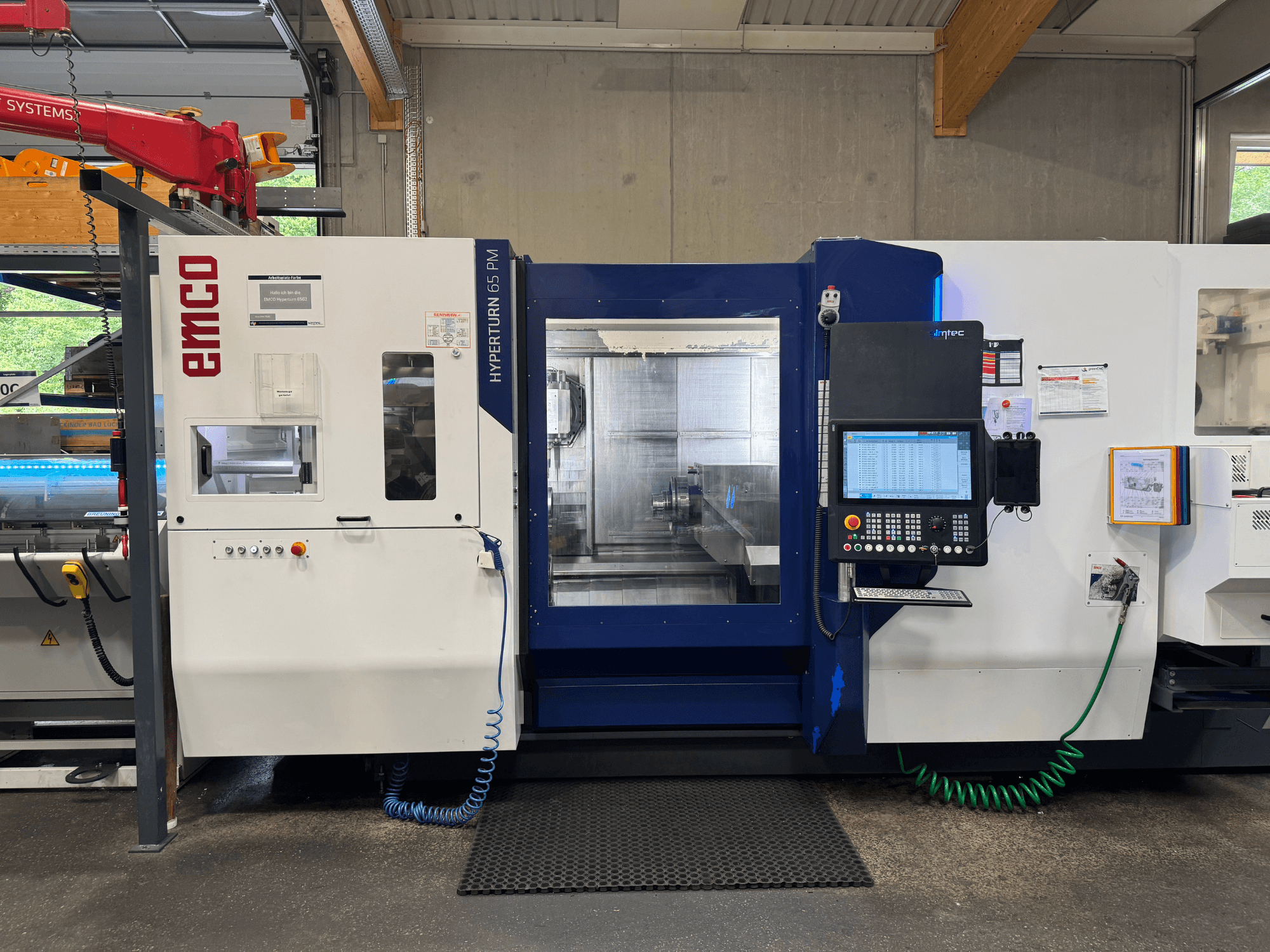

EMCO - Hyperturn 65 Powermill G2AT-TUR-EMC-2022-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used EMCO Hyperturn 65 Powermill G2 | Turn-Mill Centre

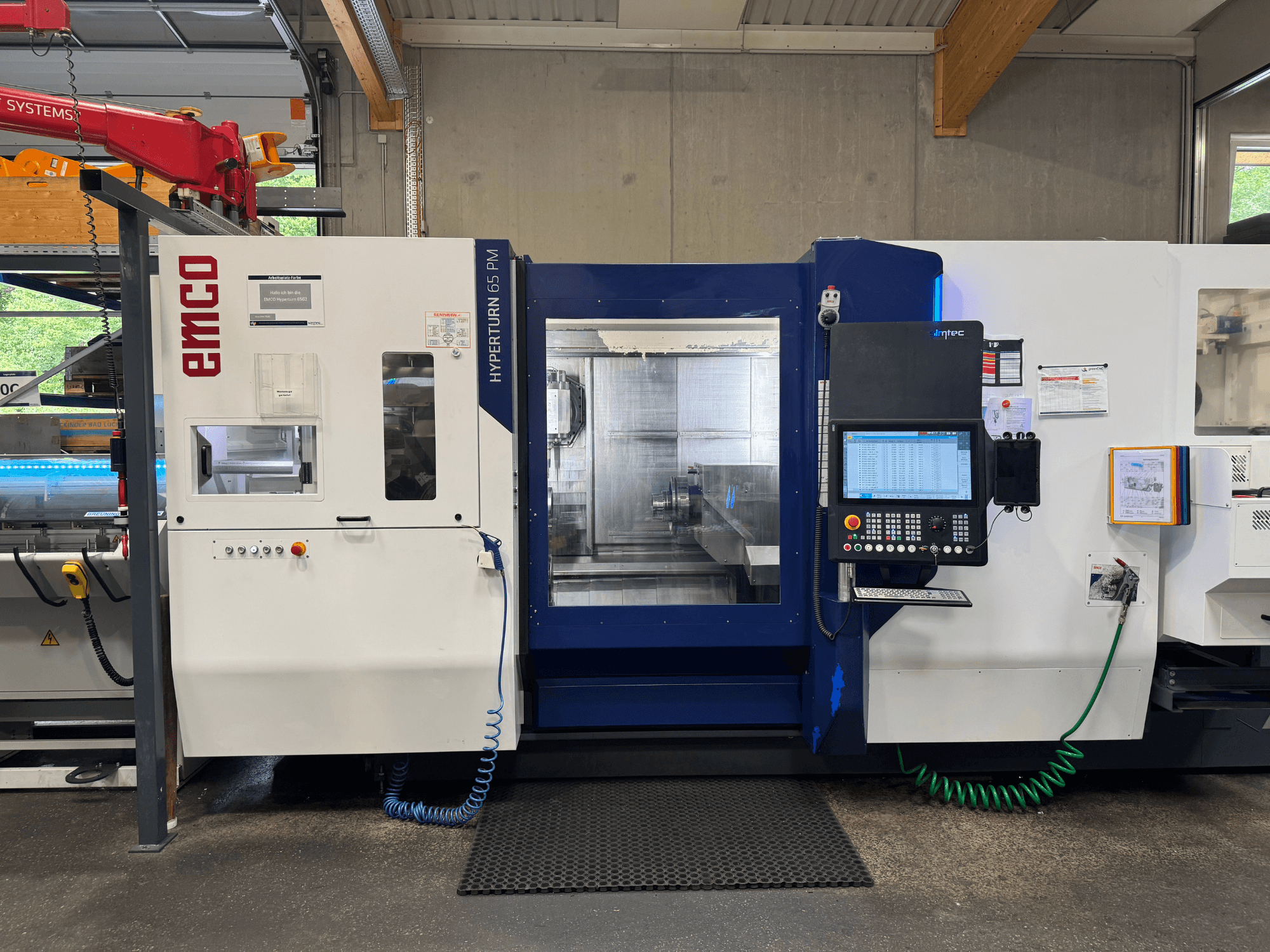

This 6-axis EMCO Hyperturn 65 Powermill G2 was manufactured in 2022. A highly productive CNC turn-mill center, it features a main spindle and subspindle both with a max torque of 250 Nm and speeds up to 5000 rpm. The milling spindle offers up to 12000 rpm. Includes a 40-position tool magazine, 12-position turret, and advanced Sinumerik ONE control system. If you are looking to get high-quality turning and milling capabilities consider the EMCO Hyperturn 65 Powermill G2 machine we have for sale. Contact us for more information.

Overview

- brand: EMCO

- year: 2022

- MODEL: Hyperturn 65 Powermill G2

- application type: Turning

- Location: Austria

- machine type: Turn-Mill Centre

Technical Information - EMCO Hyperturn 65 Powermill G2

Dimensions

- Machine Weight: 620 kg

Movement

- Number of Axes: 6

Technical Specification

- Spindle Power: 29 kW

- Spindle Speed: 5000 RPM

Additional Information

Main spindle (direct drive):

Max. torque: 250 Nm

Subspindle (direct drive):

Max. drive power: 29 kN (as provided)

Max. torque: 250 Nm

Speed range: 0–5000 rpm

Milling spindle (direct drive):

Max. drive power: 37 kW

Max. torque: 30 Nm

Speed range: 0–12000 rpm

Tool turret (direct drive):

Max. drive power: 10 kW

Max. torque: 30 Nm

Speed range: 0–12000 rpm

Kinematics and axes:

Cross slide at the top with turning/milling spindle as motor spindle; hydraulic clamping during turning

Y-axis travel: +/- 120 mm

B-axis with direct drive: +/- 120°, hydraulic clamping

Tooling:

40-position tool magazine, HSK-T63

12-position radial turret with direct drive, BMT55P tool interface

Spindles and clamping:

High-clamping cylinder with draw tube for main spindle

Full clamping cylinder with partial hollow clamping 66 x 550 mm deep in counter spindle

Programmable clamping pressure for main and counter spindle

External feed flushing on main and counter spindle

Mechanical holding brake on main and counter spindle

C-axis for main and counter spindle

Control and HMI:

SINUMERIK ONE / OPERATE, EMCONNECT app-based UI

22" multi-touch display

IPC with 240 GB

SHOPTURN dialog programming

3D simulation and Drawing

Residual material detection

Unblocking from external memory

CAD reader (DXF import)

TRANSMIT and TRACYL for C-axis programming

USB interface, Network drive (Ethernet)

PC keyboard incl. HMI hotkey

LED status bar

Fluids and utilities:

2 coolant lines at 25 bar

2 flushing pumps at 4.3 bar

Control cabinet air conditioning unit

Cooling system for spindle motors, milling spindle, B-axis torque motor, and turret direct drive

Hydraulic unit

Machine light

8 leveling elements

Feedback/measurement:

Glass scales: X1 (incl. air system), Y1, Z1, X2 (HT65-PM-G2 / 840D-sl)

Additional equipment

Chip management and filtration:

Hinged belt chip conveyor, discharge height 1200 mm

Belt filter system, 980 liters

Dirty water pump

Control/monitoring options:

BAOD-SL electronic handwheel (portable, magnetic mount for Siemens controllers)

EMCO tool breakage and wear monitoring / B40D-SL

Wireless probe / HSK drill breakage control BK-MICRO

4-axis turning / balance cutting (SINUMERIK option)

Alternative-end spindle speed (SINUMERIK option)

Turret as tailstock (SINUMERIK option)

Counter spindle as tailstock (SINUMERIK option)

Bar feeder (specifications as provided):

Bar length: 300–1200 mm

Bar diameter: 10–104 mm

Material support surface (front view): 800 x 1250 mm

Material capacity: 12 bars with 65 mm diameter

Max. load capacity: 400 kg (max. 74 kg/bar)

Rectangular material: min. edge length 6 mm; max. circumference 105 mm

Hexagonal material: SW 5 to 85 mm

Round material: <15 mm

Push rod retraction depth: 1470 mm

Power supply: 24 V DC (interface)

Dimensions: length 1800 mm; width 1315 mm

Slide/spindle height: 1090–1330 mm

Weight: approx. 620 kg

Zubehör:

Spannfutter, Hainbuch Centrotex M Schnell Wechselsystem.

Axzug SE100

Axzug SE65

Axfix SE 65

Axfix SE100

Span Dorn T210 GR0

4 Bachen Futter INOFlex® VT-S 016 ( 160 futter)

Warenwert ca.: 70.000€

Sowie BMT 55 Halter Unten

Und 40Hsk Aufnahmen ( Warenwert ca.: 30.000)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing