Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

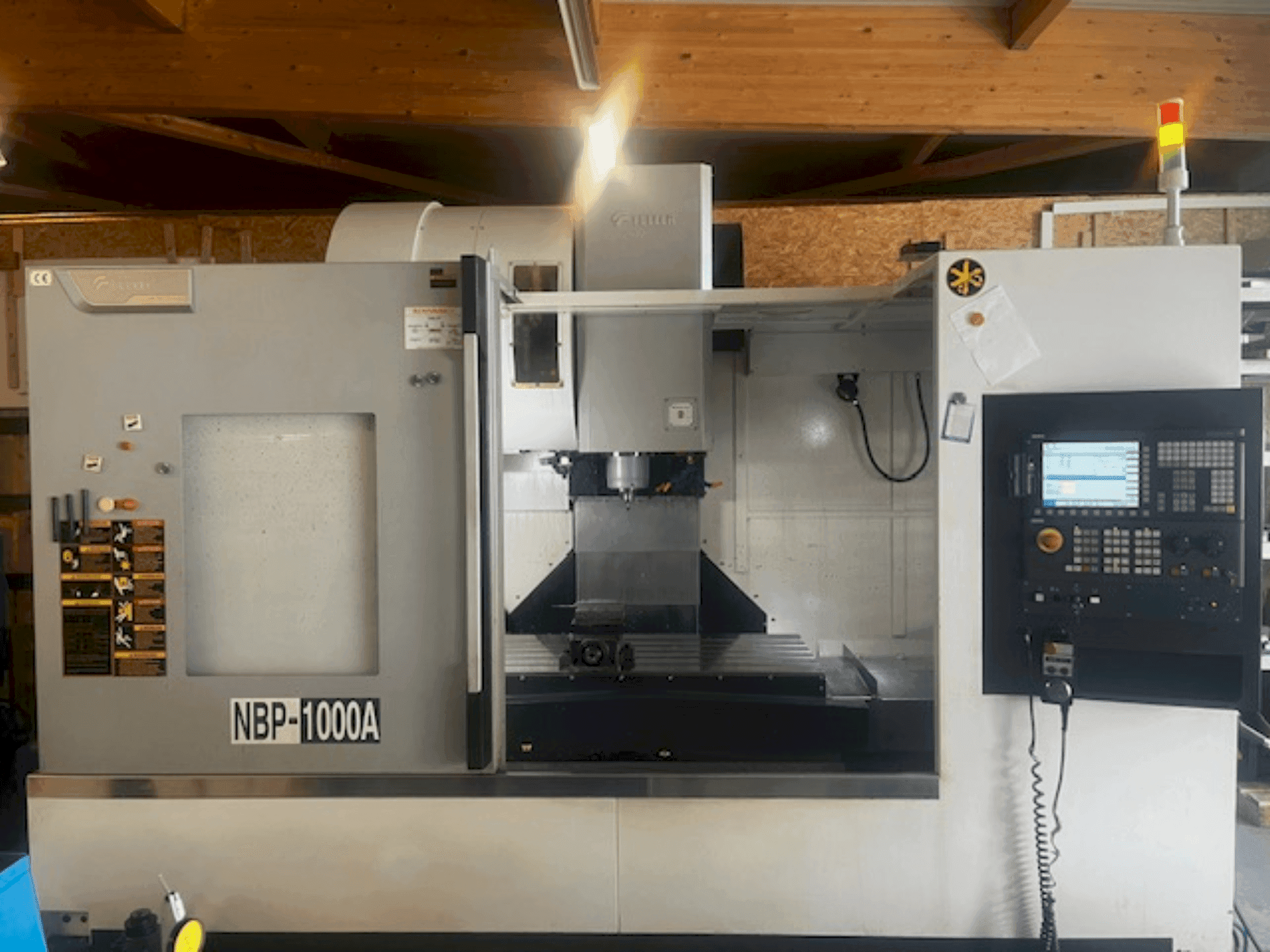

Feeler - NBP 1000ADE-MIL-FEE-2016-00002

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Feeler NBP 1000A For Sale | gindumac.com

This 3-axis Feeler NBP 1000A vertical machining center was manufactured in 2016. It features a robust structure with Meehanite fine-lamella cast iron and heat-treated guideways for superior machining performance. The spindle operates at 10,000 rpm, supported by angular contact ball bearings and a temperature-controlled cooling unit. It includes a 30-station tool magazine with a double-arm changer and a Siemens Sinumerik 828D control system. Consider the opportunity to buy this Feeler NBP 1000A vertical machining center. Contact us for more information.

Overview

- brand: Feeler

- year: 2016

- MODEL: NBP 1000A

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - Feeler NBP 1000A

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik 828D

Movement

- Number of Axes: 3

- X-axis Travel: 1000 mm

- Y-axis Travel: 610 mm

- Z-axis Travel: 600 mm

Technical Specification

- Max. Tool Weight: 8 kg

- Spindle Power: 22.5 kW

- Spindle Speed: 10000 RPM

Additional Information

Additional equipment

- Pump pressure: 30 bar

- Cartridge filter to protect the spindle rotary feedthrough

- Fully enclosed with large doors and maintenance access

- Prepared for oil mist extraction (Ø 200 mm)

- Flushing nozzles on both sides

- Screw/hinge belt conveyor

- Chip bucket included

- Ejector on the left, mounted on the front

Machine Benefits

Qualitative Machine Benefits

- Comissioning was in 2018

Technical Machine Benefits

- Robust, heat-treated spindle (58–62 hrc)

- Temperature-controlled cooling unit for thermal stability

- Front bearings: 4 angular contact ball bearings (Ø 70 mm)

- Rear bearings: 2 angular contact ball bearings (Ø 60 mm)

- Main drive siemens 1ph8133

- Torque: 143 nm at 40% duty cycle (up to 1500 rpm)

Extra Information

Optional expansions: Rotary table preparation: Interface for NC rotary table (without axis module/servo drive) Workpiece measurement: Renishaw OMP60 probe Contact, optical signal transmission Ruby ball Ø 6 mm, length 50 mm IPX8, battery-operated Incl. OMI-2T transmission module Note: Tool holder not included in delivery. Optional: screw compressor. Control Unit SIEMENS Sinumerik 828D 10.4" color LCD User interface: SINUMERIK Operate with ShopMill Guide dimensions: X-axis: Guide width 90 mm, guide spacing 450 mm Y-axis: Guide width 143 mm, guide spacing 1210 mm Z-axis: Guide width 90 mm, guide spacing 450 mm Tools Pull stud: DIN 69872 (SK 40) Tool magazine: 30-station tool magazine Double-arm tool changer, change time: 2.5 s Injection Unit Coolant system: Flood cooling with ring nozzles around the main spindle Pump pressure: 2.5 bar, flow rate: 85 l/min Separate tank: 250 liters Integrated slideway oil return

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing