Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

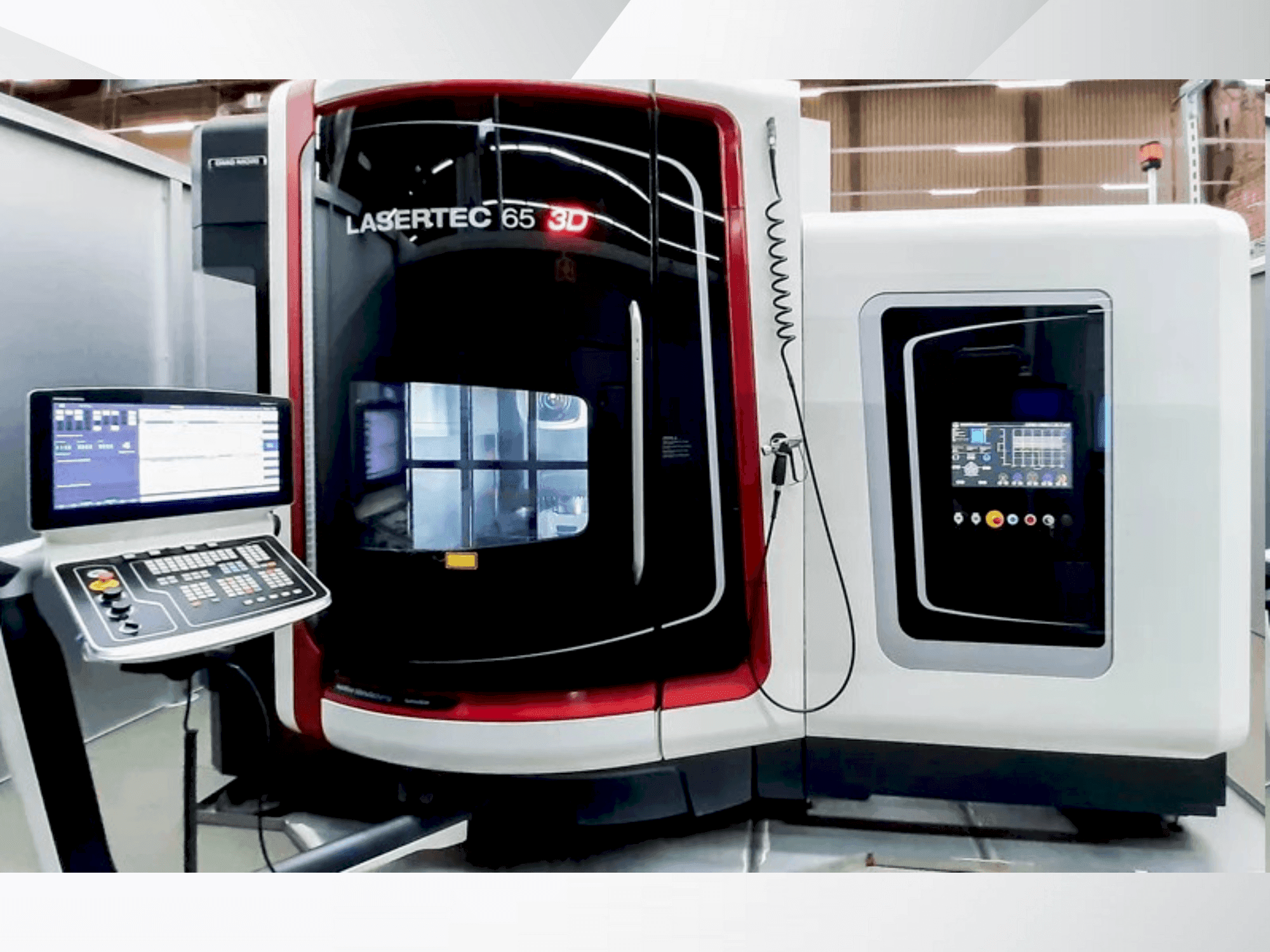

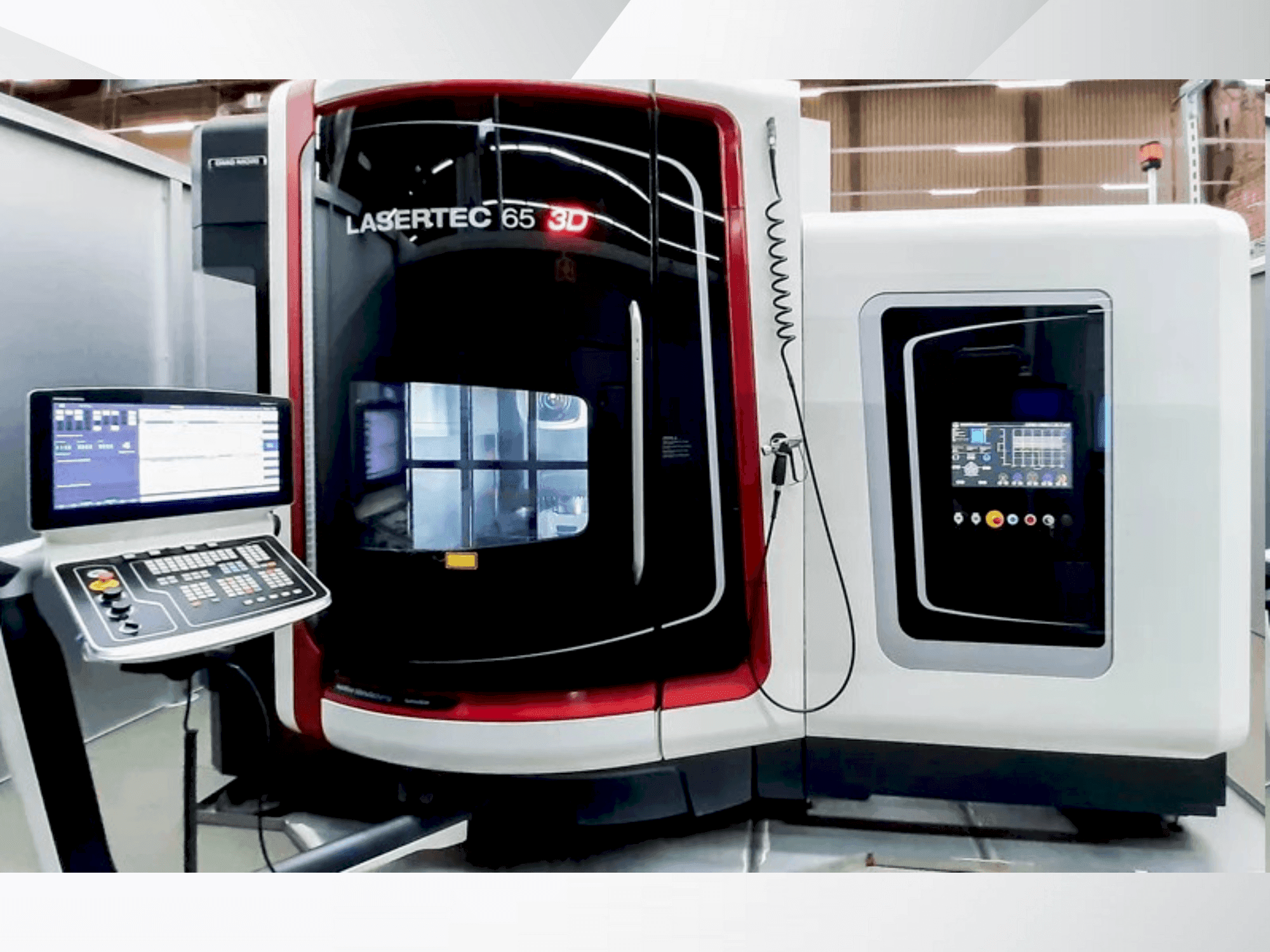

DMG MORI - Lasertec 65 3DDE-MIL-DMG-2016-00004

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG MORI Lasertec 65 3D Sale | gindumac.com

This 5-axis DMG MORI Lasertec 65 3D universal machining centre was manufactured in 2016. It features a motorized spindle with a speed of 1,000 rpm, a HSK-A 63 tool holder, and a 30-position kettle magazine. The NC swivelling rotary table supports milling and turning with a permissible load of 600 kg. Additional features include a link belt chip conveyor with a 600-liter coolant system and an external coolant supply. For more information about this universal machining centre, please reach out to us.

Overview

- brand: DMG MORI

- year: 2016

- MODEL: Lasertec 65 3D

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: SIEMENS

Technical Information - DMG MORI Lasertec 65 3D

Control Unit

- Control Brand: SIEMENS

- Control Model: 840D sl FD Operate

Movement

- Number of Axes: 5

- X-axis Travel: 735 mm

- Y-axis Travel: 650 mm

- Z-axis Travel: 560 mm

Technical Specification

- Spindle Speed: 1000 RPM

- Through-spindle Coolant: Yes

Additional Information

Additional equipment

- 2 X laser safety windows (double window)

- CELOS® with Siemens 840D sl FD Operate including 21.5 ERGOline® Control

- Paper belt filter

- Energy measuring device for CELOS

- the laser hours are 3017h switch-on hours of the unit and 401h productive hours, i.e. laser on.

- Machine has 12,829h switch-on hours and 6,469h productive hours, program run.

Machine Benefits

Qualitative Machine Benefits

- Chip flushing in work area door

- Flushing gun with pump

- Oil and emulsion mist separator

- Blast air through spindle centre

- 3d path control

- Nc swivelling rotary table: milling & turning

- Infrared measuring probe: renishaw pp60 optical (omp 60)

- Combined tool measurement in the work area: blum laser 3d quickset

- Electronic handwheel

- Deckel maho mdynamic package

Technical Machine Benefits

- Cooling pressure: 40 bar

- Kettle magazine: 30 magazine positions hsk-a 63

- Chip tray with integrated coolant tank: 5001

- Table top c-axis: d 680 mm

- C-axis speed: 1000 rpm

- Permissible load: 600 kg

- Link belt chip conveyor with coolant system: 600 litres

- Discharge height: 950 mm

- Width: 670 mm

- External coolant supply: 4 bar / 40 l/min

Extra Information

Machine still under power / OEV was 1,1 Million Euro / 1,1 Millionen Neupreis - / Machine was technically retrofitted to state of the art 5

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing