirements

Pump Motor Power: 11 kW

Heating Power: 7.85 kW

Total Installed Power (approx.): ~19 kW

Power Supply: 3-phase, typically 400V / 50Hz (check local spec).

Circuit Breaker Recommendation: ≥ 40 A (depends on local standards).

Grounding: Reliable grounding required (≤ 4 Ω resistance).

Cable Suspension Diagram: Machine must be leveled before connecting cables

Cooling & Hydraulic Requirements

Oil Tank Capacity: 190 L (use recommended hydraulic oil ISO VG46).

Cooling Water Requirement:

For Hydraulic Oil Cooler

For Mold Cooling Circuits (4 × water passages provided)

Water Quality: Clean, non-corrosive, filtered.

Water Pressure: 0.2 – 0.4 MPa

Environmental Conditions

Ambient Temperature: 5 – 40 °C

Relative Humidity: ≤ 90% (non-condensing)

Installation Location: Indoor, vibration-free, dust-free environment

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing