Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

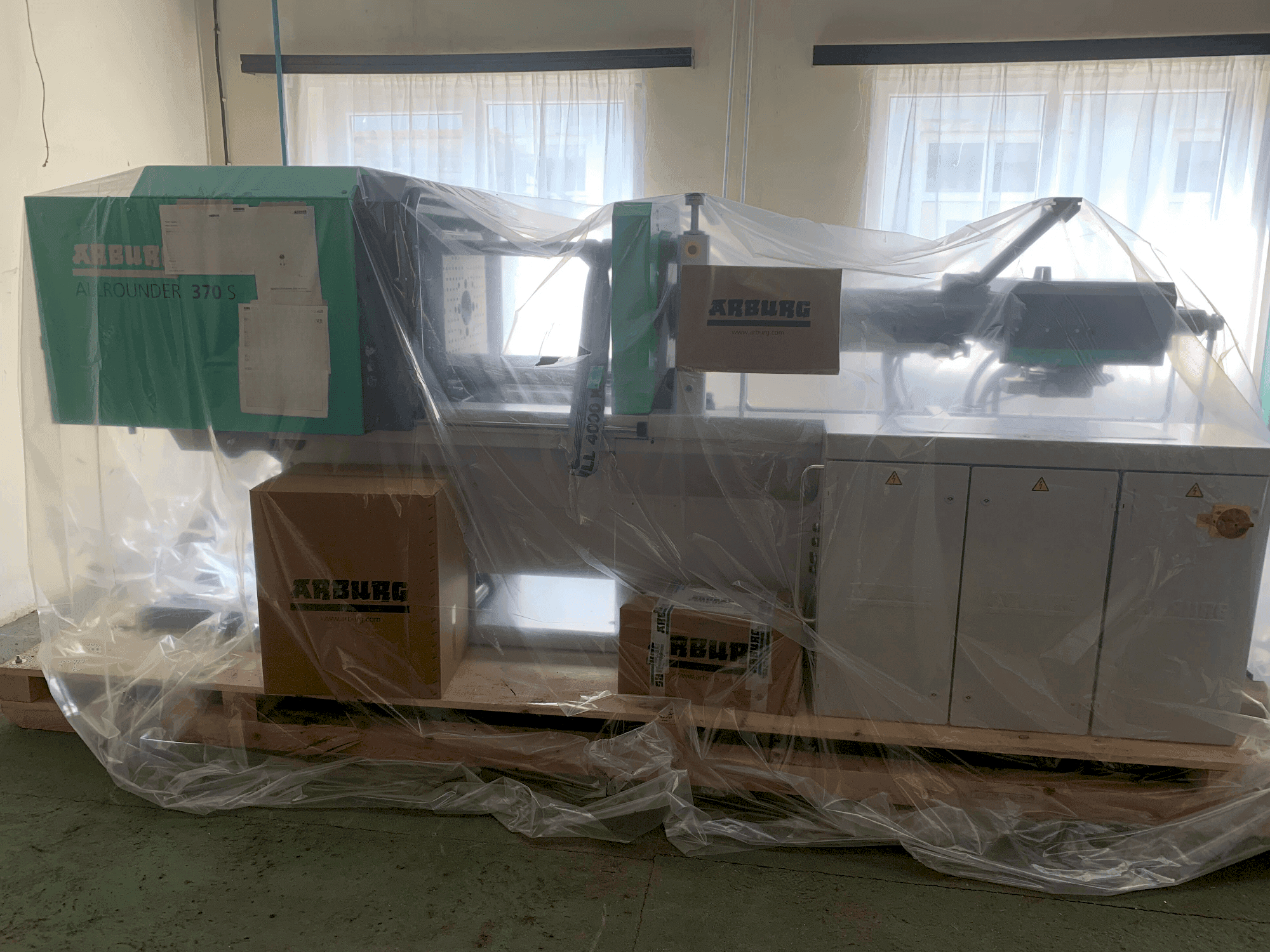

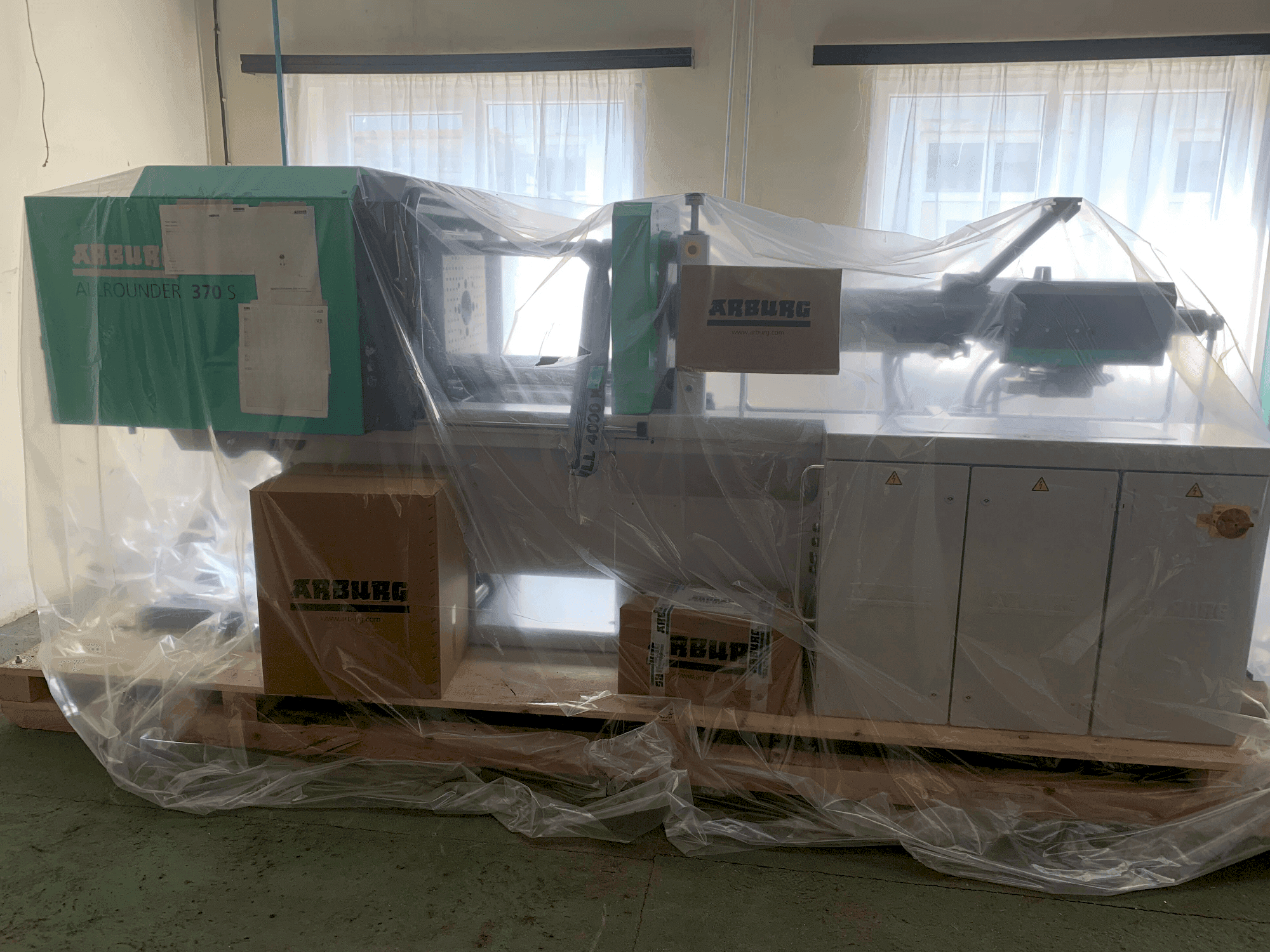

Arburg - ALLROUNDER 370 S 600-290 UHU-INJ-ARB-2022-00001

Do you have further questions? Contact us.

Sergi Guardia

+49 162 4027635

s.guardia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- Arburg 370 S 600-290 U Injection moulding machine

This Arburg 370 S 600-290 U Injection moulding machine was manufactured in the year 2022 in Germany. It is new, never used and still in original packaging. With a clamping force of 600 kN, 290 injection unit and screw diameter of 35mm (armored, highly wear-resistant screw) it is a compact, fully hydraulic clamping system - ideal for reliable and precise reproducibility in injection moulding operations. The closing unit can be tilted from horizontal to vertical. To be considered that machine comes without position control.

Overview

- brand: Arburg

- year: 2022

- MODEL: ALLROUNDER 370 S 600-290 U

- application type: Injection Moulding

- Location: Hungary

- machine type: Hydraulic Injection Moulding Machine

- control unit brand: ARBURG

Technical Information - Arburg ALLROUNDER 370 S 600-290 U

Control Unit

- Control Brand: ARBURG

- Control Model: SELOGICA ND

Dimensions

- Machine Depth: 1475 mm

- Machine Height: 11920 mm

- Machine Weight: 3300 kg

Technical Specification

- Clamping Force: 600 kN

- Max. Shot Weight: 132 g

- Screw Diameter: 35 mm

Additional Information

Machine Benefits

Qualitative Machine Benefits

The machine is new, never used and still in original package

The closing unit can be tilted from horizontal to vertical

Technical Machine Benefits

Central, convertible, swivelling injection unit as complete assembly group

Plasticising unit in modular design, with central coupling and adaptive temperature regulation

Plasticising cylinder in wear resistant execution, injection through fixed mould platen

Compact, fully hydraulic clamping system with 4 individually removable tie bars

Clamping unit without hoses, hydraulics close to the use for precise drive of the axes

All axes of the mould clamping unit are programmable and regulated in their movements

Space-saving, compact design

Mould protection monitoring via ejector platen safety switch (interface)

Intuitive selogica nd control system – data sets are fully compatible with the proven selogica

Hierarchical structure and graphical sequence programming with real-time plausibility check, identical to selogica controller

Extra Information

Equipped with armored, highly wear-resistant d35 mm screw.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Sergi Guardia

Payment Terms

Payment in advance

Asset Financing