Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

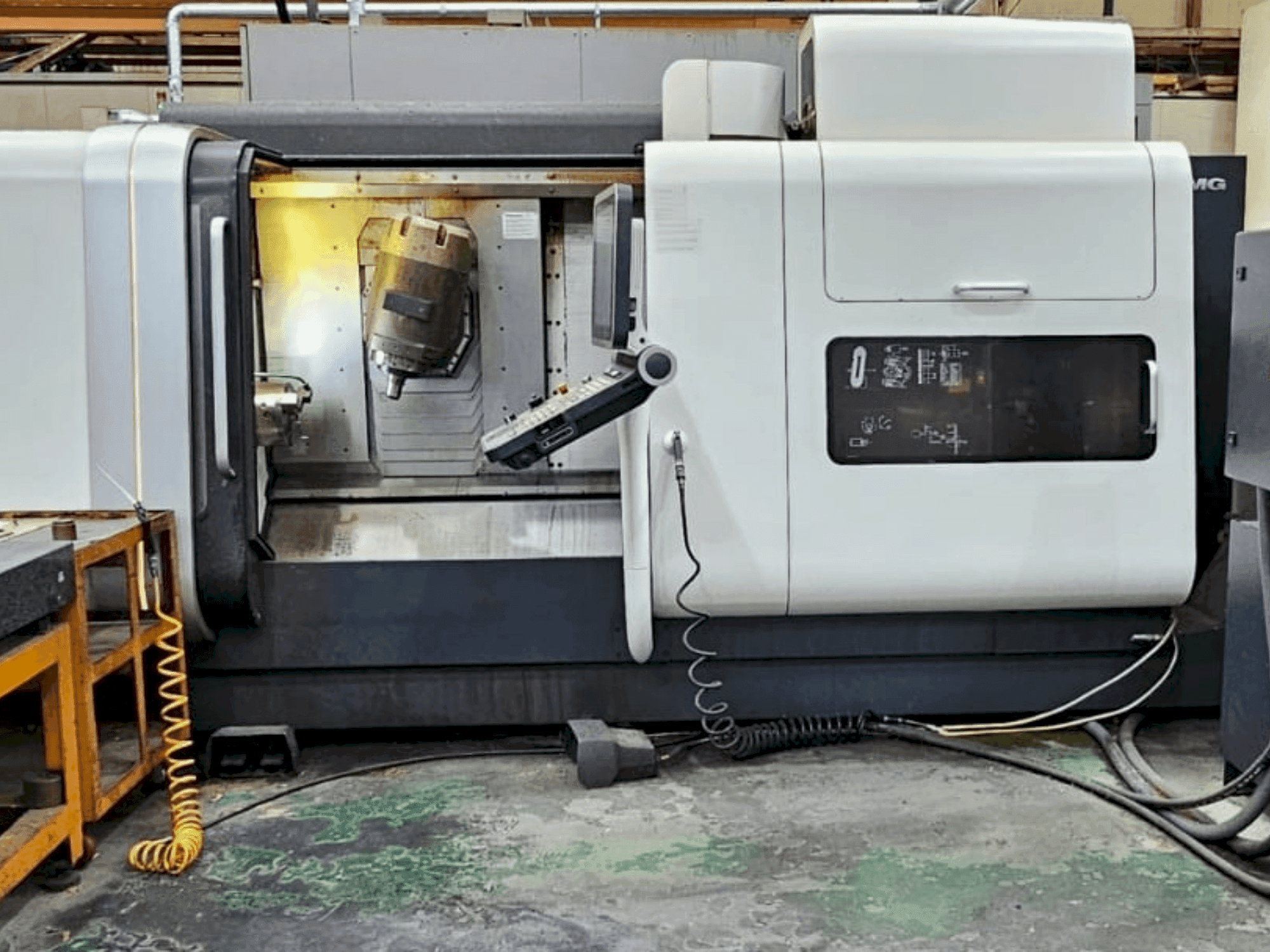

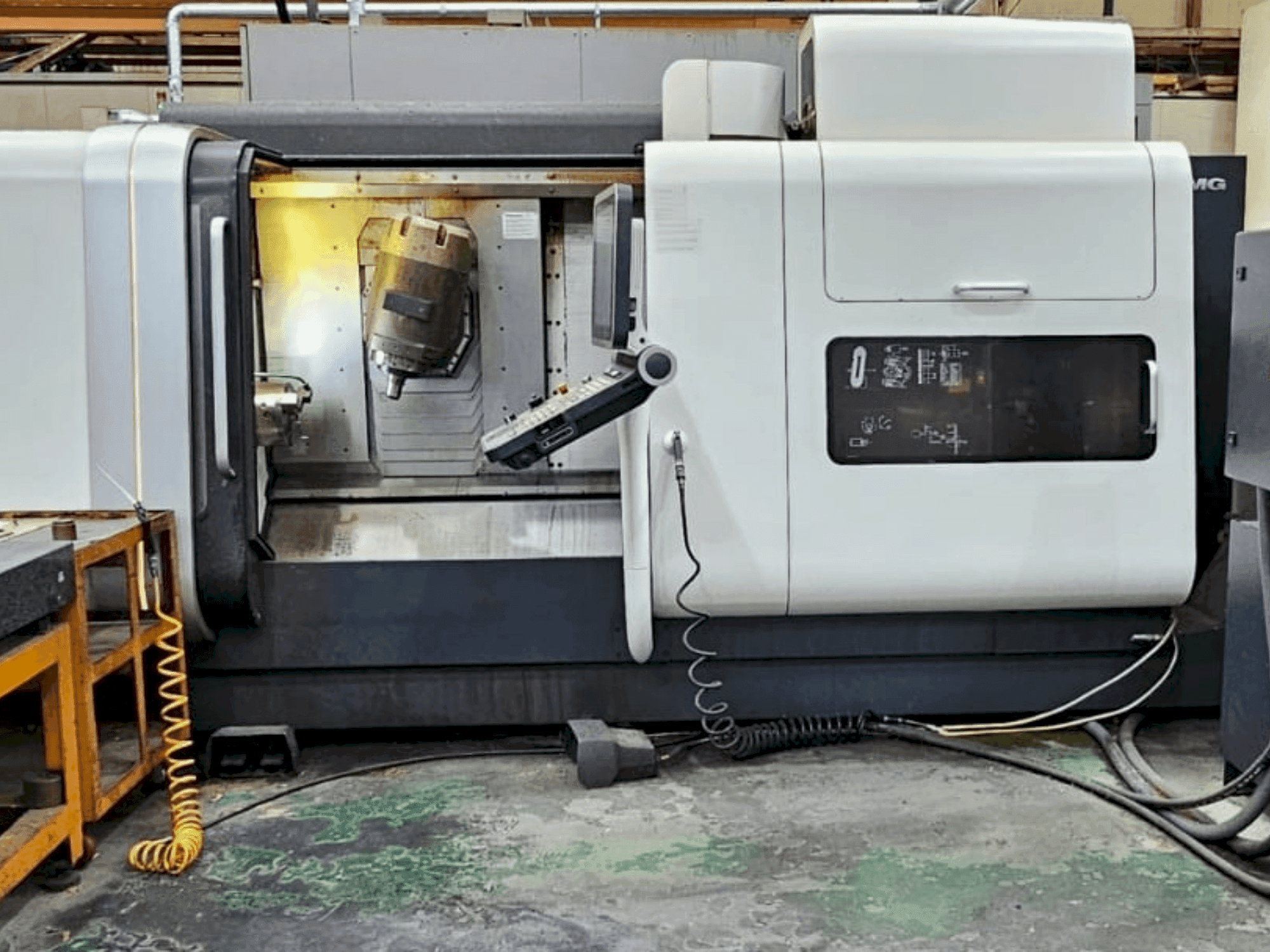

DMG MORI - CTX 1250 TCSG-TUR-DMG-2012-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG MORI CTX 1250 TC For Sale | gindumac.com

This 5-axis DMG MORI CTX 1250 TC was manufactured in 2012. It features a Siemens 840D control, integrated spindle motors with speeds up to 5000rpm, and a 48-tool magazine. Capabilities include Y-axis movement of +/- 100mm, B-axis rotation of +/- 110 degrees, and gear hobbing. It also has a chip conveyor and a cooling system with a paper filter. If you are looking to get high-quality turn-mill capabilities, consider the DMG MORI CTX 1250 TC machine we have for sale. Contact us for more information.

Overview

- brand: DMG MORI

- year: 2012

- MODEL: CTX 1250 TC

- production hours: 33982

- application type: Turning

- Location: Singapore

- machine type: Turn-Mill Centre

- control unit brand: SIEMENS

Technical Information - DMG MORI CTX 1250 TC

Control Unit

- Control Brand: SIEMENS

- Control Model: 840D

Dimensions

- Machine Weight: 9800 kg

Movement

- Number of Axes: 5

- Y-axis Travel: 100 mm

Technical Specification

- Spindle Power: 25 kW

- Spindle Speed: 5000 RPM

Additional Information

Additional equipment

- C Axis and Spindle Brake

- Turn/Mill Spindle with Hydraulic Brake on Turning, HSK-63A – 12000 rpm

- Excentric Turning & Milling Operation

- Tooth System via Gear Hobbing

- Direct Measuring System X, Y & Z Axis

- Cooling System with Paper Filter // Coolant Through Spindle and Pneumatic Piece Ejecting Device

- Chuck Rising Device

- In-Process Measure Device for Parts – Renishaw

- USB / Ethernet Interface

- 3D Data Module for Working Area

Machine Benefits

Technical Machine Benefits

- Counter spindle: integrated spindle – 5000 rpm, 15/20 kw

- B axis: +/- 110 degrees

- Partial hollow diameter: 67 mm

- 3 jaw power clamping with through hole and jaw quick-change system

- Different pressure clamping for counter spindle

- 48 tool magazine

- Automatic tail-stock

- Tool measuring device: laser nc4 includes calibration software

Extra Information

C Axis with Hydraulic Brake (Counter Spindle) Basic Slide (Z3) Connection for Oil Mist Extractor Coolant Spray Gun

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing