Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

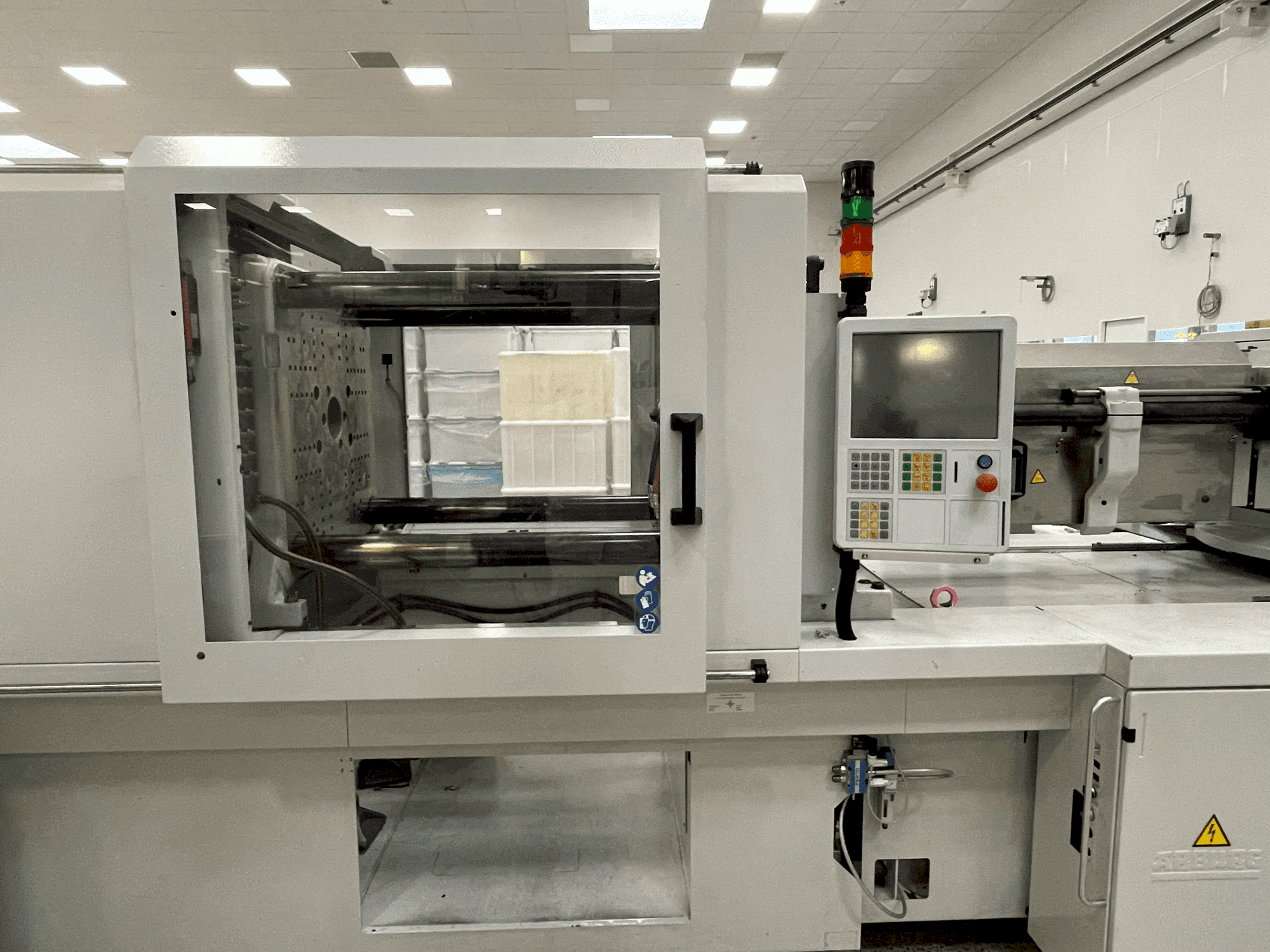

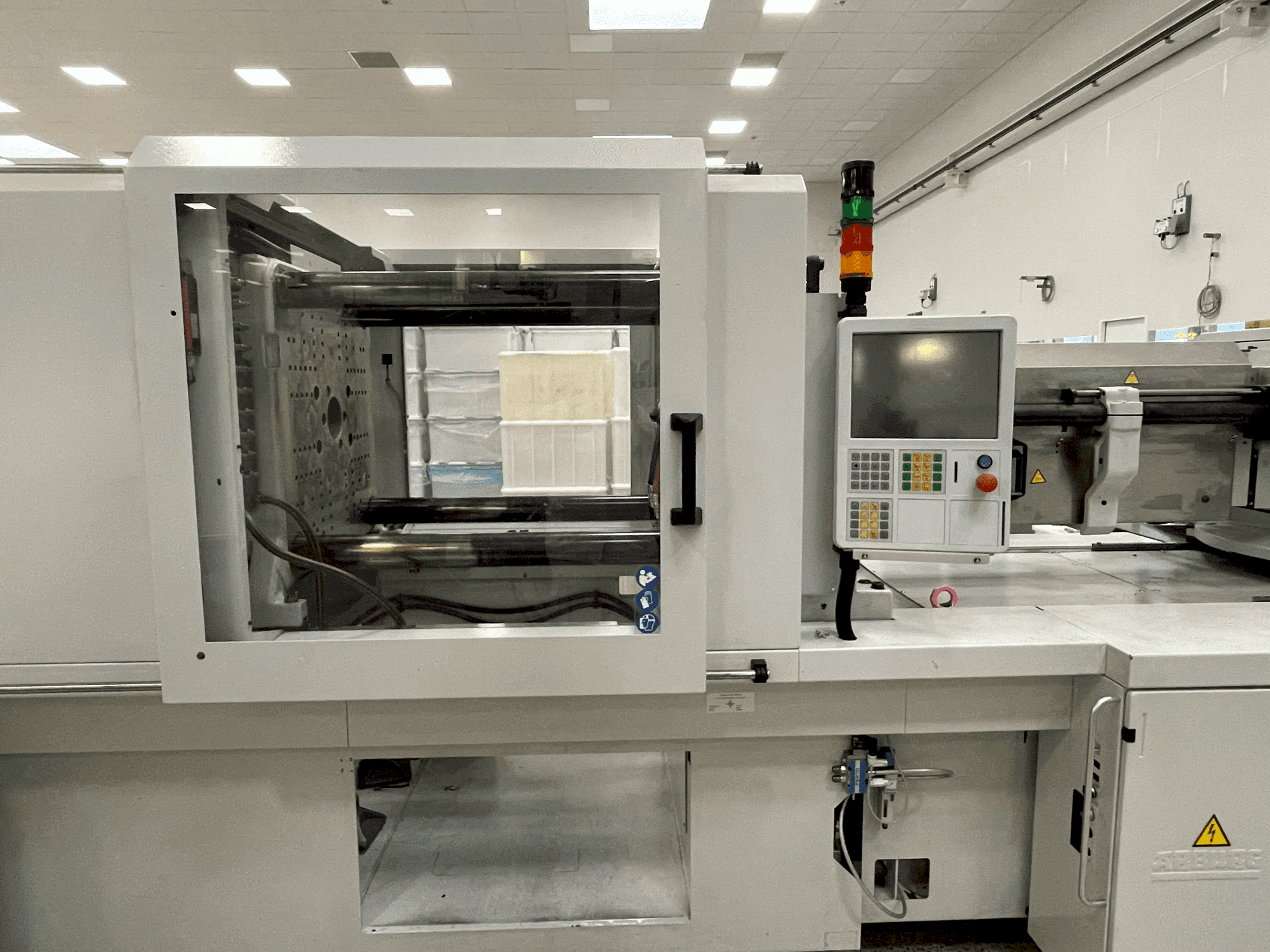

Arburg - Allrounder 570 H 2000-1300DE-INJ-ARB-2014-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ARBURG Allrounder 570 H 2000-1300 Injection Moulding Machine

This ARBURG Allrounder 570 H 2000-1300 HIDRIVE Injection Moulding Machine was manufactured in 2014 in Germany. It has a clamping force of 2000 kN and is equipped with thermoplastic cylinder of 60mm with long barrier screw (open nozzle 60 mm, nozzle tip radius 15, heating tape for open nozzle). In addition it features a servoelectric mold height adjustment with automatic clamping force control, a central clamping platen set Ø 125 mm, a maximum installation dimension increased to 650 mm and injection pressure increased by 10% (max. 2500 bar depending on screw). See overview of full configuration attached as PDF (DE) below. Important remark: The injection unit is leaking, there is a cost estimate from Arburg for approx. 15,000 euros net including assembly. This defect has not yet been rectified as the machine is not currently being used. The sale does not include the housing, any hoppers visible in the pictures or other accessories. The machine has already been taken off the grid and cannot be inspected in operation. Pump hours at at 63,202 and operating hours at 50,361 h.

Overview

- brand: Arburg

- year: 2014

- MODEL: Allrounder 570 H 2000-1300

- production hours: 63202

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

- control unit brand: ARBURG

Technical Information - Arburg Allrounder 570 H 2000-1300

Control Unit

- Control Brand: ARBURG

- Control Model: SELOGICA direct

Technical Specification

- Clamping Force: 2000 kN

- Screw Diameter: 60 mm

Additional Information

Additional equipment

- Equipment package Extended monitoring

- Equipment package Extended travel movements

- Equipment package Production control

- Equipment package Optimization/ operating aids

- Equipment package Quality assurance

- Documentation equipment package

Machine Benefits

Qualitative Machine Benefits

- Injection unit adapted for long plasticizing units

- Servoelectric mold height adjustment with automatic clamping force control

- Injection pressure increased by 10%; screw-dependent max. 2500 bar

- Nozzle contact force regulated

- 12 electrical heating control circuits for mold heating

- Freely programmable ramps for hydraulic ejector

- Water-cooled switch cabinet

- Machine protection designed for operation with and without multi lift

- Low-current switch cabinet 800 x 800

Technical Machine Benefits

- Reinforced screw coupling - coupling geometry multi-tooth

- Thermoplastic cylinder 60 mm long with barrier screw

- Drive unit with 30 kw motor and 61. 11/min loading volume flow

- Technology level storage drive // thermoplastic processing

- Open nozzle 60 mm // nozzle tip radius 15 // heating band for open nozzle

- Central clamping platen set Ø 125 mm

- Maximum installation dimension increased to 650 mm

- Ejector pressure p /q controlled

- Continuous oil cooling and filtration

- Robot system interface (to euromap 67)

Extra Information

50-pin Extension robot interface (Euromap 12 and 67) F9264, 4 programmable inputs/outputs on terminal strip, Socket outlet vert. 1 CEE, 1 Schuko additional, Cutting unit Temperature control unit WKZ 20 mA, Printer interface serial USB, Compact Flash interface for data record storage, Operating authorization with chip card according to EUROMAP 65, Holder for PC keyboard with USB connection, Acoustic fault display, AED - electrom. Dosing drive, Interface Protection of the safety fence door (EUROMAP 73), Parallel connection for heating tape Nozzle tip or adapter, Approach parameters, Interface coloring unit, Shut-off valve for cooling water in feed 1, Elevated oscillating elements (100 mm machine elevation), Machine-related cooling circuits controlled, aXw Control ScrewPilot , CD Operating instructions and spare parts list , Without granulate container 50 L, Without cooling water distribution for mold, Ejector plate connection Safety device, Socket outlet vert. 1 CEE,1 Schuko, Control extension for special signals, Machine in special paint finish

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing