Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

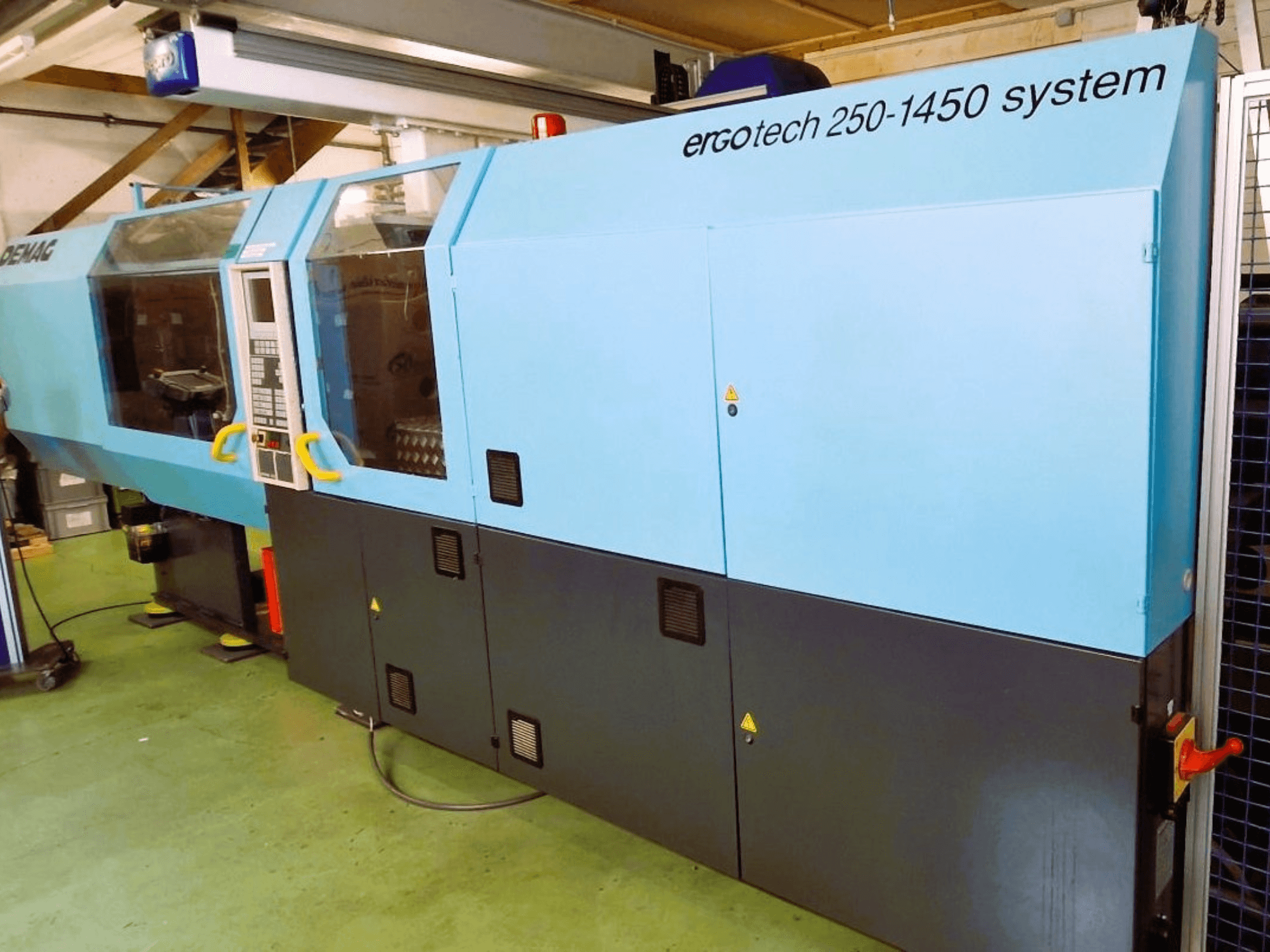

DEMAG - Ergotech System 250 - 1450CH-INJ-DEM-1995-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used DEMAG Ergotech System 250 - 1450 For Sale

This DEMAG Ergotech System 250 - 1450 was manufactured in 1995. A robust hydraulic injection moulding machine, it features a clamping force of 2500 kN and a screw diameter of 70 mm. It's equipped with a Sepro robot, energy-saving DFE hydraulic control pump, and a modular design for versatile applications. The machine dimensions are 6.4 × 1.9 × 2.3 m, and it includes a comprehensive operator terminal with a 10-inch LCD display. Contact us for more information about this machine.

Overview

- brand: DEMAG

- year: 1995

- MODEL: Ergotech System 250 - 1450

- application type: Injection Moulding

- Location: Switzerland

- machine type: Hydraulic Injection Moulding Machine

Technical Information - DEMAG Ergotech System 250 - 1450

Dimensions

- Machine Height: 2300 mm

- Machine Length: 6400 mm

- Machine Weight: 13500 kg

Additional Information

Clamping unit:

Clamping force: 2500 kN (holding force 2750 kN)

Opening stroke max.: 675 mm

Tool/mold height: 330–710 mm

Clear tie-bar spacing: 630 × 630 mm

Max. spacing of tool clamping plates: 950 × 950 mm

Max. mold weight: 3300 kg

Ejector stroke: 200 mm

Ejector force: 80 kN (retraction force 35 kN)

5-point double toggle lever, compact; oil-lubricated toggle levers with optimized pulses

Support for moving platen; height-adjustable mold mounting plates

Induction-hardened tie bars (4-fold), upper columns extendable

3 mold opening/closing speeds; clamping force adjustable on IBED

Hydraulic mold ejector; position measuring system for mold plates

Automatic mold cooling shutdown in case of malfunctions

Injection unit:

Injection unit: 1450

Screw diameters: 50 / 60 / 70 mm (currently equipped: 70 mm)

L/D ratio: 20:1 (all screw cylinders)

Max. dosing stroke: 270 mm

Active screw retraction system; hydraulic screw retraction after holding pressure or plasticizing

Separately heated cylinder zones; 5 self-optimizing temperature control loops (cylinder & nozzle)

Speed control via 10 support points (polygon profile)

Screw speed control via 6 stages

Holding pressure control: 10 stages (polygon profile)

Injection via displacement measuring system (rapid/creep)

Adjustable back pressure; cushion monitoring during holding pressure

2 3-speed injection molding system; two-stage ejection speed

Nozzle:

Nozzle stroke max.: 440 mm

Nozzle immersion depth: 40 mm

Nozzle contact force: 110 kN

Performance/data:

Max. part weight (PS): 927 g

Filling hopper capacity: 110 L

Oil tank capacity: 700 L

Pump unit: 37 / 45 kW

Electrical connection: 380 V / 50 Hz

Controls and HMI:

Fully controlled injection molding machine; modular design

Energy-saving DFE hydraulic control pump

Cylinder change system with automatic data conversion

Built-in ramp function for mold opening/closing

Operator terminal IBED with 10" LCD and 3.5" floppy disk drive

Setpoint input in bar, cm³, mm/s, or %

Graphic support for injection profiles

PDE process data acquisition (20 parameters + 100 cycle graphs); process control

Plain text error diagnostics

Process data transfer to other ERGOtech machines

On/off program with ejection spraying

Help function with diskette

Interfaces and connections:

EOAT/peripheral bus for device connection

V24 interface for hardcopy printer; printer program + hard copy

Handling interface VDMA 24465 (32-pin)

Tool protection interface (ejector plate lock)

Tool connection DIN standard

Socket combination:

2× 220 V / 2× 380 V + automatic shut-off

2× 220 V + 1× 380 V socket (SO)

Pneumatic valves (3/2) for tool mounting plate

Cooling water control: 8-way (expandable to 12-way)

Visual fault indicator (flashing light)

Paint finish:

Lower part anthracite; upper part blue/green/light gray

Additional equipment

Sepro robot (handling)

Horizontal cross-stroke X: total 3000 mm (X1 = 2580 mm / X2 = 420 mm)

Drive: servo motor

Max. travel speed: 4000 mm/s

Output side: rear of machine

Fixed base height approx.: 480 mm

Material hopper

Temperature controller with graphical recording

Cooling water control unit: 8-way, expandable to 12-way

Resilient machine mounting (vibration-damping feet)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing