Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

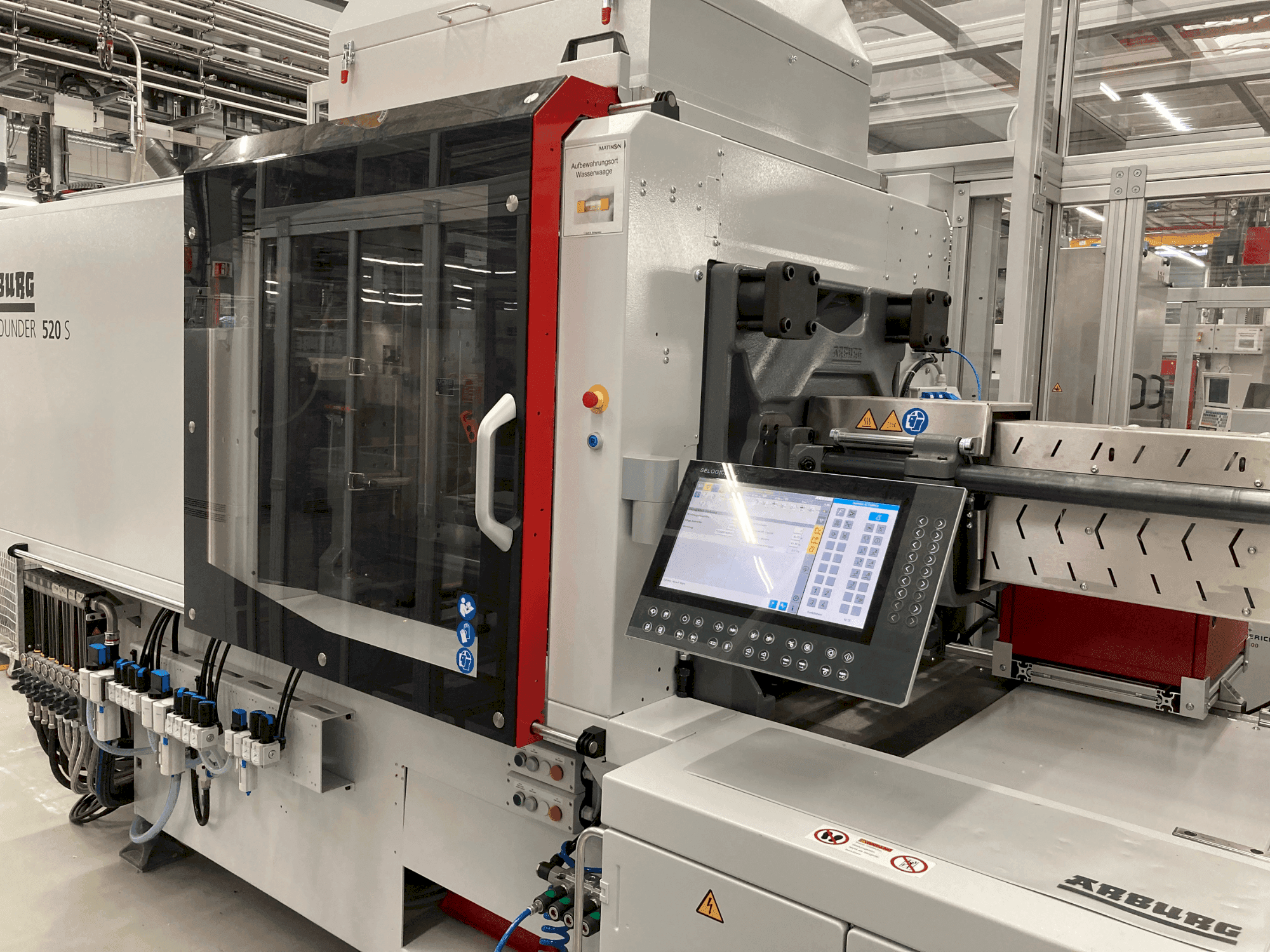

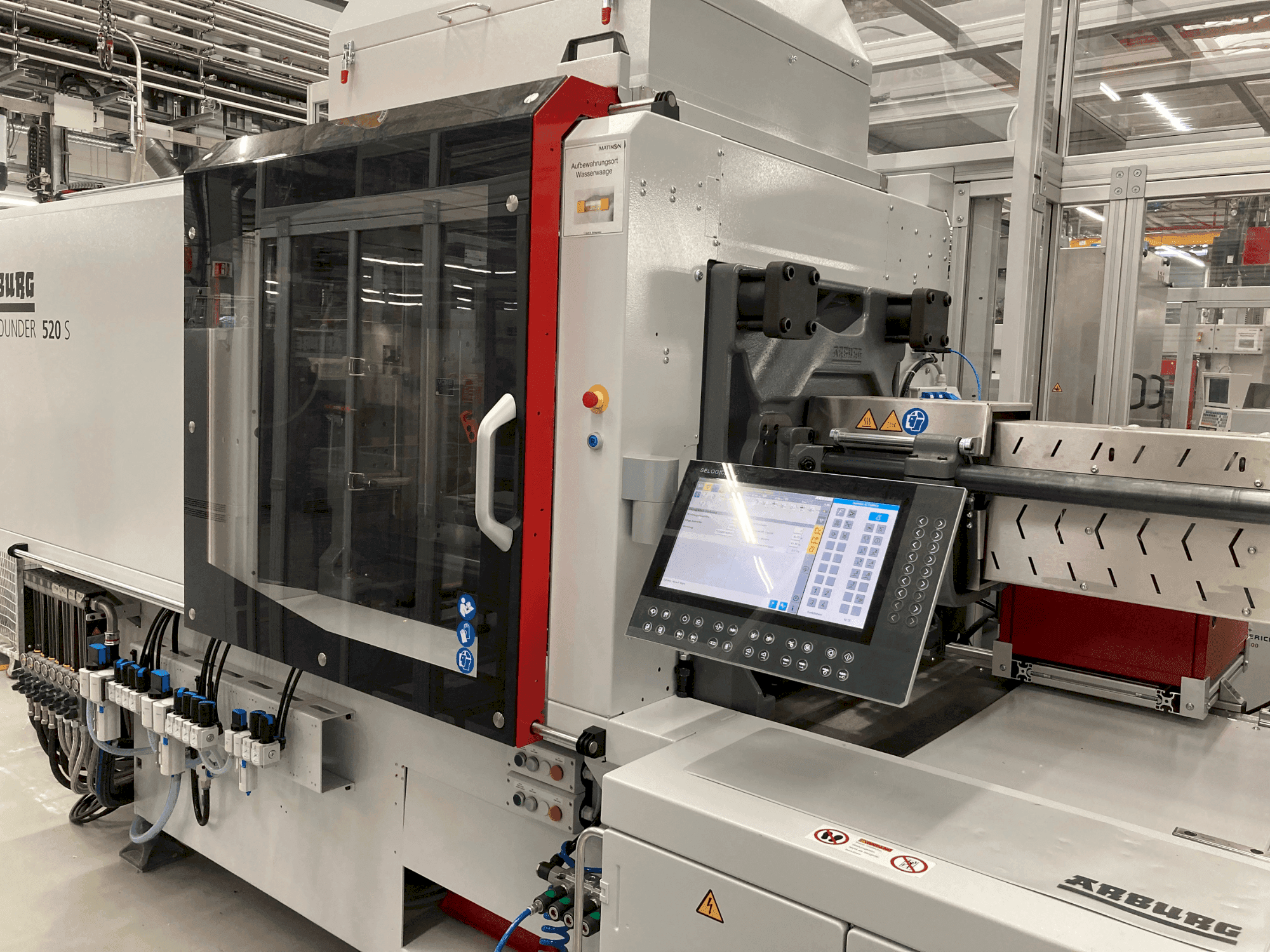

Arburg - Allrounder 520 S 1600-400DE-INJ-ARB-2024-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Arburg Allrounder 520 S 1600-400 For Sale

This Arburg Allrounder 520 S 1600-400 was manufactured in 2024. A hydraulic injection moulding machine, it represents a reliable option for precision plastic processing. Consider the opportunity to buy this Arburg Allrounder 520 S 1600-400 hydraulic injection moulding machine. Contact us for more information.

Overview

- brand: Arburg

- year: 2024

- MODEL: Allrounder 520 S 1600-400

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Arburg Allrounder 520 S 1600-400

Dimensions

- Machine Depth: 7000 mm

Technical Specification

- Clamping Force: 1600 kN

Additional Information

Additional equipment

- Optional: Automationsystem KUKA Cybertech (2 KUKA robots, KR 10 + KR22)

- 4x Temperature Control Units: Thermo 5

- Language Options: German, English, Czech

- Maximum opening: 575 mm / Maximum plate distance: 1025 mm / Maximum ejector length: 175 mm

- Coupling diameter: 32 mm / Center ring diameter: 125 mm

- Valve gate: 6

- HK Control points: 42

- Number of hydraulic core pulls (Fixed side): 1 / Number of hydraulic core pulls (Moving side): 2 / Number of pneumatic core pulls (Fixed side): 2

Machine Benefits

Technical Machine Benefits

- Operating voltage: 400 v, 3-phase, 50 hz

- Control voltage: 230 v, 50 hz

- Control voltage: 24 v

- Motor/heating rated current: 160/150 a

- Total connected load: 197 kw

- Tonnage: 160 tons

- Firing force 1600 kn

- The arburg machine is available for individual purchase.

- Alternatively, it can be acquired as a complete system, including either a kuka kr 22 or kuka kr 10 industrial robot.

- An optional configuration with both robots integrated into the setup is also possible.

Extra Information

Machine still under power // Machine Specifications: • Type of control: Selogica ND • Tie bar distance: 520 • Tonnage group: 160 to • Number of components: 1K • Maximum clamping force: [kN]: 160 • Minimum tool height: [mm]: 450 • Maximum opening: [mm] 575 • Maximum plate distance: [mm]: 1025 • Ejector specifications: o Maximum ejector length: [mm]: 175 o Coupling diameter: [mm]: 32 • Index shaft: o Diameter: [mm]: x o Distance: [mm] - • Center ring diameter: [mm]: 125 • Injection Unit: • Aggregate 1: o Size: 400 o Screw diameter: [mm]: 35 o Maximum shot volume: [ccm]: 141 o Maximum injection pressure: [bar]: 2500 • Aggregate 2: / o Size: - o Screw diameter: - o Maximum shot volume: [ccm]: - o Maximum injection pressure: [bar]: - • Aggregate 3: / o Size: [Specify] o Screw diameter: [mm] o Maximum shot volume: [ccm] o Maximum injection pressure: [bar] Valve gate (number) : 6 HK Control points Number (measuring points): 42 Booster (kompresor): 1/0 = yes/no: 0 Internal pressure: 1 Number of hydraulic core pulls (Fixed side): 1 Number of hydraulic core pulls (Moving side): 2 Number of pneumatic core pulls (Fixed side): 2 Number of pneumatic core pulls (Moving side): - Ionization: 1/0 = yes/no: 0 Generator available: 1/0 = yes/no: 0 Temperature Control Units: • Temperature control unit 2 [°C]: 160 • Temperature control unit 3 [°C]: 160 • Temperature control unit 4 [°C]: 160 • Temperature control unit 5 [°C]: 160 • Temperature control unit 6 [°C]: - • Temperature control unit 7 [°C]: - • Temperature control unit 8 [°C]: - • Number of thermolators: 4 • Thermolator max temperature [°C]: 160 • Serie: Serie 5 HB Therm • Type of controller: Panel 5 extren • Cold water cycles max (only for tool, fixing site): 2 • Cold water cycles max (only for tool, moving site): 2 • Temperature sensor (mold): 1/0 = yes/no: 1 • Material Dryer at Machine1/0 = Yes/No: 1 • Interface Coloring Device 1/0 = Yes/No: 0 Robot: KUKA KR 22 Robot Payload [kg]: 22 Quick Coupling (1 = QCA90/ 2 = QCA150): 2 • Communication Connector (1 = Sub-D/ 2 = Double Sub-D): 2 • Robot Vacuum Circles Nr.: 8 • Robot Gripper Circles Nr.: 8 • Robot Axes: A1, A2, A3, A4, A5, A6 • Conveyor System: • Tray type: Standard/with tray stopper (1 or 2 lanes): Standard and Tray • Conveyor belt with tray stopper (1 or 2 lanes): 2 • Direction: Lengthwise (2) or transverse (1): 2 • Additional Specifications: • Dimensions: o Width: [m]: 6 o Length: [m]: 7 o Area: [m²]: 42 • Cable cross-section: [mm²]: - • Water connection details: o Size: [inch]: - o Number of points: [Number]: - • Energy consumption: [kW/h]: - • Machine weight: [kg]: - • Oil filling quantity: [l]: - • Automation Details: • Automation integrated: Yes/No: 1 Automation description: [Details]: Automation for Lightring EVA 2 Seite MOPF - Cleaning Tayfun Clean - cooling table - Ultrasonic punching - second KUKA KR10

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Documents

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing