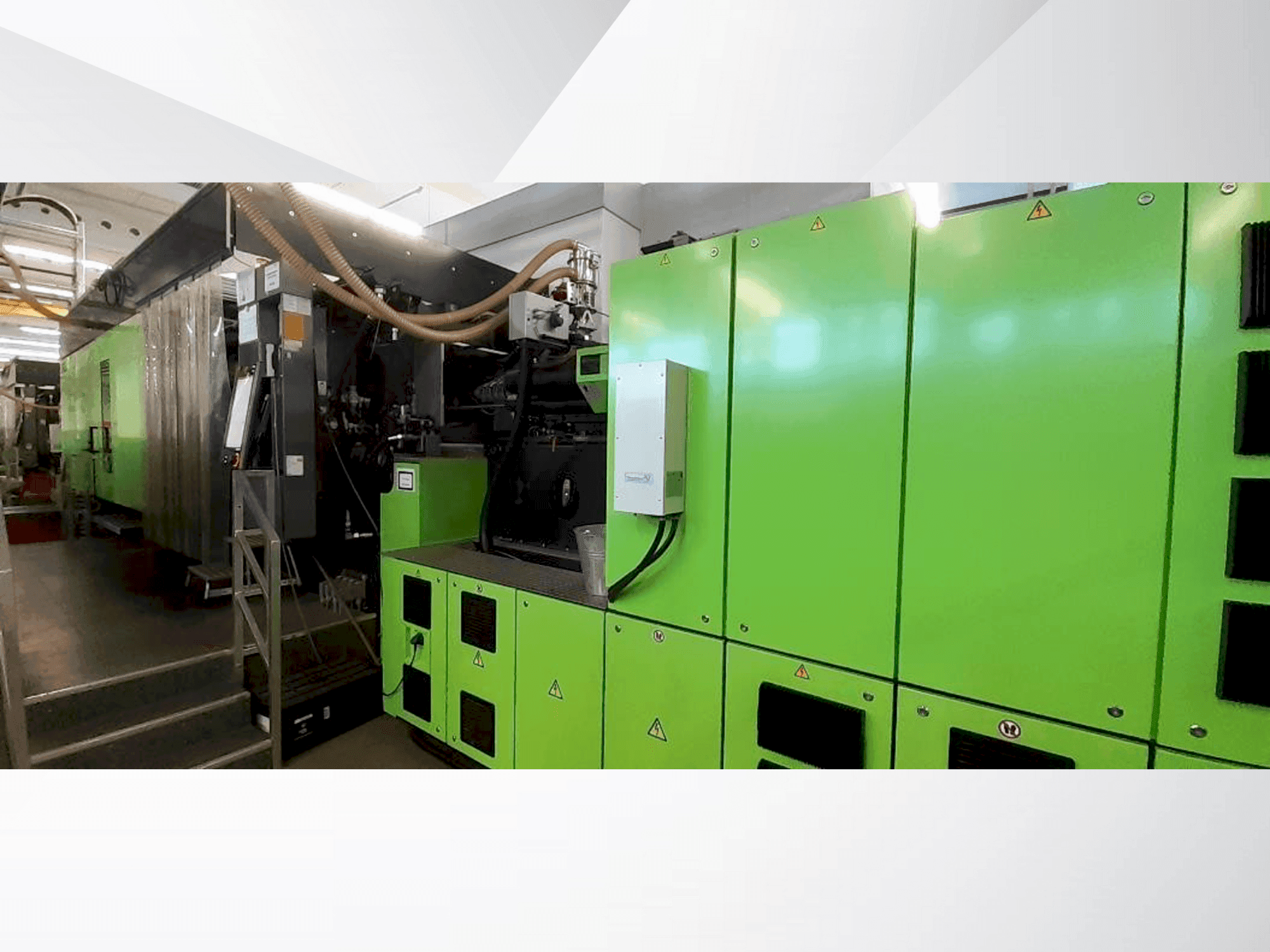

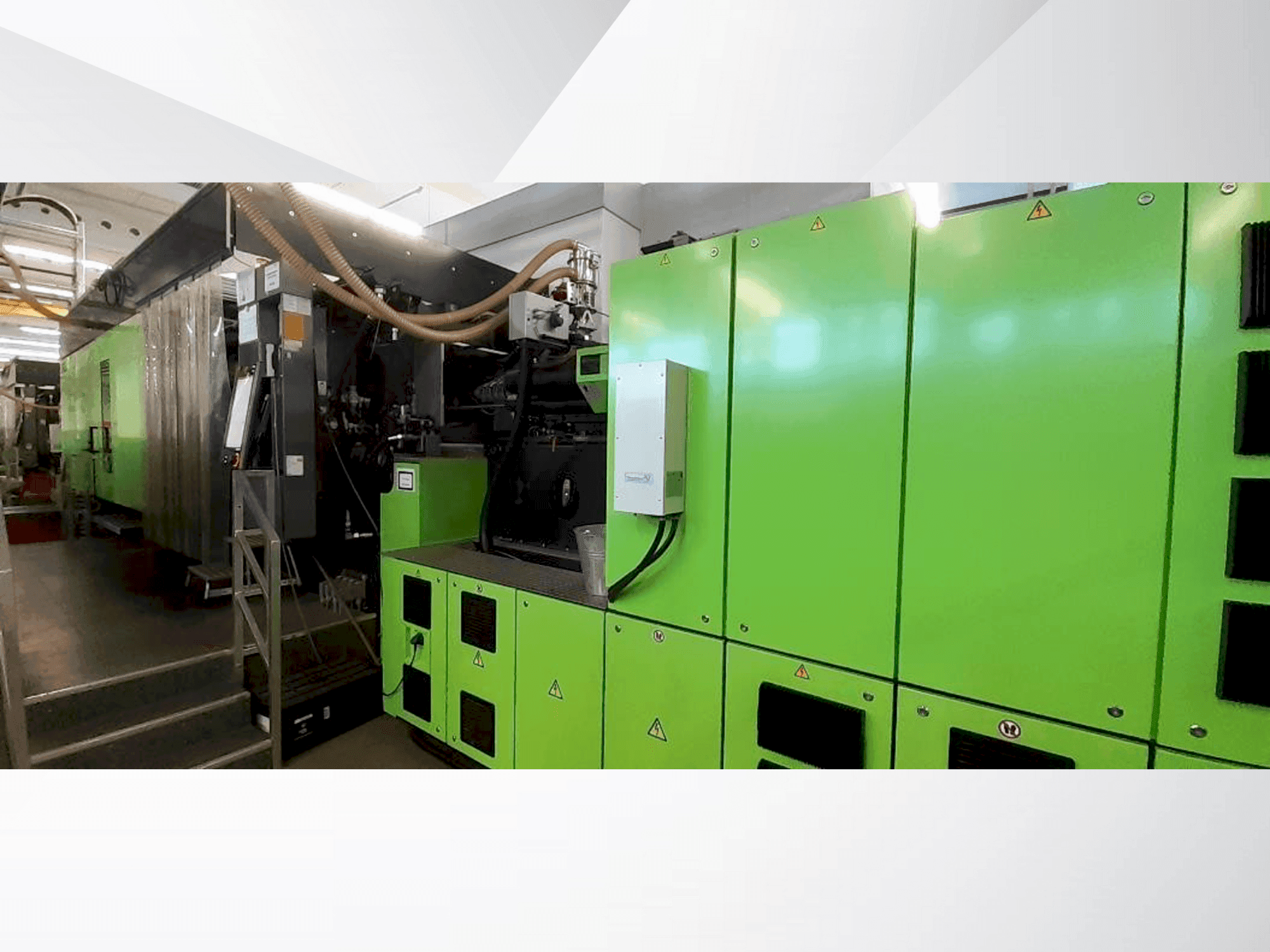

Engel - Duo 740 H / 740 M / 500 WPX combi MDE-INJ-ENG-2019-00003

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Engel Duo 740 H / 740 M / 500 WPX combi M For Sale

This Engel Duo 740 H / 740 M / 500 WPX combi M injection moulding machine was manufactured in 2019. It features a two-plate compact design, minimal footprint, and intelligent servo-hydraulics for reduced energy consumption. The machine includes a CC300 microcomputer control system with a 21.5" full HD touch screen and advanced material package suitable for thermoplastics up to 350°C. For more information about this injection moulding machine, please reach out to us.

Overview

- brand: Engel

- year: 2019

- MODEL: Duo 740 H / 740 M / 500 WPX combi M

- production hours: 14674

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

- control unit brand: ENGEL

Technical Information - Engel Duo 740 H / 740 M / 500 WPX combi M

Control Unit

- Control Brand: ENGEL

- Control Model: CC300 microcomputer

Technical Specification

- Screw Diameter: 45 mm

Additional Information

Additional equipment

- Tool heating: 32 control circuits, max. heating output 60 kW

- Vacuum compressed air circuits: With Venturi nozzle and pressure switch

- Solenoid air valves: 2/2-way, R1/2 inch

- Autoprotect injection monitoring: Self-learning system for mold protection

- Advanced material package: For thermoplastics up to 350°C, max. reinforcement level 30%

Machine Benefits

Qualitative Machine Benefits

- High precision and sensitive mold protection

- Advanced control system with a 21. 5" full hd touch screen and user authorization system

Technical Machine Benefits

- Platen stroke: 1800 mm

- Max. Platen distance: 2650 mm

- Mold installation height: min. 850 mm, max. 1740 mm

- High operational reliability with stable platen guidance and precise platen parallelism

- Energy-efficient with reduced energy consumption and intelligent servo-hydraulics (engel ecodrive)

- Multi-circuit hydraulics enabling parallel movements (ejector, core pull, nozzle)

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing