Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

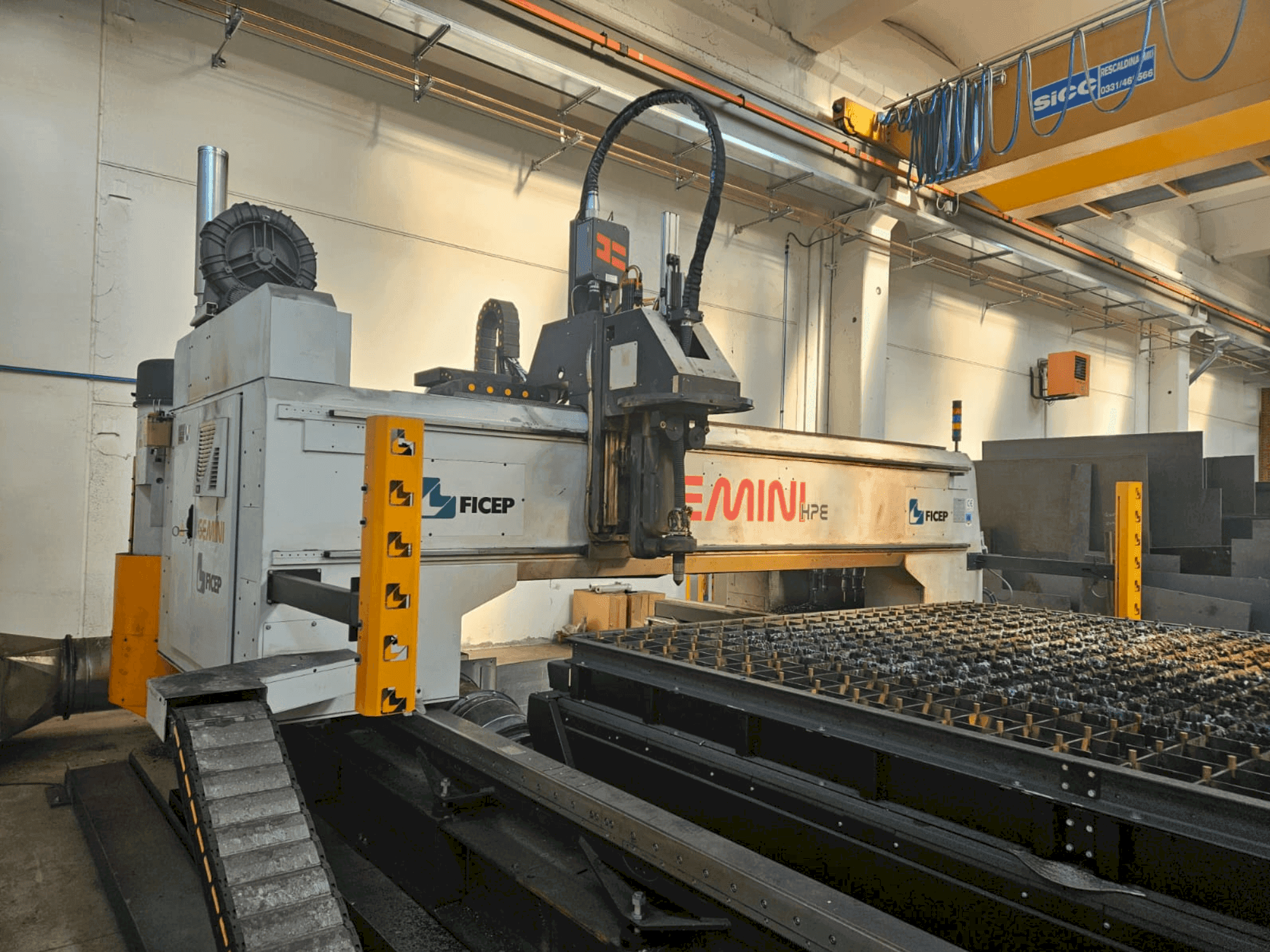

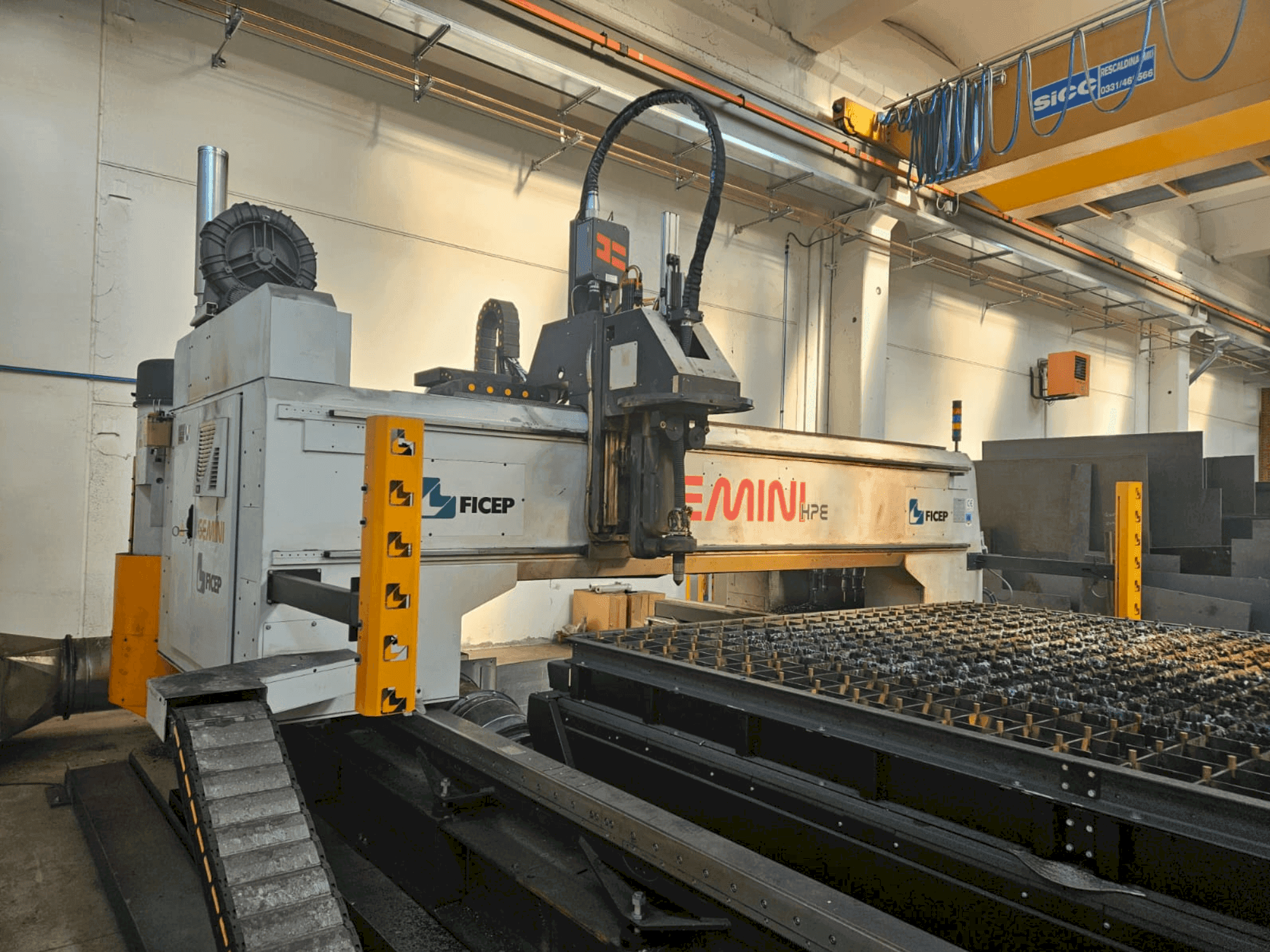

FICEP - GEMINI G32 HPEIT-OTH-FIC-2020-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used FICEP GEMINI G32 HPE For Sale | gindumac.com

This FICEP GEMINI G32 HPE was manufactured in 2020. It is an Automatic Gantry Line for Drilling, Milling, and CNC Thermal Cutting of Large Sheets. Key features include a single-spindle vertical drilling head, an 8-position automatic tool changer, and a high-capacity XPR300 plasma cutting system. Ideal for handling sheets up to 15,000 mm in length and 3,100 mm in width. Contact us for more information about this machine.

Overview

- brand: FICEP

- year: 2020

- MODEL: GEMINI G32 HPE

- application type: Other Sheet Metal Machinery

- Location: Italy

- machine type: Sheet Metal Machine

- control unit brand: FANUC

Technical Information - FICEP GEMINI G32 HPE

Control Unit

- Control Brand: FANUC

- Control Model: Series 30i model B

Additional Information

Machine Benefits

Technical Machine Benefits

- Input sheet specifications: max. Length: 15000 mm / min. Length: 1250 mm / max. Width: 3100 mm / min. Width: 800 mm / output workpiece specifications: min. Length: 100 mm / min. Width: 100 mm

- Vertical drilling head: 1 / spindle for vertical head: 1/ max. Drilling diameter: 40 mm / max. Milling diameter: 250 mm / min. Sheet thickness: 5 mm / max. Drilling thickness: n 5000

- Spindle installed power (s3): 15 kw / spindle speed (programmable, continuously variable): 250 – 7000 rpm / max. Longitudinal travel speed (x-axis): 32 m/min / max. Transverse positioning speed (y-axis): 32 m/min / max. Auxiliary axis positioning speed (u-axis): 42 m/min / working table height: 650 mm

- Motorized torch carriages: 1 / plasma cutting unit: 1 / oxy-fuel torches (optional): 3 / max. Sheet thickness with xpr300 plasma: piercing cut during production: 45 mm / edge-start cut: 80 mm / 45° bevel cut (piercing, production): 32 mm / 45° bevel cut (edge-start): 56 mm / max. Sheet thickness with optional oxy-fuel: 1st torch: 100 mm / 2nd torch: 100 mm / 3rd torch: 75 mm

- Material loading group: loading system for 15 m plates / support bed and rails for 6. 1 m plates / three 3-meter bed extension sections with respective rails / automatic slag discharge system for 15 m bed / machining group: mobile gantry structure with transverse positioning guides / single-spindle vertical drilling head/ transverse carriage / 8-position automatic tool changer for drilling unit / 8 iso 40 tool holders for tool changer / scribing unit / on-board chip suction system / thermal cutting unit: xpr300 plasma cutting system / bevel plasma cutting head (short head) / fume extraction system for sheets up to 15 m / big-bag for fume extractor

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing