Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

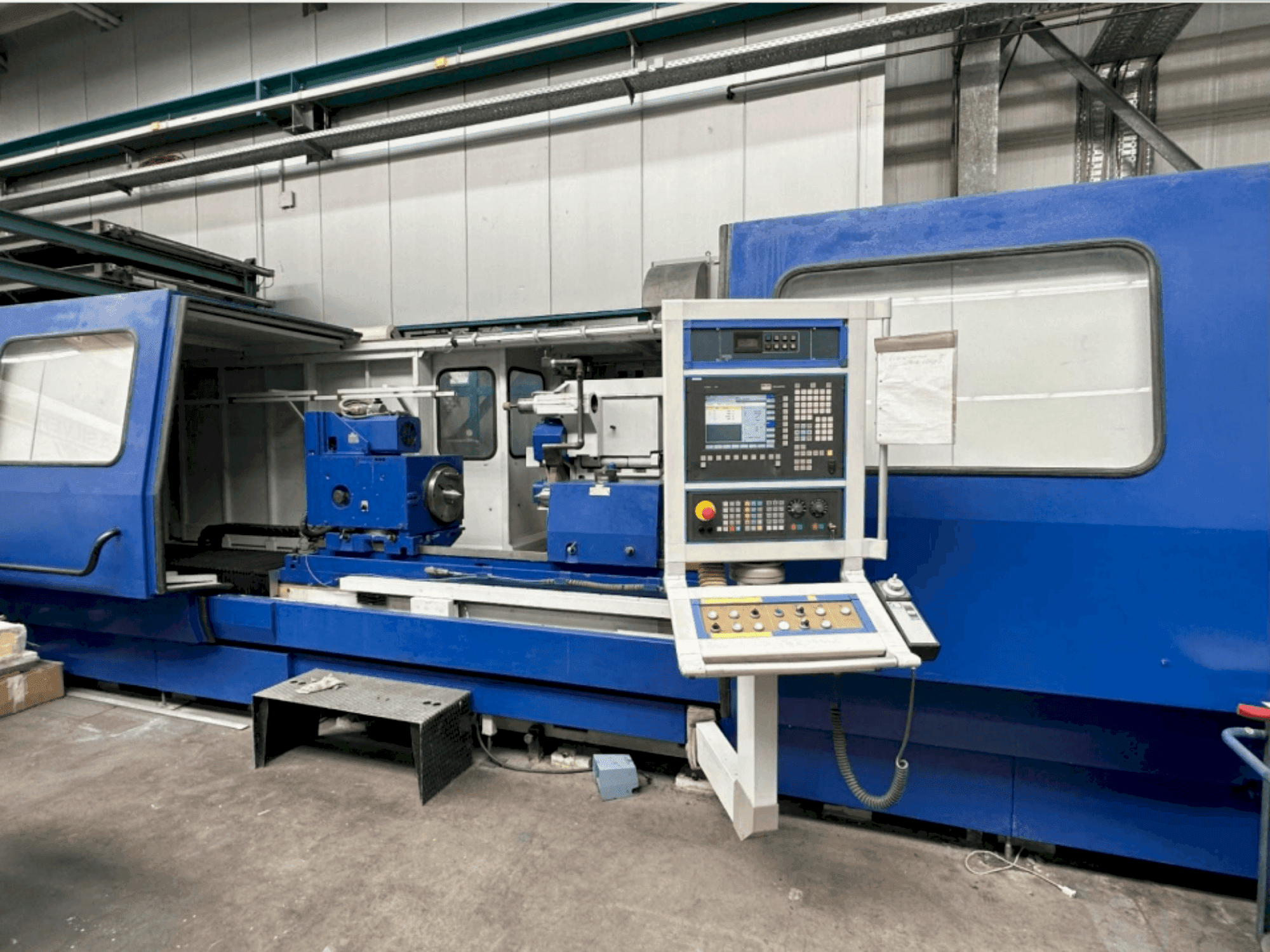

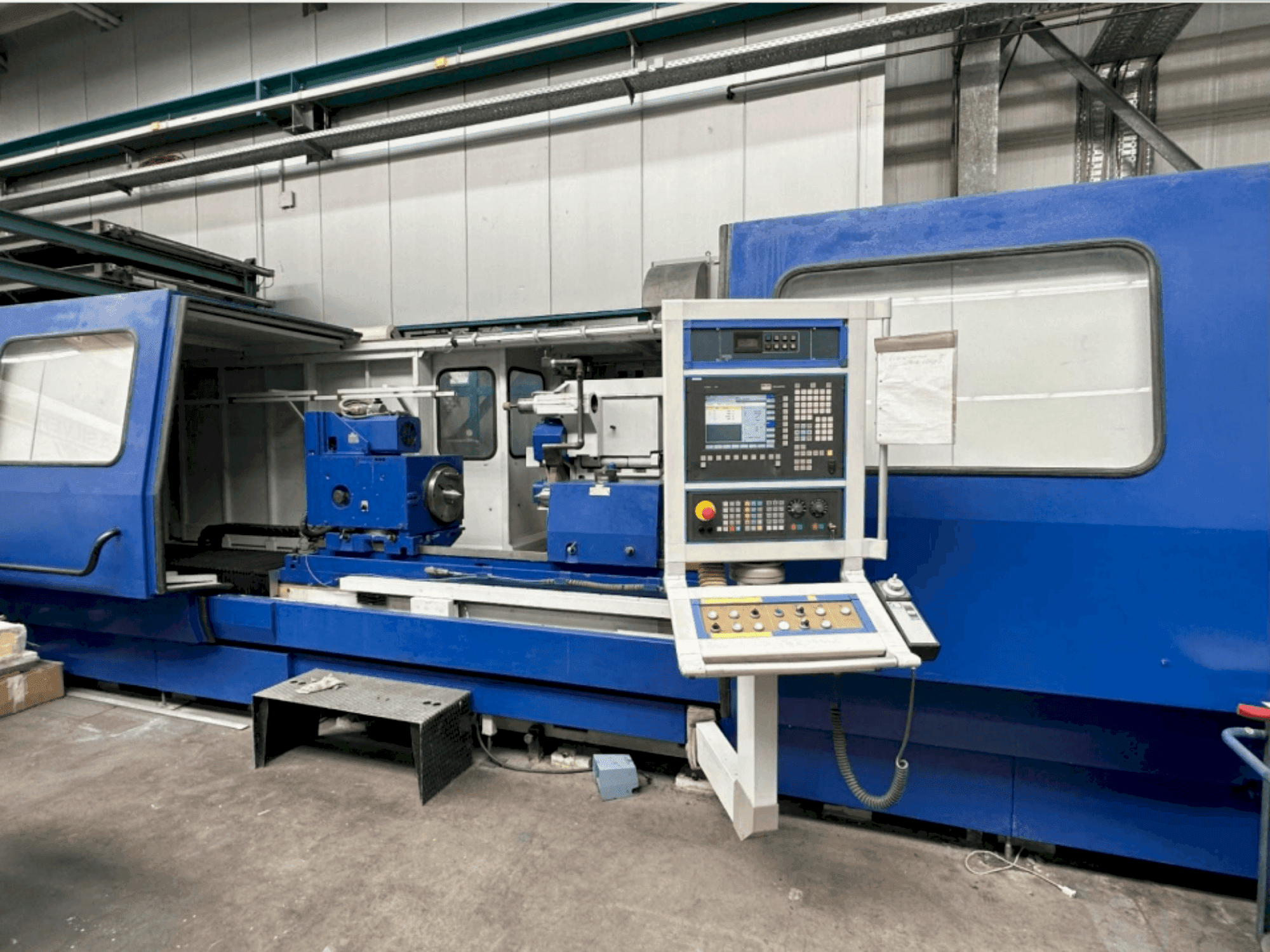

Cetos - BUC 63C CNC/2000DE-GRI-CET-2003-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Cetos BUC 63C CNC/2000 | Grinding

This 4-axis Cetos BUC 63C CNC/2000 was manufactured in 2003. A robust cylindrical grinding machine, it features a center distance of 2000 mm, a swing diameter of 630 mm, and can handle a maximum workpiece weight of 4000 kg. Equipped with the advanced Sinumerik 840D Powerline control system and a Resy coolant management system, it ensures precision and efficiency. If you are looking to get high-quality internal cylindrical grinding capabilities consider the Cetos BUC 63C CNC/2000 machine we have for sale. Contact us for more information.

Overview

- brand: Cetos

- year: 2003

- MODEL: BUC 63C CNC/2000

- application type: Grinding

- Location: Germany

- machine type: Cylindrical Grinding Machine

- control unit brand: SIEMENS

Technical Information - Cetos BUC 63C CNC/2000

Control Unit

- Control Brand: SIEMENS

- Control Model: 840D Powerline

Dimensions

- Machine Depth: 7700 mm

- Machine Height: 2960 mm

- Machine Weight: 13805 kg

Technical Specification

- Spindle Power: 19 kW

- Spindle Speed: 1675 RPM

Additional Information

Additional equipment

- Equipped with an electrical quill travel of 80 mm (overhauled)

- Grinding Spindle: Overhauled

- Grinding Wheel Handling: Broad grinding wheel support, manual steadies, wheel-changing facility with a grinding wheel stand

- Resy coolant management system

- Automatic and manual steadies included

- The machine has been mechanically overhauled

- The bed and grinding spindle are in refurbished condition

Machine Benefits

Qualitative Machine Benefits

- Technical machine benefits: mechanically overhauled, broad grinding wheel support

- Qualitative machine benefits: overhauled components including tailstock with electric quill stroke, spindle head, grinding spindle, and machine bed

- Possibility to grind conical holes during internal grinding because of rotated headstock

- The maximum workpiece weight for grinding without tailstock or steady rest is 300 kg, including clamping device, according to the operating instructions

- The maximum diameter of the internal grinding wheel is 57 mm. See page 8. 185 of the operating instructions.

- The machine has dressing systems in jog or automatic mode. See page 8. 43 of the operating instructions.

- Marposs measuring probe is installed.

Technical Machine Benefits

- Center distance: 2000 mm

- Swing diameter: 630 mm

- Maximum workpiece weight: 4000 kg

- Workpiece drm: 630 mm / workpiece x: 2000 mm

- Power supply: 3x400v, 50hz / control voltage: 230v ac, 24v dc / total power consumption: 65/80 kva / machine bed material: cast iron (gray iron)

- Tailstock equipped with electrical quill travel and adjustable clamping force / grinding spindle swivel range: +30° to -10° / automatic infeed range: 0. 0005 mm to 380 mm / rapid traverse speed: 10,000 mm/min / pneumatics: working air pressure: 0. 5 mpa, air consumption: 800 l/min / lubrication: grinding spindle lubrication and guideways and infeed mechanisms lubrication

- The headstock can be equipped with a three-jaw chuck

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing