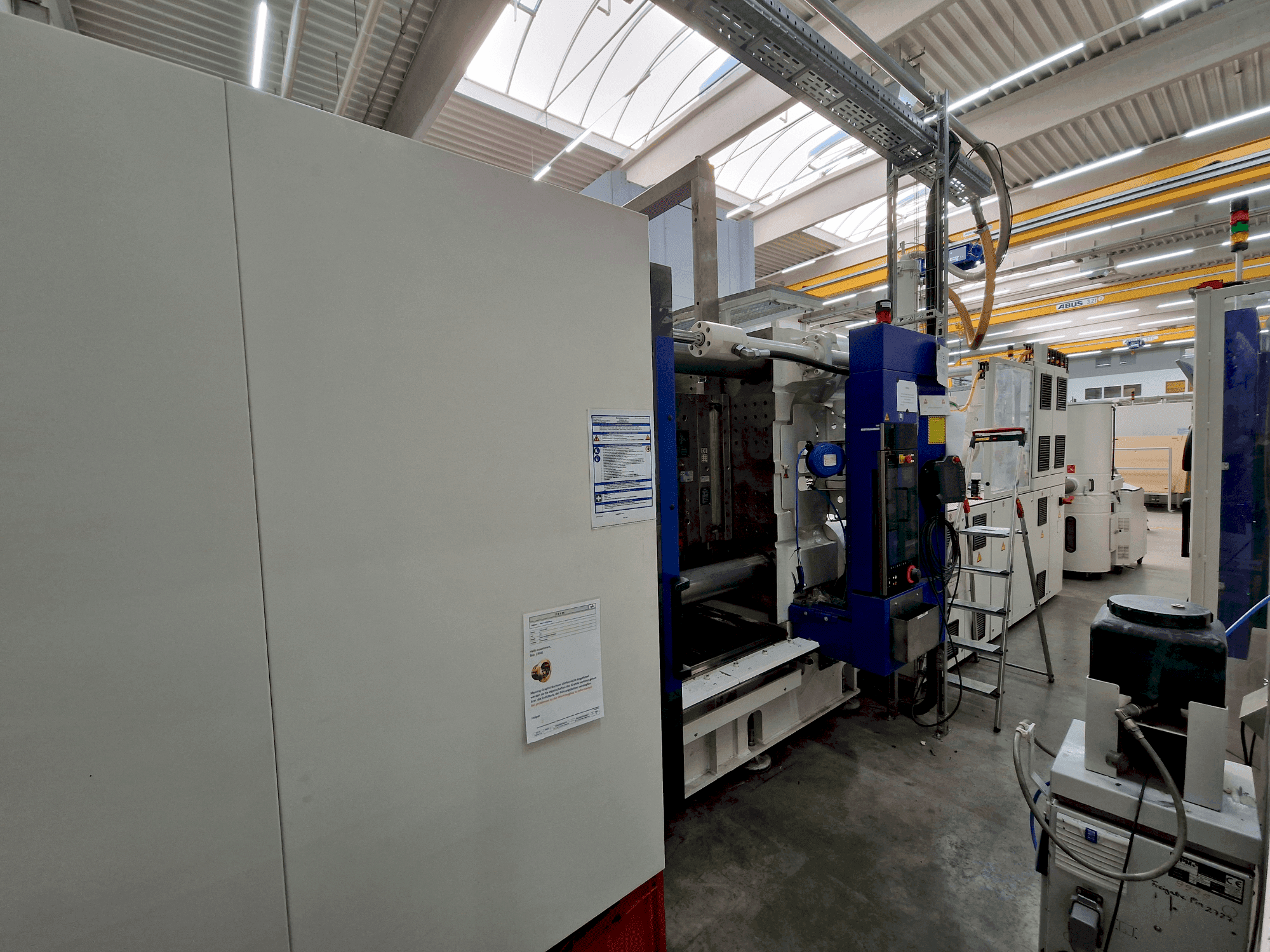

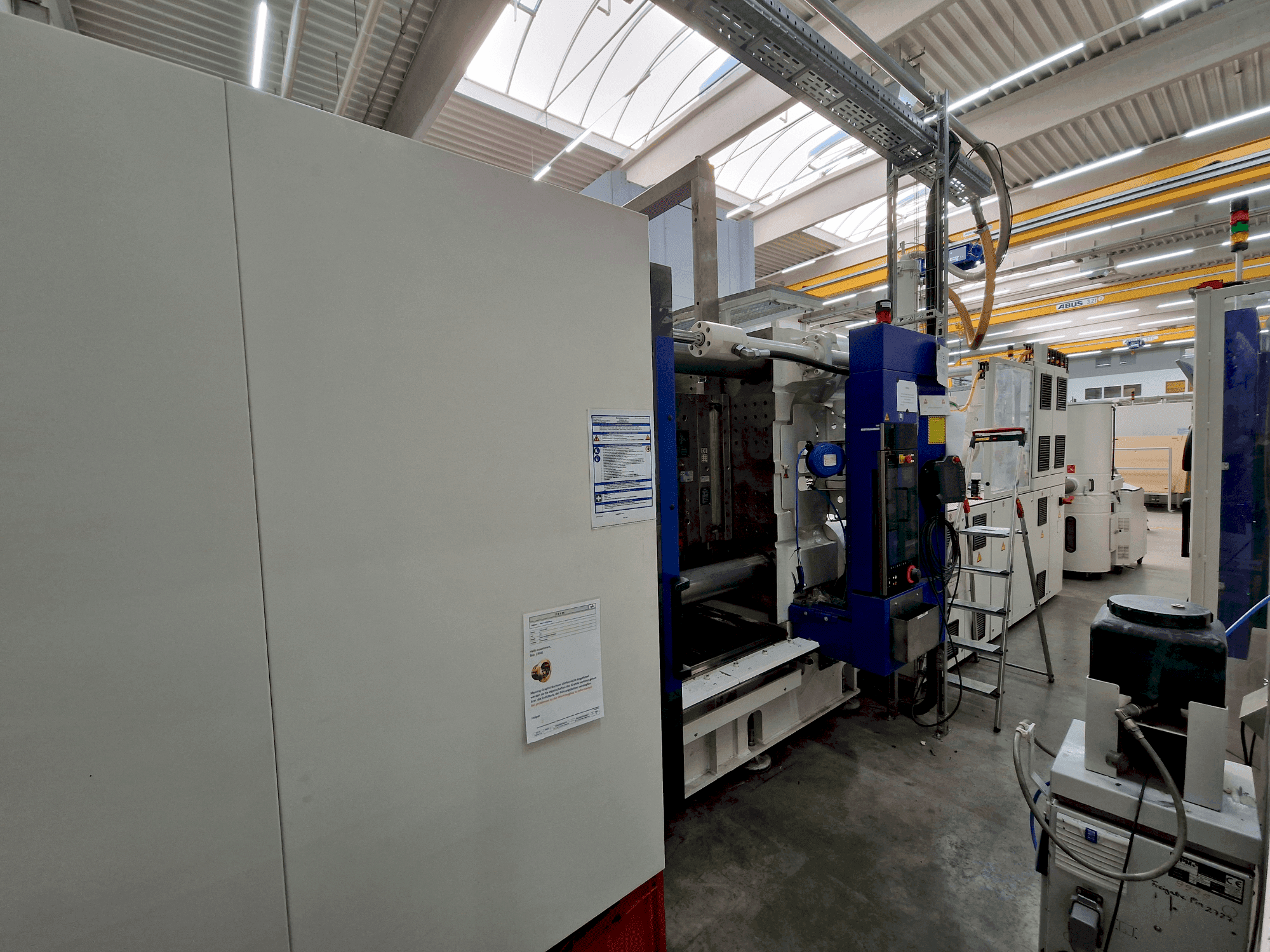

Engel - duo 2400/650DE-INJ-ENG-2019-00004

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Engel duo 2400/650 For Sale | gindumac.com

This Engel duo 2400/650 electrical injection moulding machine was manufactured in 2019. It features a screw diameter of 60/70/80 mm, a screw stroke of 315 mm, and a maximum injection capacity of 890 cm³. The clamping force reaches up to 6500 kN with a maximum mold weight of 11000 kg. Consider the opportunity to buy this Engel duo 2400/650 electrical injection moulding machine. Contact us for more information about this machine.

Overview

- brand: Engel

- year: 2019

- MODEL: duo 2400/650

- application type: Injection Moulding

- Location: Germany

- machine type: Electrical Injection Moulding Machine

- control unit brand: ENGEL

Technical Information - Engel duo 2400/650

Control Unit

- Control Brand: ENGEL

Dimensions

- Machine Weight: 6500 kg

Technical Specification

- Clamping Force: 6500 kN

- Screw Diameter: 60 mm

Additional Information

Additional equipment

Oil Reservoir Capacity - Injection Unit: 500 l

Maximum Cooling Power (32°C Water Inlet): 29.40 kWcool

Water Consumption (32°C): 4.80 m3/h

Machine Benefits

Qualitative Machine Benefits

The machine has electric water batteries (4 e-flomos with 8 circuits each).

The injection units are fitted with accumulators which enable a high injection pressure of up to 2400 bar with a 60 mm screw.

Technical Machine Benefits

Maximum injection capacity: 890 cm³

Screw torque: 2000 nm // maximum screw speed @ reduced torque: 275 min-1

Reduced torque @ maximum screw speed: 1600 nm

Recovery rate (3-zone screw): 51 g/s // recovery rate (barrier screw): 67. 1 g/s

Injection rate: 353 cm³/s

Nozzle stroke: 950 mm

Ld ratio: 24. 0

Heating zones incl. Nozzle: 8 // heating wattage: 27. 5 kwel

Opening force with pressure pad: 510 kn

Maximum distance between platens: 1750 mm

Extra Information

Dimensions & Weight

Drop Out Chute Width: 1100 mm

Weight of Clamping Unit: 20,000 kg

Maximum Mold Weight (Moving Platen): 7,330 kg

Maximum Mold Weight (Stationary Platen): 7,330 kg

Maximum Mold Weight (Total): 11,000 kg

Cycle Data (Euromap 6)

Stroke: 700 mm

Dry Cycle Time: 2.9 s

Control System: Monocompute CC300

Main Features

21.5” full HD touchscreen

USB interface / Ethernet connection

E-move control element

3 keycards for user login

Graphic symbols for cycle control

Screen languages: German, English

Acoustic error signal / Signal light for error display

Programs & Monitoring

Power Control: optimizes motor performance during dispensing

Mould parallelism measurement

IQ Weight Monitor: monitors shot weight & viscosity

IQ Weight Control: automatic injection parameter adjustment during fluctuations

Quality monitoring interface (injection time, dosing time, pressure, cycle time)

Continuous ejection possible when monitoring is deactivated

Clamping Unit & Plates

Reinforced clamping plates (FAP & BAP +50 mm each)

Reduced min./max. tool height and panel distance (–100 mm due to reinforcement)

FAP: smallest possible platen opening, spherical calotte minimized

BAP: without ejector opening

Additional threads according to EUROMAP VOL1

Centering grooves according to drawing

Plate ejector – Variant A (adapted to clamping pattern)

Safety interface for ejector

Hydraulics & Core Pulls

Hydraulic core pull:

1-fold on moving platen

2-fold on fixed platen

2-fold on moving platen with PQ proportional valve, volume measurement, pressure/speed adjustment

Interface for intermediate core pull position

Mold Heating & Cooling

Mold heating: 16 circuits, max. 40 kW heat output (Euromap 14)

Temperature monitoring interface (moving & fixed platen)

4-fold hydraulic mold nozzle control

Separate cooling water connection (tool & machine)

Temperature control unit interface: Engel protocol, 20 mA current loop

4-way flow regulator (0–10 l/min)

Hose specification: max. 90 °C / 4 bar

Hoses for mold cooling

4 temperature control circuits at rear of machine

Rinsing nozzle with hose clamp

2× ENGEL e-formo temperature control systems (1–15 l/min, 8 circuits, max. 120 °C)

1 distributor for fixed plate, 1 for movable plate

Additional e-formo unit on operating side (optional)

Drive & Hydraulics

ENGEL ecodrive S+V3 (speed-controlled servo drive)

Closed control system for pressure & speed (closed loop)

2× 50 L hydraulic accumulators (for spraying process)

Battery position at the front (as per drawing)

Oil cooler (standard capacity)

Supplied without oil filling (oil contains zinc during commissioning)

Quiet, energy-efficient hydraulics with optimized control, filtration, oil preheating & cooling

Injection Unit

Bi-metallic cylinder (Fe-based), abrasion & corrosion resistant, up to 350 °C

Additional zone heating on barrel

Thrust washer (diaphragm) for screw S8, Ø 60 mm, L/D 24, geometry G1

UNR9 RGB non-return valve (powder metallurgical chrome steel)

Corrosion-resistant flange

Special open nozzle, corrosion-resistant, flange thread V445x3, radius 15 mm, bore 8 mm

Nozzle outlet suitable for hot runner connection

230 V cylinder & nozzle heating

Ceramic cylinder covers

Insulated heating areas (not suitable for PC, PMMA, PVC, etc.)

Electrical System

Supply voltage: 3×400 V + N + PE / 50 Hz

Schuko sockets (230 V), max. 2 pcs

3-phase CEE socket (10/16 A)

Potential-free contacts: 4 inputs / 4 outputs (freely programmable)

Interfaces (Euromap)

13 – Core pull end positions

14 – Heating

63 – Online data access

65 – Tank calculation

Robot & Accessories

ENGEL easix robot (KR 60, special version)

Robot control unit not integrated multiple times

Assembly & test at ENGEL

Operating instructions: printed + CD (German)

Compliance, Design & Extras

EN 201 conformity (machine safety)

Paint finish: RAL 9002 (gray-white) & RAL 5002 (ultramarine blue), special ENGEL design

E-connect.24 basic package (remote maintenance)

Machine feet (standard version)

Labeling in German

All 4 E-Flomo units completely renewed by ENGEL

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing